Hazardous waste disposal method

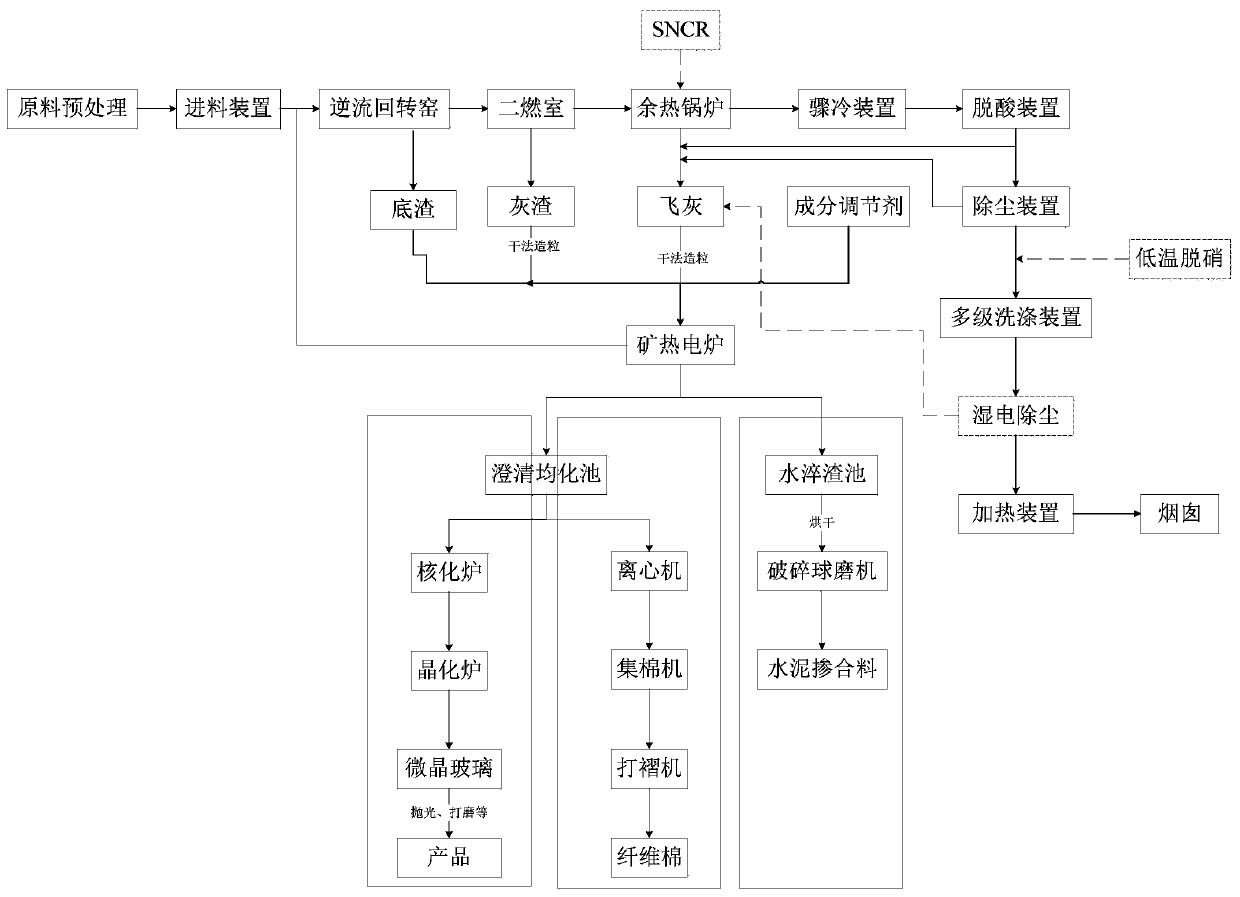

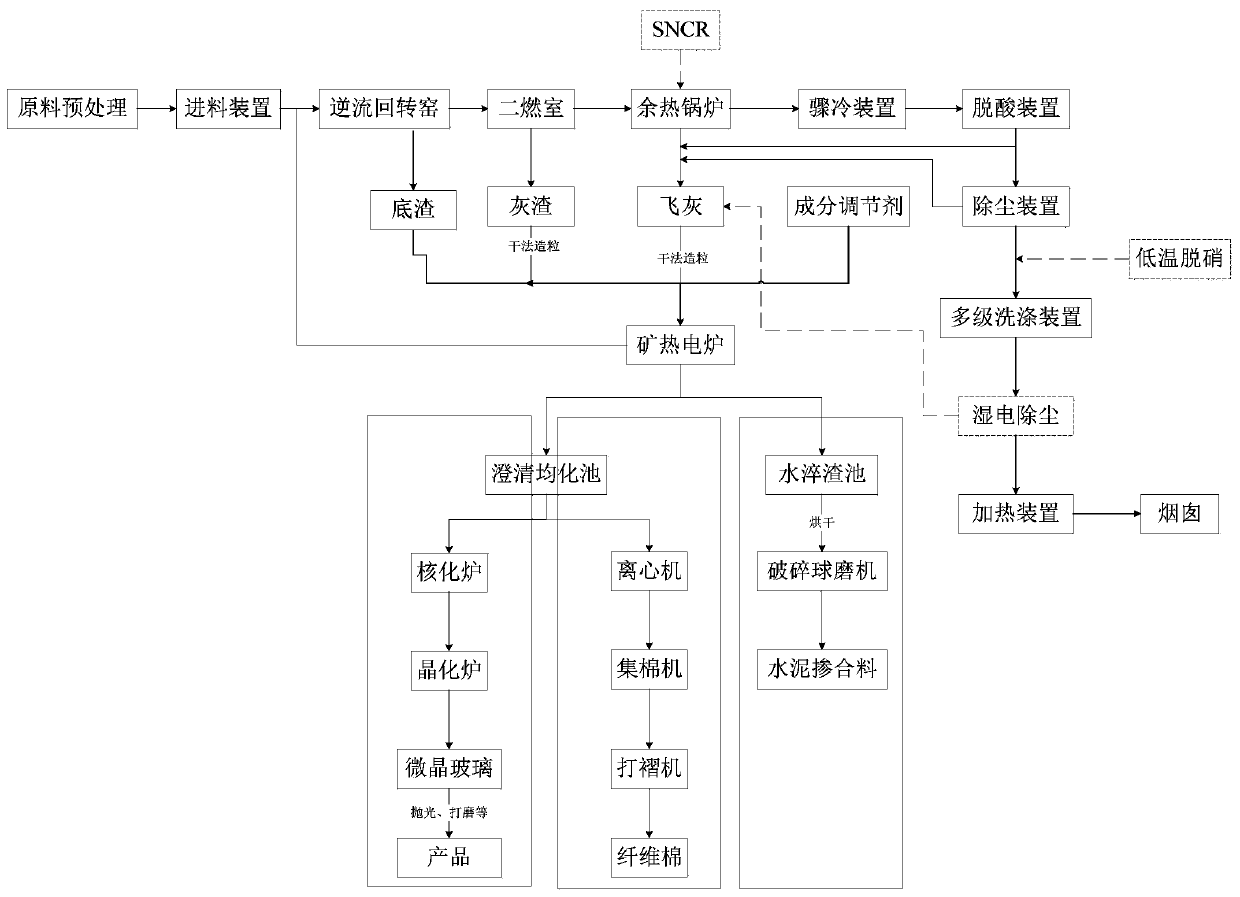

A technology of hazardous waste and treatment method, which is applied in the field of hazardous waste treatment, can solve the problems of excessive heavy metal toxicity, low thermal reduction rate and excessive dioxin content in ash and slag, and achieve the effect of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) The medical waste, rectification residue and organic resin waste are crushed and pretreated, and pushed into the countercurrent rotary kiln through the push rod feeding device for incineration; at the same time, the waste organic solvent and waste mineral oil, etc. Liquid hazardous waste is sprayed into the rotary kiln for incineration;

[0064] (2) Keep the temperature of the kiln head of the counter-current rotary kiln at about 800°C for the first incineration treatment, keep full combustion, and obtain bottom slag at the kiln head and kiln tail of the rotary kiln, the slag discharge temperature is 800°C, and the thermal ignition loss rate 2.5%, the hot bottom slag is directly sent into the submerged thermal electric furnace through the closed chute;

[0065] (3) The flue gas discharged from the counter-current rotary kiln enters the secondary combustion chamber for the second incineration treatment, and the combustion temperature is 1200°C; the fly ash generated ...

Embodiment 2

[0071] (1) The organic halide waste (HW45), paint waste (HW12) and surface treatment waste (HW17) are crushed and pretreated, and pushed into the countercurrent rotary kiln through the screw feeding device for incineration; at the same time, the spray gun device is used Liquid hazardous wastes such as emulsion (HW09), pesticide waste (HW04) and phenolic waste (HW39) are sprayed into the rotary kiln for incineration;

