Method for constructing recombinant bacillus subtilis with high-yield hyaluronic acid oligosaccharide

A technology of hyaluronic acid oligosaccharide and Bacillus subtilis is applied in the field of bioengineering, which can solve the problem of low production intensity and achieve the effects of improving production intensity, increasing yield and reducing the phenomenon of bacterial autolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

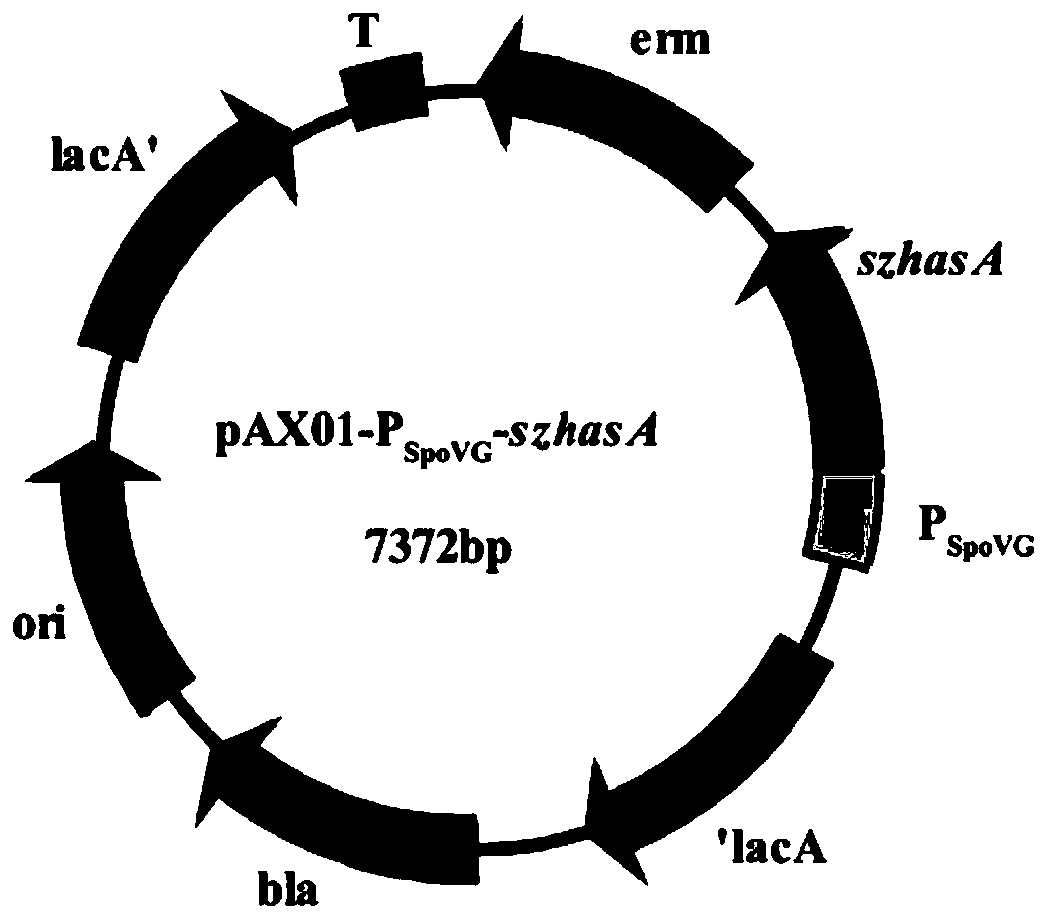

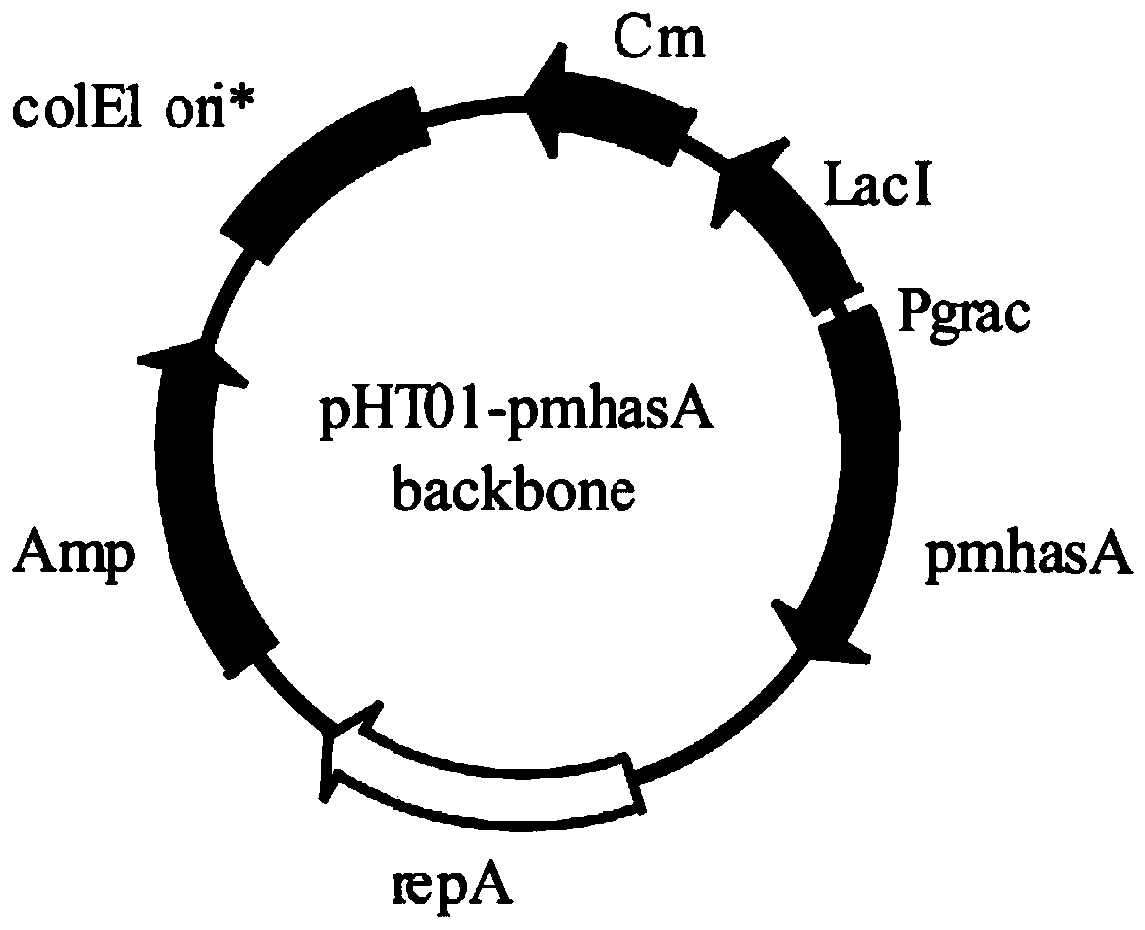

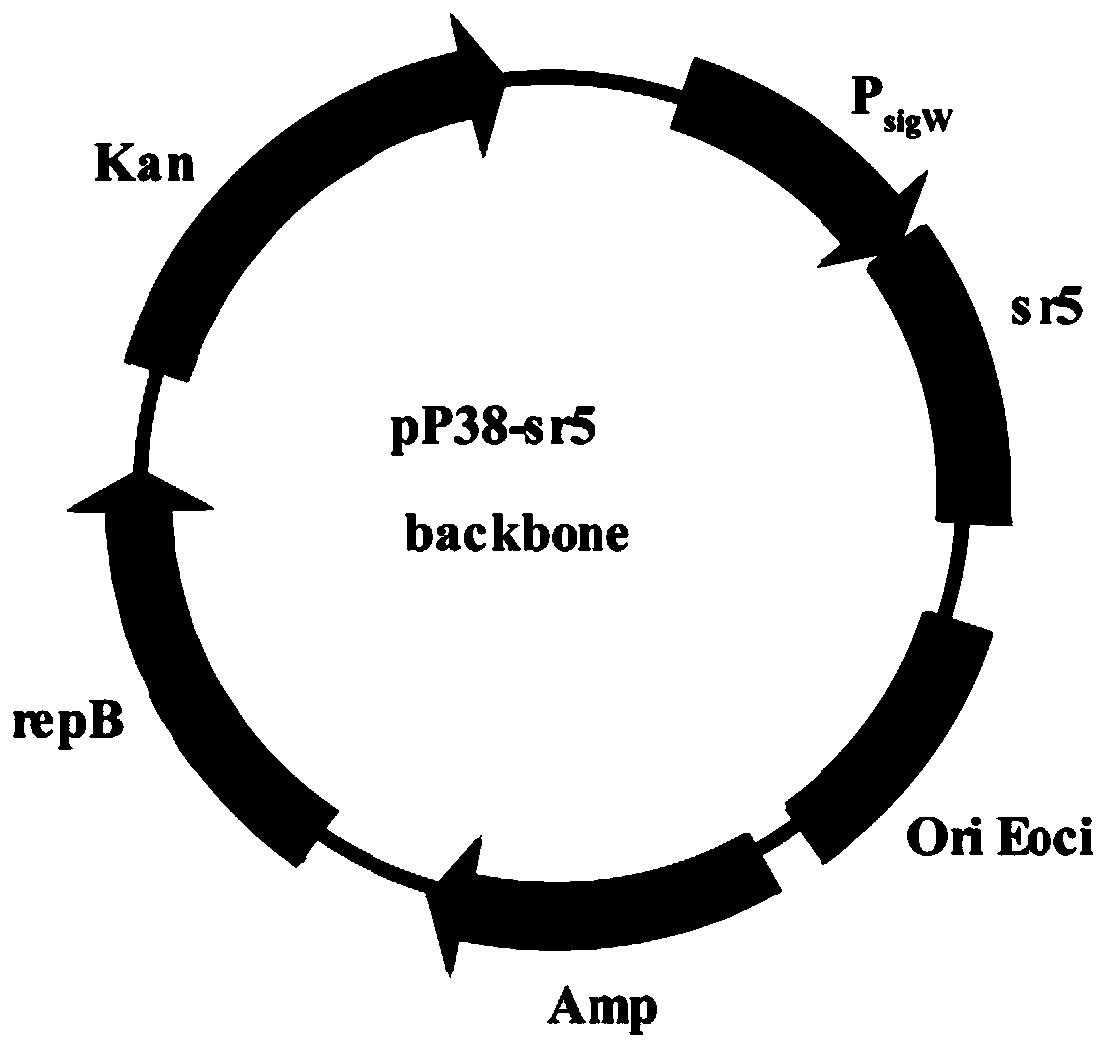

[0043] Embodiment 1 recombinant plasmid and H6Ha sz / pm Construction of / DUMS / sr5 recombinant bacteria

[0044] 1.1 Integration of expression genes glmM, glmS, glmU, tuaD and leech-derived hyaluronan hydrolase gene H6LHyal

