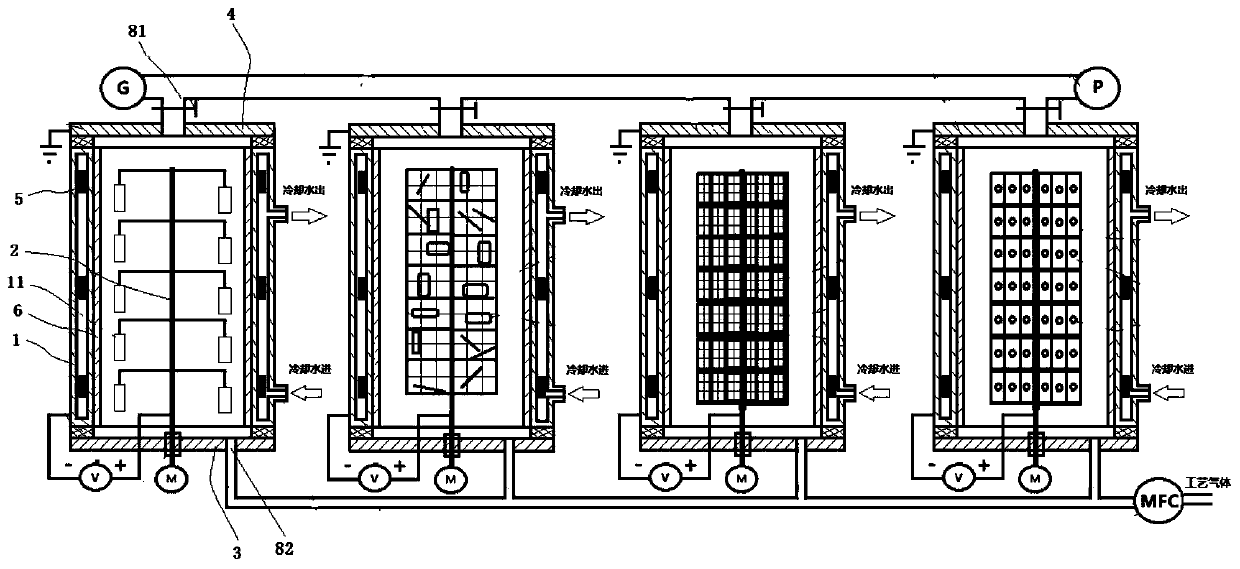

Magnetron sputtering coating system and method for preparing dysprosium / terbium coatings

A magnetron sputtering coating and magnetron sputtering technology, applied in the field of magnetron sputtering, can solve the problems of low deposition rate, expensive and complicated equipment, and low target utilization rate, and achieve high deposition rate and high plasma density , the effect of high target utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Five pieces of commercial N52, N42SH and N50H magnet unit blanks were used as workpieces for terbium plating. The dimensions of the magnet units are 56mm×30mm×4mm and 34mm×33mm×4mm respectively, and the direction of 4mm is the magnetization direction of the magnet unit.

[0061] (2) The magnetic sheet is dried after degreasing, pickling and ultrasonic alcohol cleaning;

