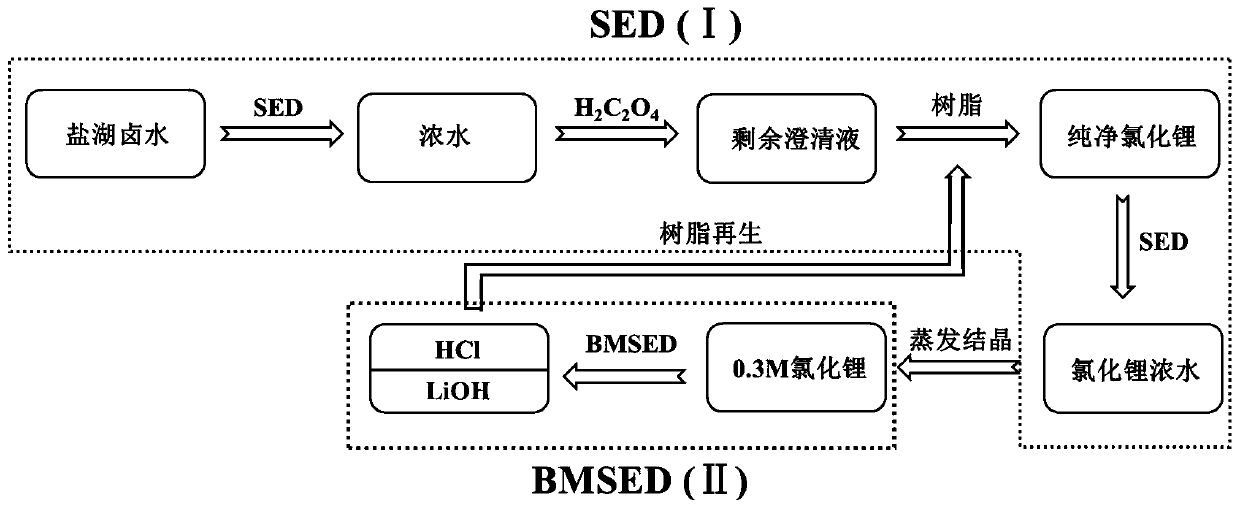

Method of integrating selective electrodialysis and selective bipolar membrane electrodialysis to treat salt lake brine to prepare lithium hydroxide

A technology of bipolar membrane electrodialysis and salt lake brine, applied in the direction of chemical instruments and methods, lithium oxide;/hydroxide, chloride preparation, etc., to achieve low cost, reduce production cost, and reduce calcium and magnesium ion content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

