Surface coating liquid of hot galvanized plate and preparation method of high-humidity resistant hot galvanized passivation plate

A technology of hot-dip galvanized sheet and surface coating, applied in the direction of metal material coating process, etc., can solve the problems of outstanding environmental protection and difficulty in application of hot-dip galvanized steel sheet, and achieve the effect of excellent corrosion resistance and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

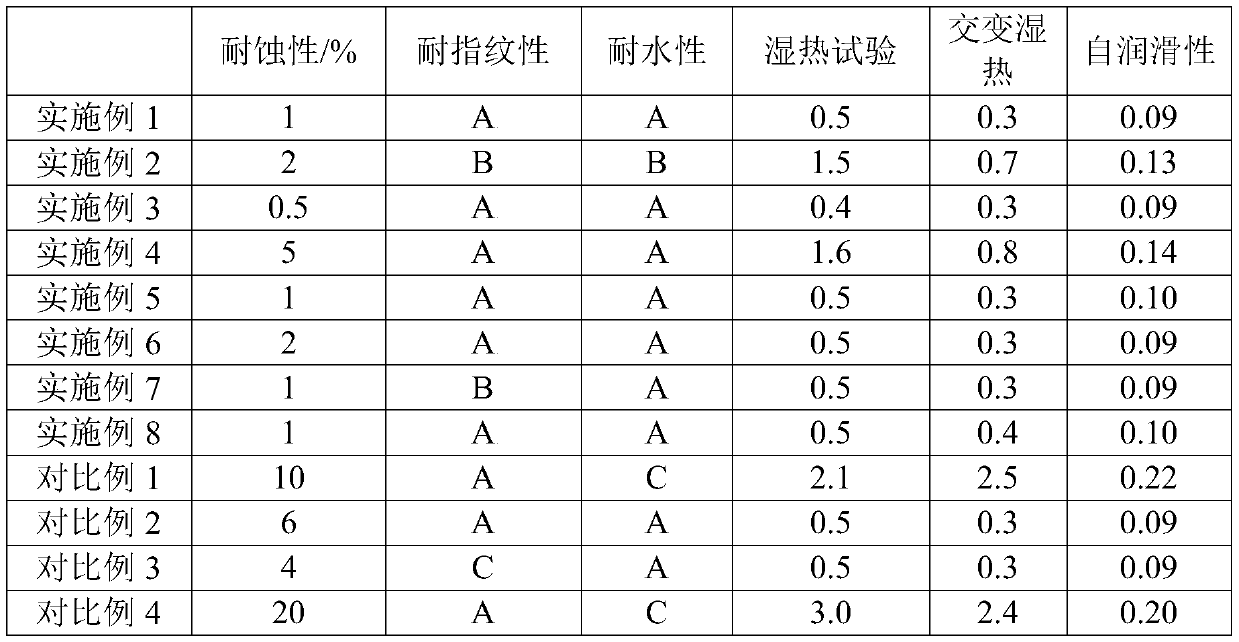

Examples

Embodiment 1

[0041] The preparation of the surface coating solution of the hot-dip galvanized sheet in this embodiment: the water 100, the fluorine-containing auxiliary agent 5, the corrosion inhibitor 6, the silicon-containing substance 18, and the water-based organic substance 30 are mixed uniformly under normal temperature stirring conditions in parts by weight, Among them, the fluorine-containing auxiliary agent is aqueous fluorocarbon emulsion and fluorotitanic acid (the weight ratio of the two is 4:1), and the corrosion inhibitor is sodium hexametaphosphate and potassium molybdate (the weight ratio of the two is 2:1), containing The silicon material is colloidal silica, and the water-based organic matter is water-based acrylic emulsion;

[0042] Preparation of hot-dip galvanized passivation sheet resistant to high humidity environment: roll coating the above coating solution on a hot-dip galvanized steel strip, and cure it for 15s at a curing temperature of 105° C. Hot-dip galvanized...

Embodiment 2

[0044] The preparation of the surface coating liquid of the hot-dip galvanized sheet of this embodiment: the content of each component is as shown in Table 1, and the others are the same as in Example 1;

[0045] Preparation of hot-dip galvanized passivation plate resistant to high humidity environment: the same as in Example 1.

Embodiment 3

[0047] The preparation of the surface coating liquid of the hot-dip galvanized sheet of this embodiment: the content of each component is as shown in Table 1, and the others are the same as in Example 1;

[0048] Preparation of hot-dip galvanized passivation plate resistant to high humidity environment: the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com