Soil salinization resisting and growth promoting synthetic fertilizer

A salinization and growth-promoting technology, applied in the field of growth-promoting comprehensive fertilizer, can solve the problems of accelerating the volatilization of water and organic matter in the soil, insufficient release of nutrients, and affecting the normal growth of plants, so as to promote crop growth and promote nutrient Effects of transformation and recycling, improving crop yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

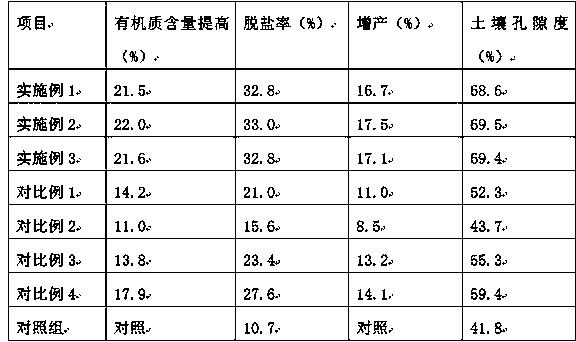

Examples

Embodiment 1

[0017] A growth-promoting comprehensive fertilizer for resisting soil salinization, which is made of the following raw materials in parts by weight: 1200 parts of rice straw, 95 parts of potato dregs, 80 parts of corn dregs, 60 parts of fish pond sludge, 50 parts of horse manure, 0.6 parts of anti-salinization preparation, 1.0 part of aerobic regulator, 40 parts of fermentation bacteria agent, 0.8 parts of auxiliary agent, 1400 parts of water, and its preparation method comprises the following steps:

[0018] (1) Cut the collected rice stalks into lengths ranging from 1-3 cm with a hay cutter, mix them with potato dregs and corn dregs, and dry them at 80°C until the water content is between 5-6%. Then carry out high-pressure high-heat treatment for 10 minutes, and then crush until the particle size is between 0.2-0.3 mm to obtain the crushed straw mixture. Spread fish pond sludge and horse manure to a thickness of 1 cm, dry it in the sun for 4 days, pound After being crushed, ...

Embodiment 2

[0026] A growth-promoting comprehensive fertilizer for resisting soil salinization, which is made of the following raw materials in parts by weight: 1250 parts of rice straw, 98 parts of potato dregs, 85 parts of corn dregs, 65 parts of fish pond sludge, 52 parts of horse manure, 0.7 parts of anti-salinization preparation, 1.1 parts of aerobic regulator, 45 parts of fermentation bacteria agent, 0.85 parts of auxiliary agent, and 1450 parts of water. The preparation method comprises the following steps:

[0027] (1) Cut the collected rice stalks into lengths ranging from 1-3 cm with a hay cutter, mix them with potato dregs and corn dregs, and dry them at 82°C until the water content is between 5-6%. Then carry out high-pressure high-heat treatment for 12 minutes, and then pulverize until the particle size is between 0.2-0.3 mm to obtain a crushed straw mixture. Spread the fish pond sludge and horse manure to a thickness of 1.5 cm, and dry it in the sun for 5 days. After being c...

Embodiment 3

[0035] A growth-promoting comprehensive fertilizer for resisting soil salinization, which is made of the following raw materials in parts by weight: 1300 parts of rice straw, 100 parts of potato dregs, 90 parts of corn dregs, 70 parts of fish pond sludge, 55 parts of horse manure, 0.8 parts of anti-salinization preparation, 1.2 parts of aerobic regulator, 50 parts of fermentation bacteria agent, 0.9 parts of auxiliary agent, 1500 parts of water, and its preparation method includes the following steps:

[0036] (1) Cut the collected rice stalks into lengths ranging from 1-3 cm with a hay cutter, mix them with potato dregs and corn dregs, and dry them at 85°C until the moisture content is between 5-6%. Then carry out high-pressure and high-heat treatment for 15 minutes, and then crush until the particle size is between 0.2-0.3 mm to obtain a crushed straw mixture. Spread fish pond sludge and horse manure to a thickness of 2 cm, and dry it in the sun for 6 days. After being crush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com