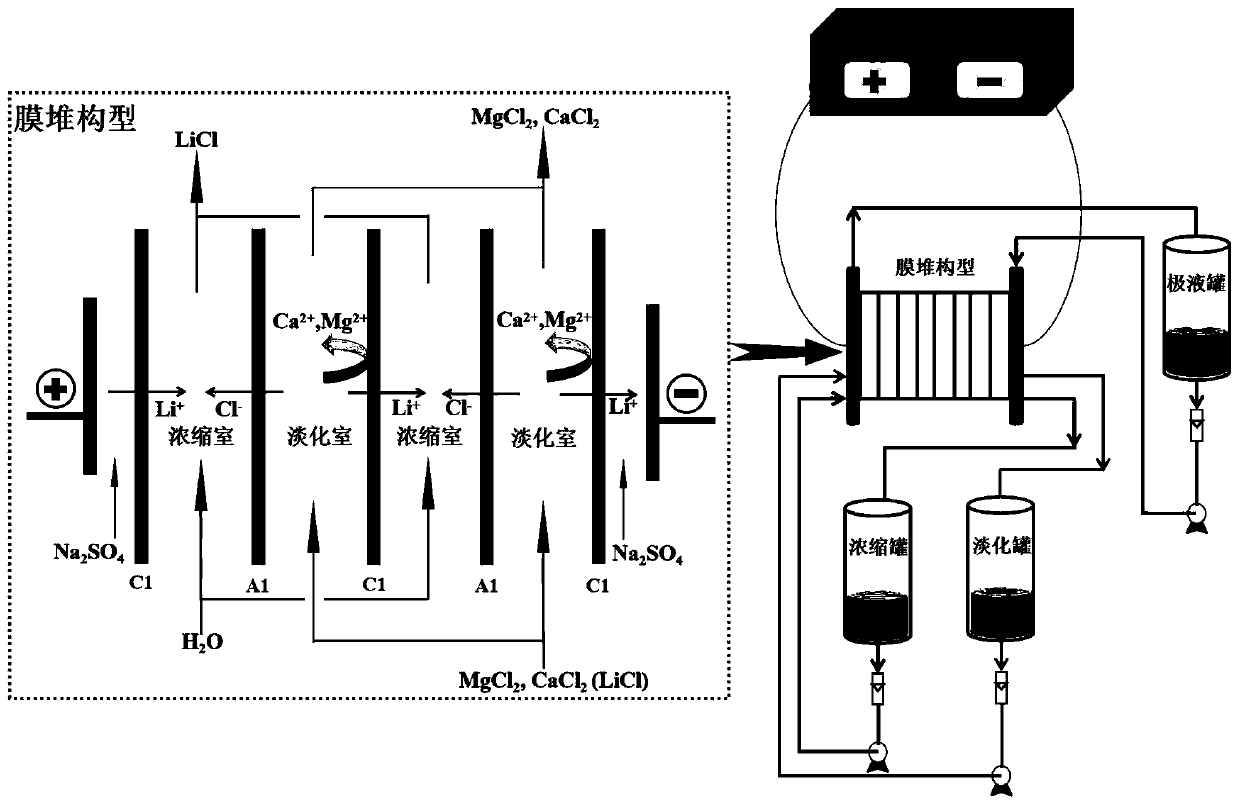

Embodiment 1

[0034] (1) The magnesium ion concentration in the Chaerhan Salt Lake brine used in the present invention is 72500mg / L, the calcium ion concentration is 8910mg / L, and the lithium ion concentration is 159mg / L. The monovalent selective electrodialysis device is attached as figure 2 As shown, the membrane stack is composed of 5 unit electrodialysis cells connected in series, and the assembly sequence of each unit electrodialysis cell from the anode to the cathode is monovalent selective cation exchange membrane, monovalent selective anion exchange membrane, monovalent selective cation exchange membrane, and monovalent selective cation exchange membrane. Membrane to form a concentrating chamber and a desalination chamber, and two adjacent membranes are separated by a separator; the cathode of the monovalent selective electrodialysis device is connected to the negative pole of the DC power supply, and the anode is connected to the positive pole of the DC power supply connected. Th...

Embodiment 2

[0042] With reference to Example 1, step 1) get the film stack that CIMS / ACS / CIMS forms, adjust current density 8,10,12mA / cm 2 Experiment below. It was found that when the current density was 12mA / cm 2 Precipitation occurs in the compartment close to the anode liquid side, which is analyzed to be that the hydroxide ions generated by the electrode solution under high current density leak into the desalination chamber and combine with magnesium ions to produce precipitation. Therefore, it is more reasonable to conduct experiments at low current density.

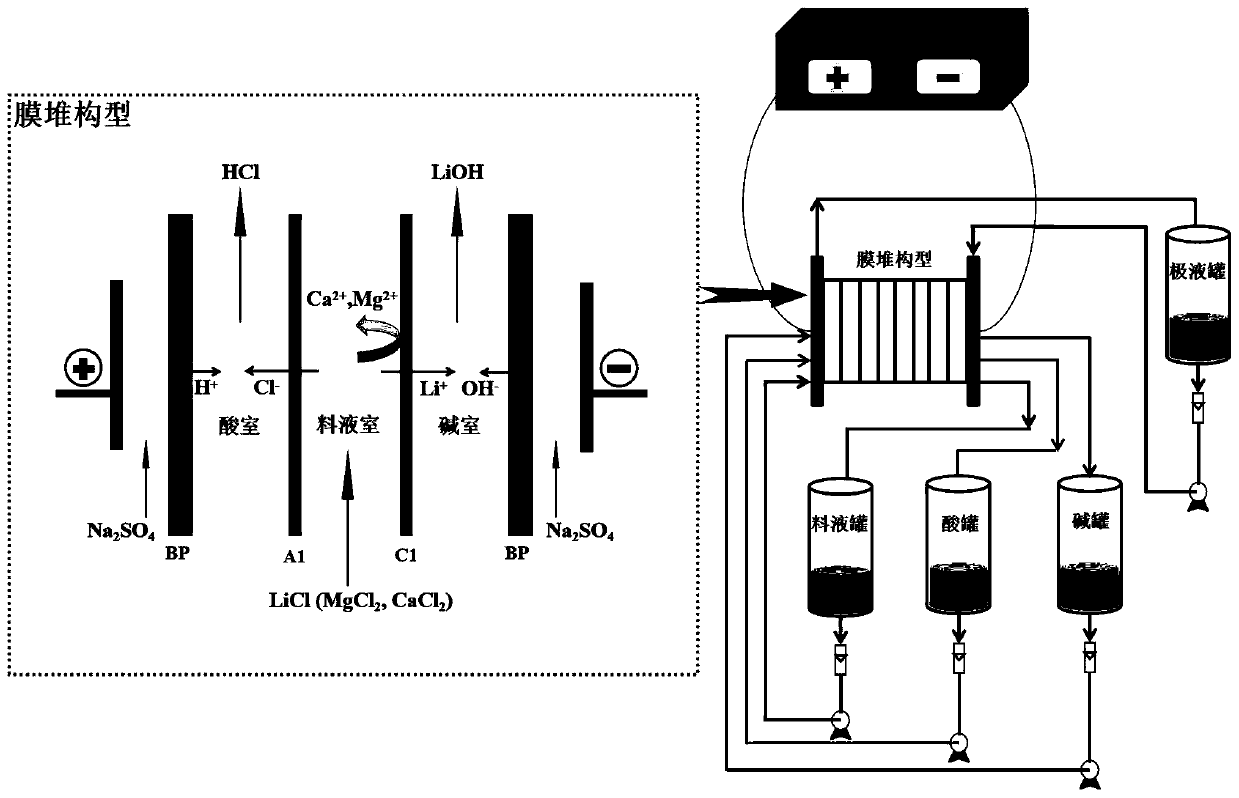

Embodiment 3

[0044] With reference to embodiment 1, step 1) take the membrane stack that CIMS / ACS / CIMS forms to carry out experiment, adjust current density to be 4mA / cm 2 , reacted for 90 minutes, and the lithium ion yield in the concentration chamber was 65.28%.

[0045] Other steps are with embodiment 1, the alkali chamber of final monovalent selective bipolar membrane electrodialysis device obtains lithium hydroxide, detection concentration is 0.161mol / L, and purity is more than 99%, and acid chamber obtains the hydrogen chloride solution of 0.158mol / L, The current efficiency is 53.77%, and the energy consumption is 5.72kWh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com