Colorful coating glass capable of enhancing cooling performance of solar photovoltaic assembly and preparation method

A technology of solar photovoltaic and heat dissipation performance, applied in the direction of coating, can solve the problem of no specific and effective measures for heat dissipation of the backplane of photovoltaic modules, and achieve the effect of simple preparation method and enhanced heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

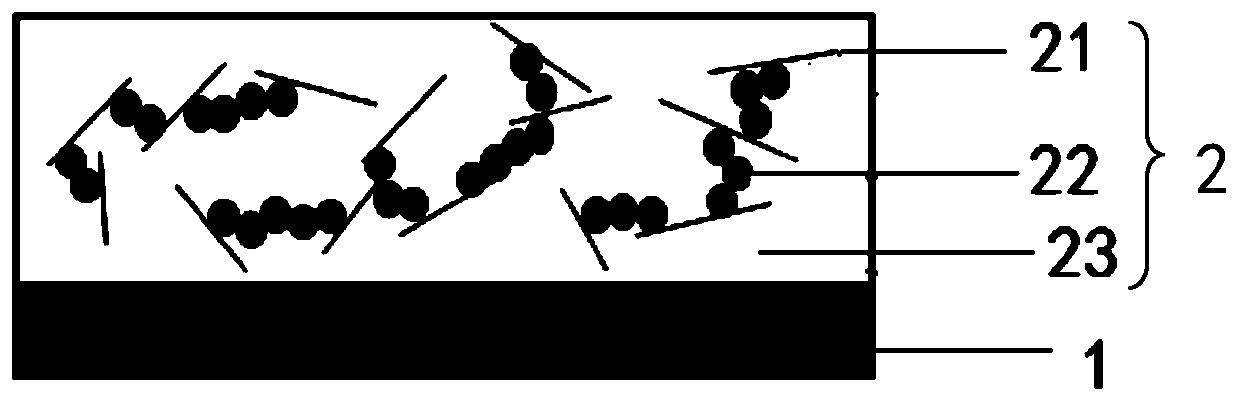

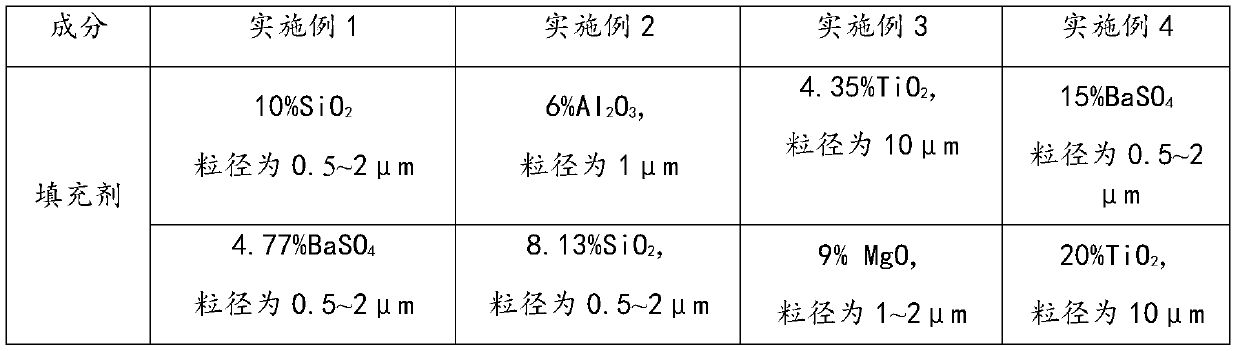

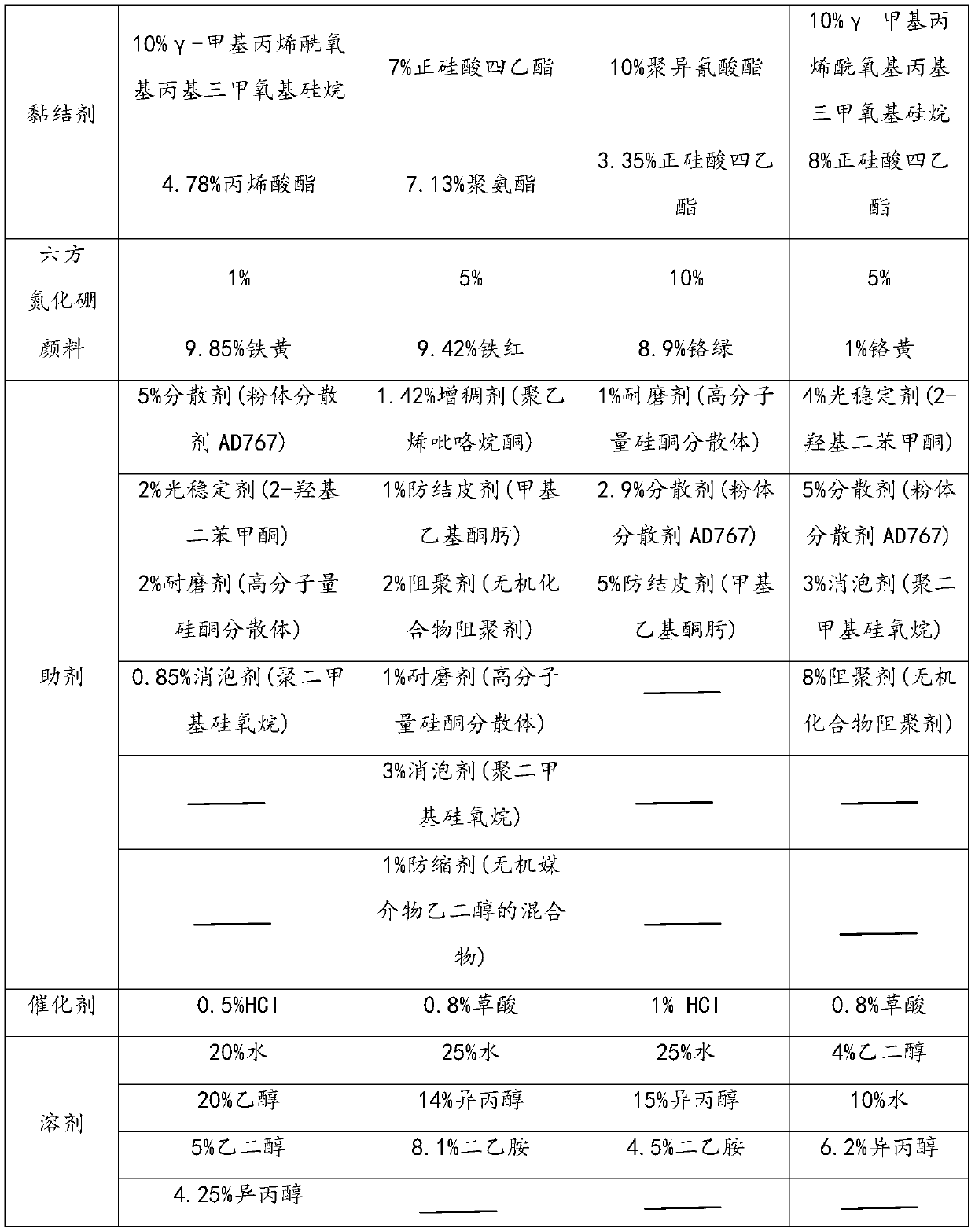

[0027] The color-coated glass for enhancing the heat dissipation performance of solar photovoltaic modules in Examples 1-4 includes a glass substrate and a color coating film arranged on the glass substrate, the thickness of the color coating film is 0.2-200 μm, wherein the color coating film The composition of the main raw materials is shown in Table 1.

[0028] The main raw material composition (mass fraction %) of the color coating film in embodiment 1-4

[0029]

[0030]

Embodiment 1

[0031] The colored coated glass of enhancing the heat dissipation performance of solar photovoltaic modules in embodiment 1 comprises the following steps:

[0032] 1) Add 10% SiO 2 , 4.77% BaSO 4 , 10% γ-methacryloxypropyl trimethoxysilane, 4.78% acrylate, 5% dispersant (powder dispersant AD767), 2% light stabilizer (2-hydroxybenzophenone), 2% Anti-Abrasion Agent (High Molecular Weight Silicone Dispersion), 0.85% Antifoam Agent (Dimethicone), 20% Ethanol, 20% Water, 5% Ethylene