[0045] Select yoyJ-yoyA, lytH, lytD, lytG, and lytC in the Bacillus subtilis genome as integration sites, and integrate the pathway genes glmM, glmS, glmU, tuaD and leech-derived hyaluronan hydrolase gene H6LHyal into these sites, respectively, P 43 A promoter is a promoter.

[0046] Taking the integration of the H6LHyal gene into the lytC site of the genome as an example, the integration method is as follows: first, construct a DNA recombinant fragment lytC(shang)-lox71-zeocin-lox66-P containing 5 modules through homologous recombination 43 -H6LHyal[SP(yweA)]--lytC(xia), which respectively include: ①A DNA fragment larger than 500bp upstream of the lytC site on the genome of B. subtilis168 (using primers lytC(shang)-F / lytC(shang)-R from B. subtilis168 g...

Embodiment 2

[0066] Example 2 H6Ha sz / pm Fermentation results of / DUMS / sr5 recombinant bacteria

[0067] 2.1 Culture method

[0068] Seed culture: inoculate the seeds (using LB medium) in the 50ml shaking tube into a 500mL Erlenmeyer flask containing 50mL seed medium, and add kanamycin at a final concentration of 50μg / ml at the beginning of the cultivation, 5μg / ml Erythromycin, 20μg / ml bleomycin, 25μg / ml chloramphenicol and 1.5mmol / L IPTG inducer, cultured at 37°C, 200r / min for 12-16 hours.

[0069] Shake flask fermentation: Transfer the seed culture solution to a 500mL Erlenmeyer flask containing 50mL fermentation medium according to the inoculation amount of 10%, and add the final concentration of 50μg / ml kanamycin, 5μg / ml erythromycin, 20μg / ml ml bleomycin, 25 μg / ml chloramphenicol and 1.5 mmol / L IPTG inducer, cultured at 37°C and 200 r / min for 24 hours.

[0070] Fermentation in 3L fermenter: put the seed solution into a 3L fermenter containing 1.35L fermentation medium according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com