Photoluminescence material, and preparation method and applications thereof

A technology of reaction solution and compound, applied in the field of photoluminescent materials and their preparation, can solve the problems of difficulty and cost of increasing oxygen content, and achieve the effects of superior performance, low material cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

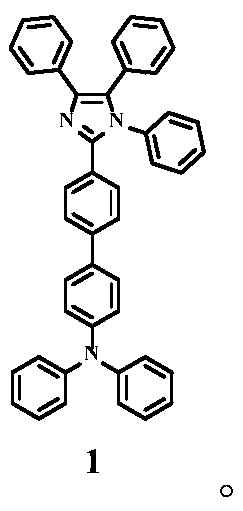

[0030] The synthesis of embodiment 1 intermediate 1a

[0031] Under nitrogen protection, aniline (931mg, 10mmol), benzil (420mg, 2mmol), 4-bromobenzaldehyde (370mg, 2mmol), and ammonium acetate (617mg, 8mmol) were dissolved in acetic acid (20mL) solvent, and the system Reflux for 14 hours. After the system is cooled, add deionized water, a large amount of white solid is precipitated, filter, extract the obtained white solid with dichloromethane and deionized water, combine the organic phase, and add anhydrous MgSO to the obtained organic phase 4 After drying, it was concentrated under reduced pressure, and then separated and purified by column chromatography. The stationary phase was 300-400 mesh silica gel, and the mobile phase was dichloromethane. Finally, 765 mg of the target product was obtained as a white solid with a yield of 85%. 1 H NMR (500MHz, DMSO) δ7.50 (t, J = 7.4Hz, 4H), 7.37–7.22 (m, 14H), 7.19 (t, J = 7.3Hz, 1H). MS (ESI) theoretical value m / z: 451.4, measur...

Embodiment 2

[0032] The synthesis of embodiment 2 compound 1

[0033] Under nitrogen protection, 1a (225mg, 0.5mmol), triphenylamine boronic acid (200mg, 0.54mmol), sodium carbonate (424mg, 4mmol), tetrakistriphenylphosphine palladium (30mg), dissolved in distilled water (2ml) and toluene (3ml) in a mixed solvent, the system was refluxed for 48 hours. After the system was cooled, a small amount of distilled water was added to quench the reaction, the obtained mixed solution was extracted with dichloromethane and deionized water, the organic phases were combined, and anhydrous MgSO was added 4 After drying, it was concentrated under reduced pressure, and then separated and purified by column chromatography. The stationary phase was 300-400 mesh silica gel, and the mobile phase was dichloromethane: petroleum ether = 3:1 mixed solvent. Finally, 369 mg of the target product was obtained as a white solid. The yield was 60%. 1 H NMR (500MHz, DMSO) δ7.58(dd, J=16.2, 8.7Hz, 4H), 7.50(d, J=7.2Hz,...

Embodiment 3

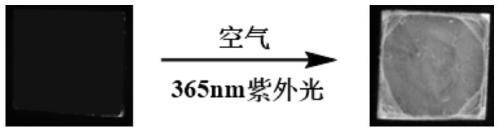

[0034] Embodiment 3 Preparation of compound 1 solid film

[0035] Compound 1 described in Example 1 was configured into a dichloromethane solution, the solution concentration was 5mg / ml, N 2 Under the atmosphere, place a quartz plate on the spin coater, drop 1-3ml of the above solution on the quartz plate, set the spin coating time to 10 seconds, and the speed to 1000 rpm, turn on the switch, and spin coat to form a film.

