Desulfurization system and desulfurization process based on calcium cycle of cement clinker production line

A cement clinker and desulfurization system technology, applied in the field of desulfurization process, can solve the problems of consumption of limestone mineral resources, energy consumption, and low power consumption in operation, and achieve the effects of reducing SO2 content, solving emission problems, and reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

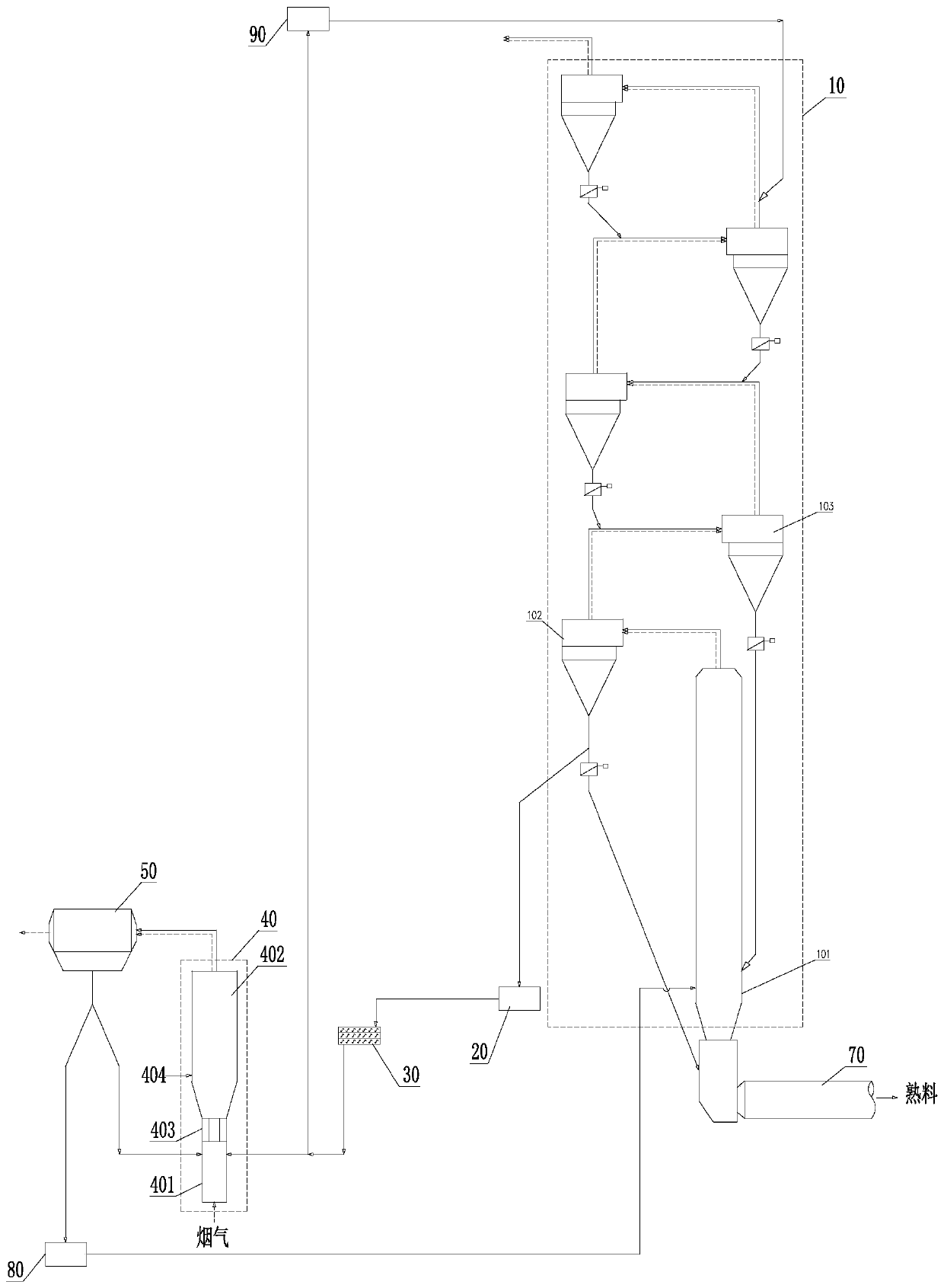

[0091] see figure 1 , an embodiment of the present invention provides a calcium circulation desulfurization system based on a cement clinker production line, including a decomposition unit 10 for decomposing raw meal into active hot raw meal, absorbing SO in flue gas 2The desulfurization unit 40 and the dust collection unit 50 for collecting desulfurization slag. The decomposition unit 10 includes several stages of kiln tail preheaters and decomposition furnaces 101. The kiln tail preheaters use three to seven stages of kiln tail preheaters. This implementation Example preferably adopts a five-stage preheater; it also includes a desulfurizing agent preparation unit connecting the decomposition unit 10 and the desulfurization unit 40, and the desulfurization agent preparation unit utilizes part of the hot raw material decomposed by the decomposition unit to make a desulfurization agent through cooling and digestion, so The desulfurizing agent preparation unit includes a cooling...

Embodiment 2

[0118] The difference from Example 1 is that the active hot raw meal is taken out from the air duct at the outlet of the calciner 101 .