Glycol, 4.25% Isopropanol After mixing, stir at 30°C for 6 hours, then add 0.5% HCl and continue stirring for 16 hours, then add 1% hexagonal boron nitride, stir and oscillate evenly at high speed to obtain a color coating material;

[0033] 2) The color coating film material in step 1) is screen-printed on the glass substrate by screen printing, and then dried at 180° C. for 15 minutes. The colored coated glass that this embodiment makes to enhance the heat dissipation performance of solar photovolt...

Embodiment 2

[0034] The colored coated glass of enhancing the heat dissipation performance of solar photovoltaic modules in embodiment 2 comprises the following steps:

[0035] 1) Add 6% Al 2 o 3 , 8.13% SiO 2 , 7% tetraethyl orthosilicate, 7.13% polyurethane, 9.42% iron red, 1.42% thickener (polyvinylpyrrolidone), 1% anti-skinning agent (methyl ethyl ketone oxime), 2% polymerization inhibitor (inorganic compound inhibitor), 1% anti-wear agent (high molecular weight silicone dispersion), 3% defoamer (polydimethylsiloxane), 1% anti-shrinkage agent (inorganic vehicle ethylene glycol) mixture), 25% water, 8.1% diethylamine, and 14% isopropanol were mixed and stirred at 25°C for 8 hours, then added 0.8% oxalic acid and continued to stir for 14 hours, then added 5% hexagonal boron nitride and stirred at a high speed Uniform, get color coating material;

[0036] 2) The color coating film material in step 1) is screen-printed on the glass substrate by screen printing, and then dried at 200° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com