N type boron carbon nitrogen film/P type single crystal silicon heresy PN native device and preparation method

A boron carbon nitride, pn junction technology, applied in the field of n-type boron carbon nitride film/p-type single crystal silicon hetero pn junction prototype device and preparation, can solve the limitation of boron carbon nitrogen film research and application development, boron carbon nitrogen film The structural uncertainty of nitrogen films and the difficulty of synthesizing boron carbonitride compounds have achieved the effects of easy industrialization, low cost, high breakdown voltage and working voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

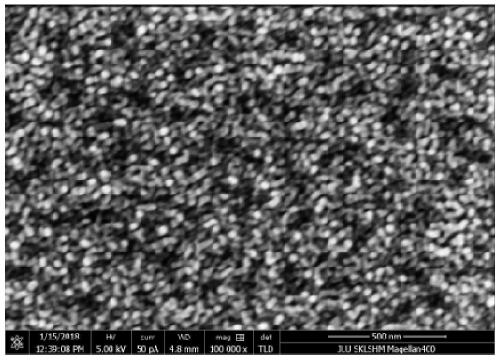

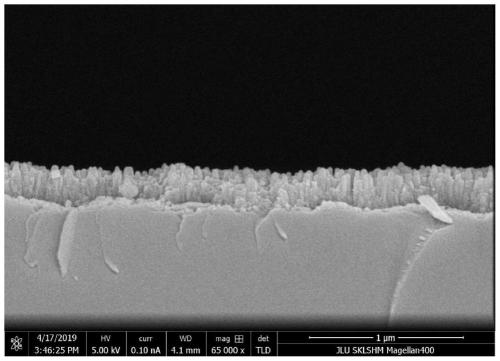

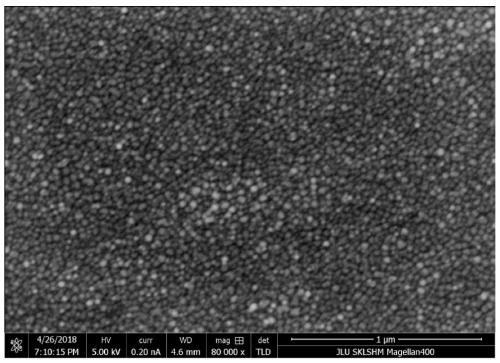

[0029] After the p-type silicon (100) single wafer cut according to the required size is ultrasonically cleaned in acetone, ethanol, and deionized water, it is blown dry with nitrogen and sent to the vacuum deposition chamber. The distance between the substrate and the target is 8cm. The indoor vacuum is pumped to 3×10 - 5 Pa, heat the substrate to 500°C; continue vacuuming until the back vacuum of the deposition chamber reaches 3×10 -5 At Pa, the working gas argon 50sccm is introduced until the working pressure is 2Pa; the base negative bias is applied to -100V, and the target sputtering power is set to 150W to start glowing. After 2 minutes of pre-sputtering, the baffle is removed to perform thin film sputtering. The film sputtering time is 2 hours, and the n-type boron carbon nitrogen film / p-type single crystal silicon heterogeneous pn junction is obtained. Prepare silver electrodes on both sides of the n-type boron carbon nitrogen film / p-type single crystal silicon heter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com