[0072] (2) Keep the temperature of the kiln head of the counter-current rotary kiln at about 1000°C for the first incineration treatment, keep full combustion, and obtain bottom slag at the kiln head and kiln tail of the rotary kiln, the slag discharge temperature is 900°C, and the thermal ignition loss rate 2.0%, the hot bottom slag is discharged from the discharge port of the rotary kiln to the sealed material tank, and the bottom slag in the sealed material tank is put into the feed port of the submerged thermal electric furnace through the lifting device;

[...

Embodiment 3

[0079] (1) Medical waste (HW01), asbestos waste (HW36), organic cyanide waste (HW38), spent catalyst (HW50) and distillation residue (HW11) are crushed and pretreated, and pushed into countercurrent rotation by the push rod feeding device Incineration treatment in the kiln; at the same time, liquid hazardous wastes such as waste mineral oil (HW08), pesticide waste (HW04) and waste acid (HW34) are sprayed into the rotary kiln for incineration treatment with a spray gun device;

[0080] (2) Keep the temperature of the kiln head of the counter-current rotary kiln at about 1050°C for the first incineration treatment, keep full combustion, and obtain bottom slag at the kiln head and kiln tail of the rotary kiln, the slag discharge temperature is 950°C, and the thermal ignition loss rate 1.8%, the hot bottom slag is discharged from the discharge port of the rotary kiln to the sealed material tank, and the bottom slag in the sealed material tank is put into the feed port of the submer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com