Method for preparing high-strength aluminum alloy through selective laser melting

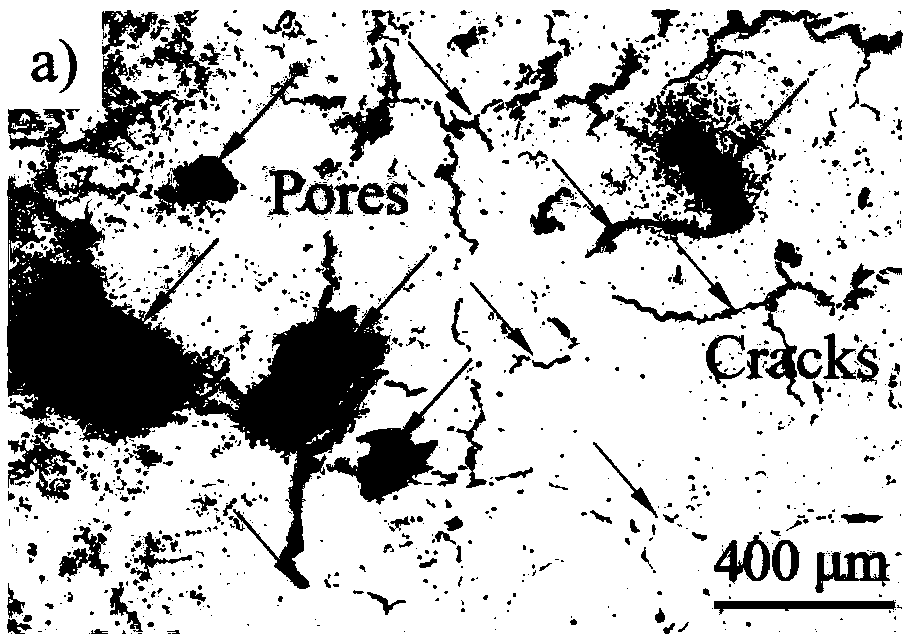

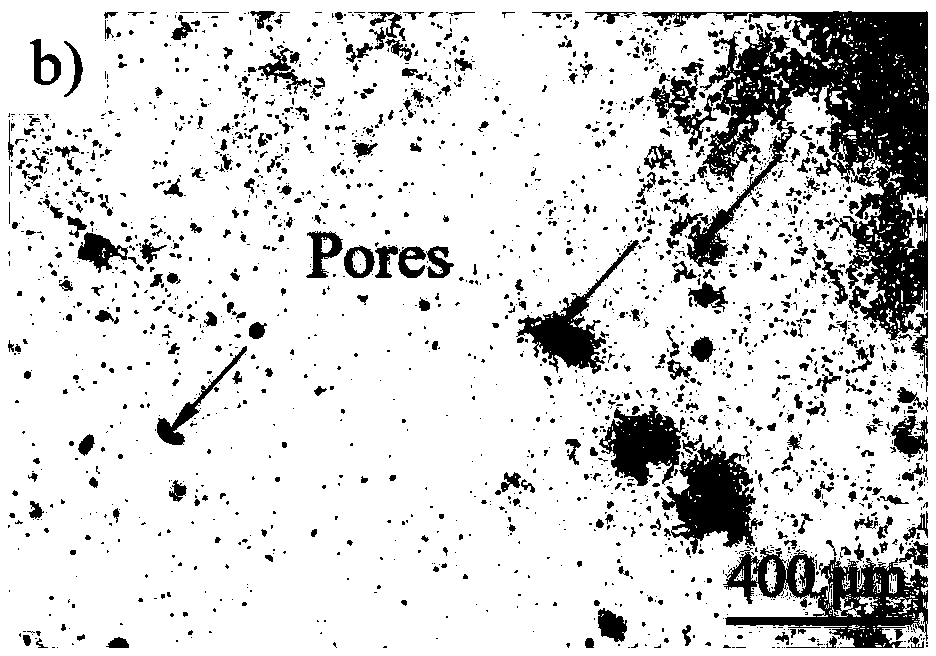

A selective laser melting and aluminum alloy technology, applied in the direction of additive manufacturing, energy efficiency improvement, metal processing equipment, etc., can solve the problems affecting the formability and mechanical properties of alloys, so as to avoid thermal cracks and hole defects, improve mechanical properties, The effect of fine and uniform grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for the selective laser melting forming of Al-Zn-Mg-Cu high-strength aluminum alloy comprises the following steps:

[0046] The material provided is Al-Zn-Mg-Cu high-strength aluminum alloy spherical powder (grain size 200 mesh, D90 is 40μm), and composite particles (40nm hard phase titanium carbide and 40μm alloy element titanium, volume ratio 1:1) Mix according to the weight ratio of 100:2 and put it into the powder cartridge.

[0047] Vacuumize the chamber of selective laser melting equipment to 10 -3 Pa, filled with high-purity argon, repeated 3 times. Spread powder on the powder bed, and preheat the powder-coated substrate to 150°C.

[0048] Selective laser melting process parameters: laser power 210w, laser diameter 80μm, scanning speed 135mm / s, scanning distance 50μm, layer thickness 70μm. After the part is formed, it is cooled slowly in the forming cavity to prevent cracks caused by chilling.

[0049] An Al-Zn-Mg-Cu high-strength aluminum alloy fo...

Embodiment 2

[0053] The method for the selective laser melting forming of Al-Si-Mg-Cu high-strength aluminum alloy comprises the following steps:

[0054] The material provided is Al-Si-Mg-Cu high-strength aluminum alloy spherical powder (grain size 200 mesh, D90 is 40μm), and composite particles (40nm hard phase titanium carbide and 40μm alloy element strontium, volume ratio 1:1) Mix according to the weight ratio of 100:1 and put it into the powder cartridge.

[0055] Vacuumize the chamber of selective laser melting equipment to 10 -3 Pa, filled with high-purity argon, repeated 3 times. Spread powder on the powder bed, and preheat the powder-coated substrate to 150°C.

[0056] Selective laser melting process parameters: laser power 210w, laser diameter 80μm, scanning speed 135mm / s, scanning distance 50μm, layer thickness 70μm. After the part is formed, it is cooled slowly in the forming cavity to prevent cracks caused by chilling.

[0057] An Al-Si-Mg-Cu high-strength aluminum alloy f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com