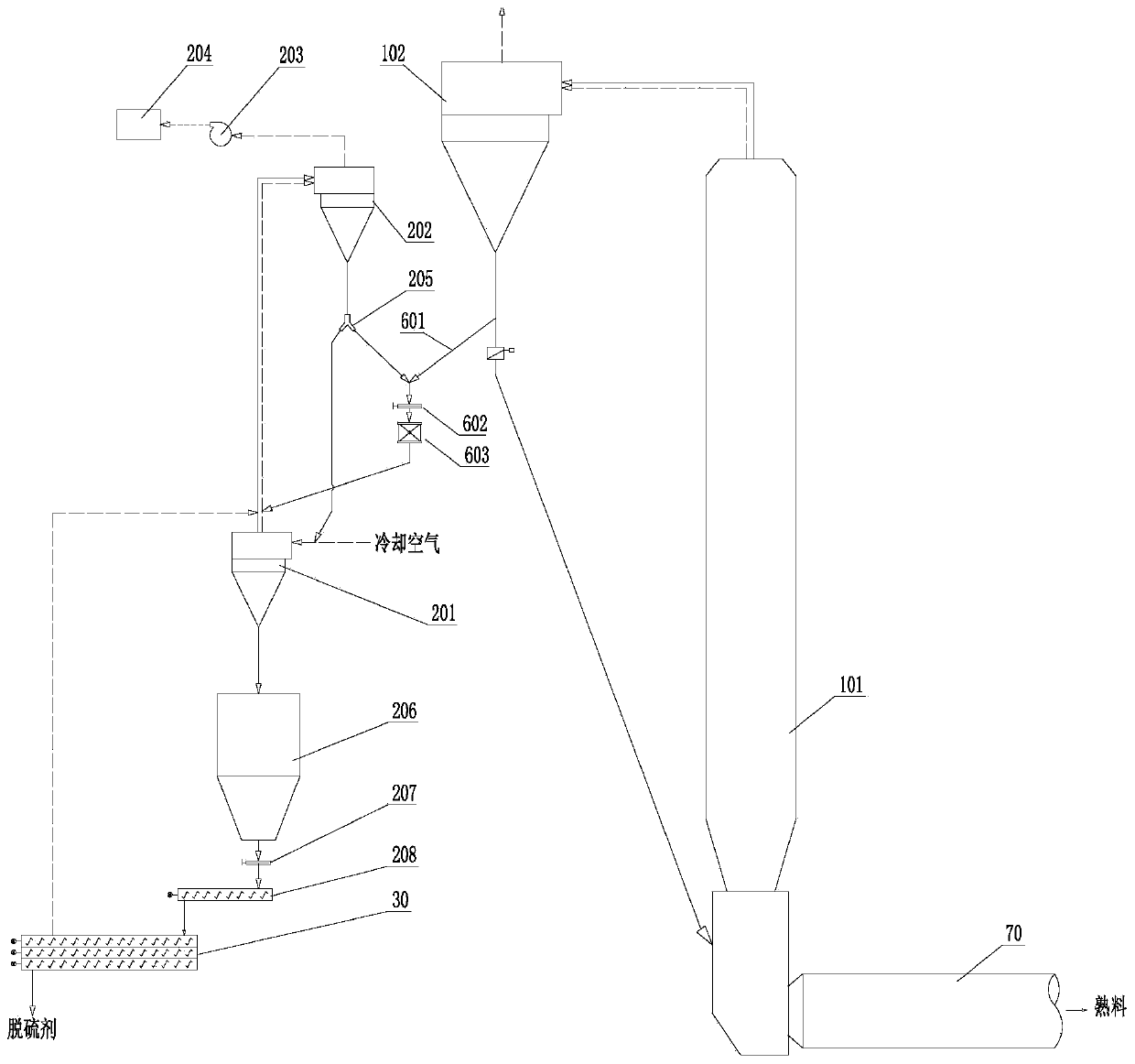

[0119] see Figure 5 and Figure 6 , preferably, the cooling unit 20 is connected to the outlet duct of the decomposition furnace 101 through a reclaimer. Most of the active raw meal out of the calciner enters the cyclone 102 of the final kiln tail preheater along with the flue gas, and the rest enters the cooling unit 20 through the reclaimer for cooling.

[0120] Further preferably, the reclaimer includes a reclaiming cyclone 604, the inlet and outlet ducts of the reclaiming cyclone 604 are provided with high-temperature gate valves 605, 606, and the inlet of the reclaiming cyclone 604 is The pipeline is connected to the outlet duct of the calciner 101, the outlet duct of the reclaiming cyclone 604 is connected to the outlet duct of the final or penultimate kiln tail preheater, and the outlet duct of the reclaiming cyclone 604 is connect...