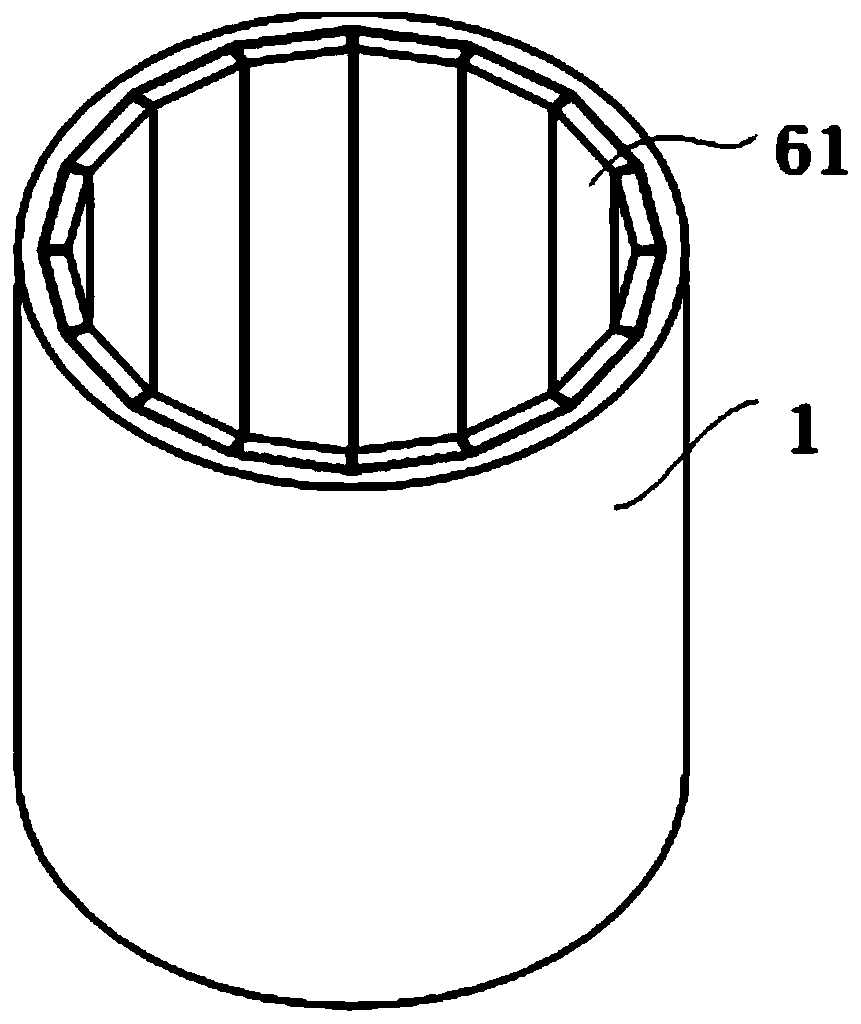

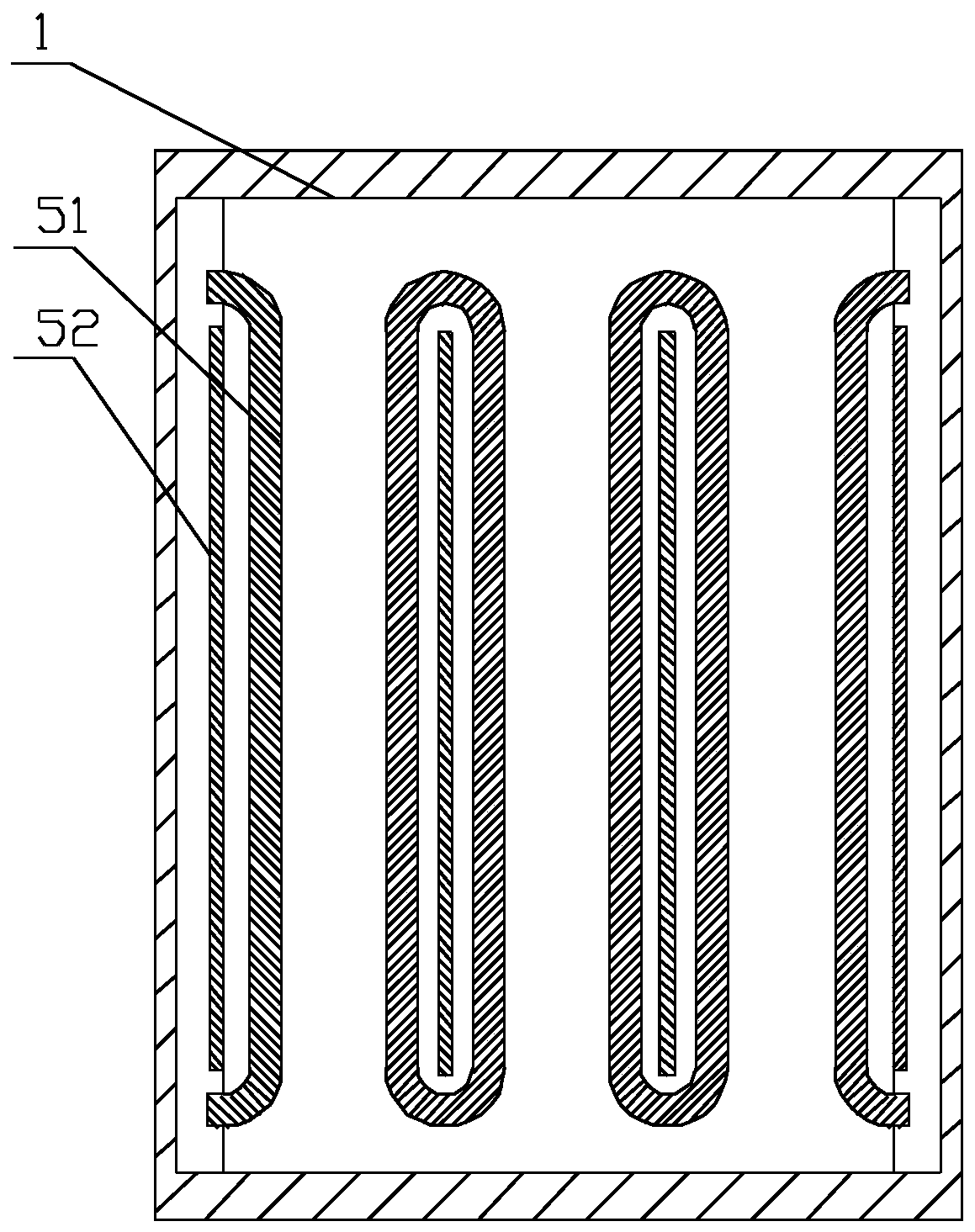

[0062] (3) Install the cleaned magnetic sheet on the workpiece frame and fix it with wire mesh. The tubular magnetron sputtering source used for the coating has a regular hexagonal cross-section with a distance of 260 mm across sides and a length of 420 mm. The sputtering coating adopts terbium metal with a purity of 99.9wt.%. The vertical distance between the magnetic sheet and the target surface is about 20mm;

[0063] (4) Turn on the vacuum pumping system to pump the internal air pressure of the tubular magnetron sputtering source to less than 5×10-3Pa, then introduce the working gas argon int...

Embodiment 2

[0073] (1) Five pieces of commercial N52, N42SH and N50H magnet unit blanks were used as workpieces for terbium plating. The dimensions of the magnet units are 56mm×30mm×4mm and 34mm×33mm×4mm respectively, and the direction of 4mm is the magnetization direction of the magnet unit.

[0074] (2) The magnetic sheet is dried after degreasing, pickling and ultrasonic alcohol cleaning;

[0075](3) Install the cleaned magnetic sheet on the workpiece frame and fix it with wire mesh. The tubular magnetron sputtering source used for the coating has a regular hexagonal cross-section with a distance of 260 mm across sides and a length of 420 mm. Dysprosium metal is used for sputtering coating with a purity of 99.9wt.%. The vertical distance between the magnetic sheet and the target surface is about 20mm;

[0076] (4) Turn on the vacuum pumping system to pump the internal air pressure of the tubular magnetron sputtering source to less than 5×10-3Pa, then introduce the working gas argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com