Method for constructing micro-nano patterns in high-molecule film lamellas through selective dissolution

A polymer film and micro-nano pattern technology, applied in the field of polymer micro-nano material processing, can solve the problem of few researches on the lamellar micro-nano structure of the polymer film system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

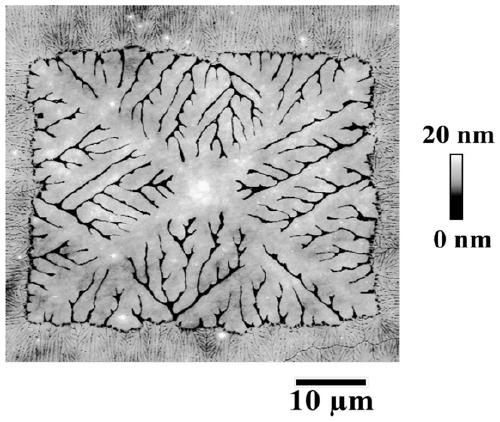

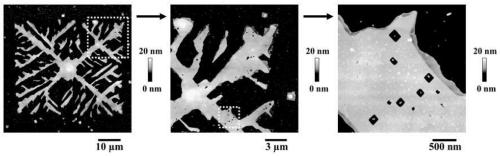

[0061] A method for constructing micro-nano patterns inside polymer thin film lamellar crystals by selective dissolution, the method comprising the following steps:

[0062] (1) Preparation of PEO solution:

[0063] Use acetonitrile as a solvent to dissolve polyethylene oxide with a number average molecular weight of 4.6Kg / mol, then heat on a hot stage to 70°C for 1 hour to completely dissolve PEO in acetonitrile, and configure the mass fraction of PEO in the resulting solution to be 3wt %; then using acetonitrile to dilute the prepared solution to a mass fraction of PEO of 0.3wt%;

[0064] (2) Preparation of PEO film:

[0065] Take the P111 type silicon wafer and irradiate the oxidation treatment with ultraviolet light for 1 hour. After the treatment is completed, place the silicon wafer on a spin coater, and evenly drop the PEO acetonitrile solution (0.01~0.04g) diluted in step (1) on the silicon wafer. Then spin-coat at 4000rpm for 30s, and obtain a polyethylene oxide fil...

Embodiment 2

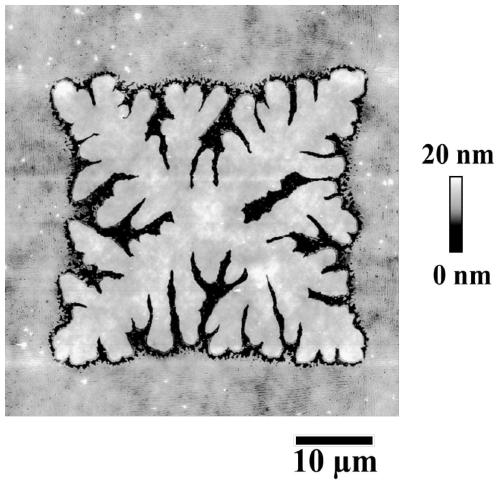

[0074] A method for constructing micro-nano patterns inside polymer thin film lamellar crystals by selective dissolution, the method comprising the following steps:

[0075] (1) Preparation of PEO solution:

[0076] Use acetonitrile as a solvent to dissolve polyethylene oxide with a number average molecular weight of 4.6Kg / mol, then heat on a hot stage to 70°C for 1 hour to completely dissolve PEO in acetonitrile, and configure the mass fraction of PEO in the resulting solution to be 3wt %; then using acetonitrile to dilute the prepared solution to a mass fraction of PEO of 0.3wt%;

[0077] (2) Preparation of PEO film:

[0078] Take the P111 type silicon wafer and irradiate the oxidation treatment with ultraviolet light for 1 hour. After the treatment is completed, place the silicon wafer on a spin coater, and evenly drop the PEO acetonitrile solution (0.01~0.04g) diluted in step (1) on the silicon wafer. Then spin-coat at 4000rpm for 30s, and obtain a polyethylene oxide fil...

Embodiment 3

[0087] A method for constructing micro-nano patterns inside polymer thin film lamellar crystals by selective dissolution, the method comprising the following steps:

[0088] (1) Preparation of PEO solution:

[0089] Use acetonitrile as a solvent to dissolve polyethylene oxide with a number average molecular weight of 4.6Kg / mol, then heat on a hot stage to 70°C for 1 hour to completely dissolve PEO in acetonitrile, and configure the mass fraction of PEO in the resulting solution to be 3wt %; then using acetonitrile to dilute the prepared solution to a mass fraction of PEO of 0.3wt%;

[0090] (2) Preparation of PEO film:

[0091] Take the P111 type silicon wafer and irradiate the oxidation treatment with ultraviolet light for 1 hour. After the treatment is completed, place the silicon wafer on a spin coater, and evenly drop the PEO acetonitrile solution (0.01~0.04g) diluted in step (1) on the silicon wafer. Then spin-coat at 4000rpm for 30s, and obtain a polyethylene oxide fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com