Embodiment 3

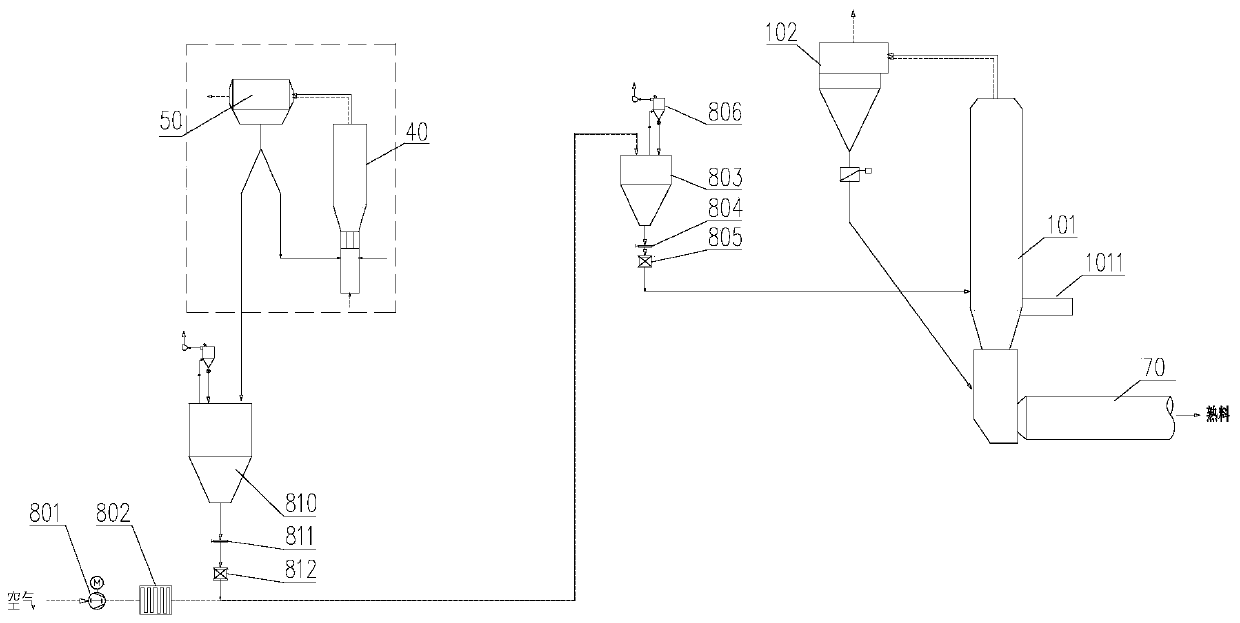

[0124] Different from Embodiment 1 and Embodiment 2, please refer to Figure 7 , the desulfurization unit 40 is also provided with a slaked lime feeding port 405 . When performing equipment maintenance, or system failure, or SO in flue gas 2 When the concentration is relatively high, or the desulfurizer made by the active raw meal cannot meet the desulfurization requirements, the desulfurizer entering the desulfurization unit 40 can be added with a certain amount of slaked lime in addition to the desulfurizer made by the active raw meal, so as to ensure the stable desulfurization work. Efficient desulfurization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com