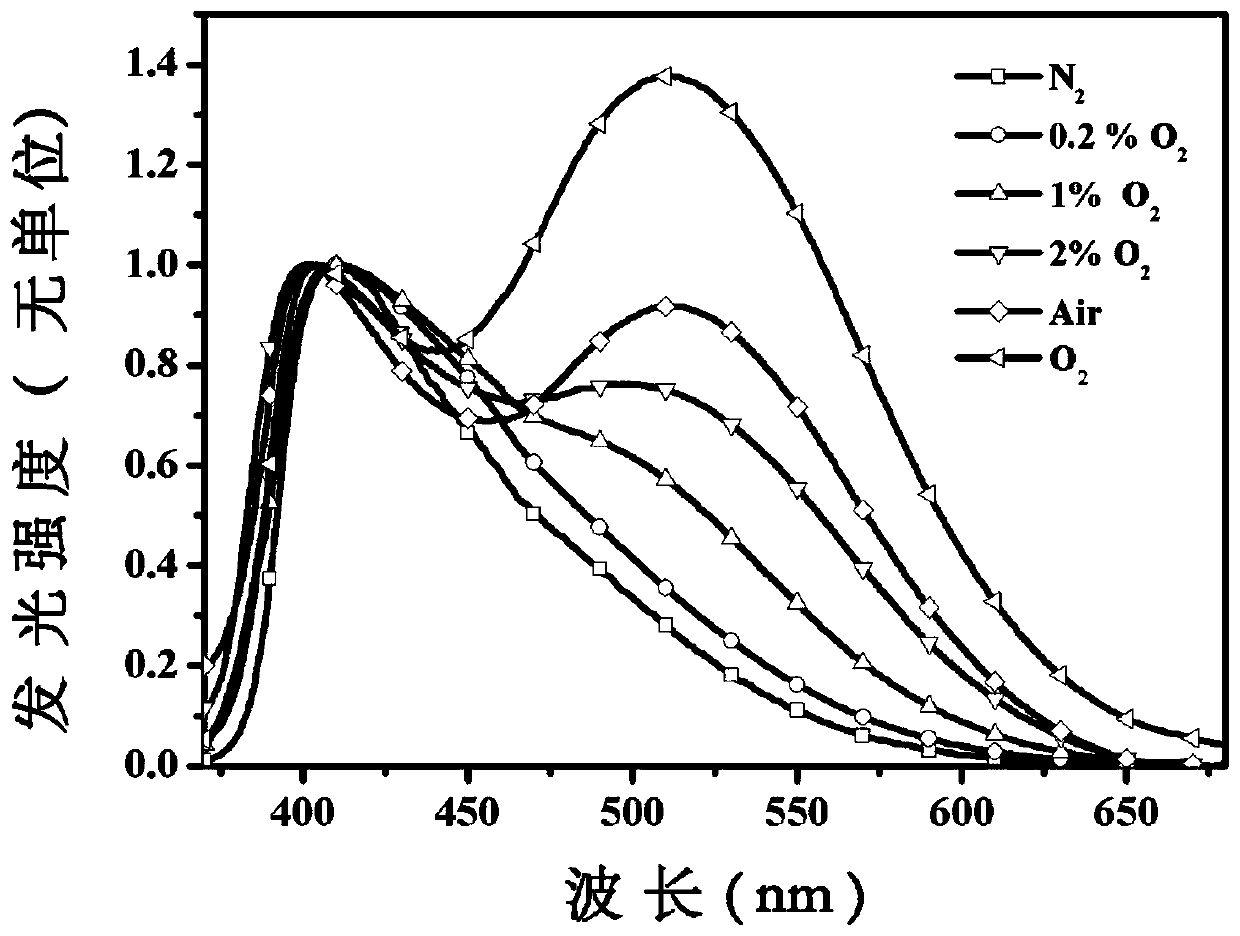

[0036] Such as figure 2 As shown, under the condition of pure nitrogen, the blue light emission peak of the film material itself is at about 410nm, without changing other test conditions, as the oxygen content in the test environment increases, a new yellow fluorescence peak at 520nm appears and It increases with the increase of oxygen content, which means that we can quantitatively judge the oxygen content of the test environment through the intensity of the yellow fluorescent peak in the test, and, as figure 2It is shown that until the oxygen content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com