Epoxy resin composition, preparing method and application thereof and aluminum base copper-clad plate

A technology of epoxy resin and solid epoxy resin, applied in epoxy resin glue, chemical instruments and methods, adhesive types, etc., can solve the problems of poor heat resistance and poor heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102] (1) The preparation method of epoxy resin glue:

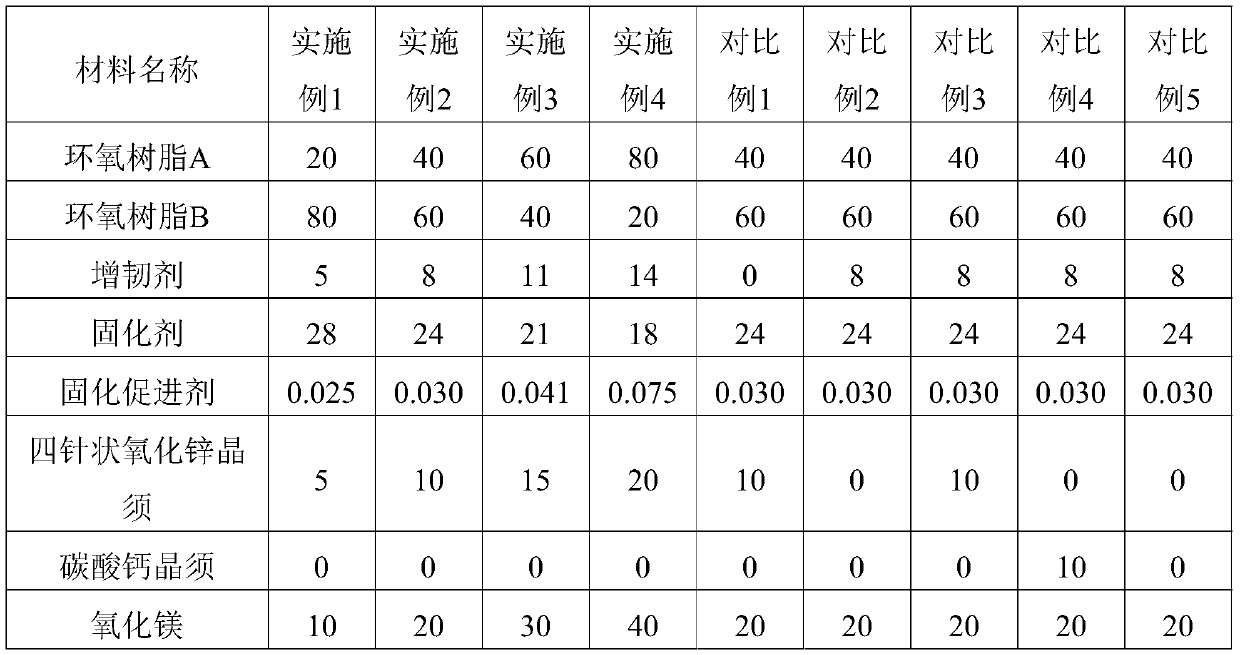

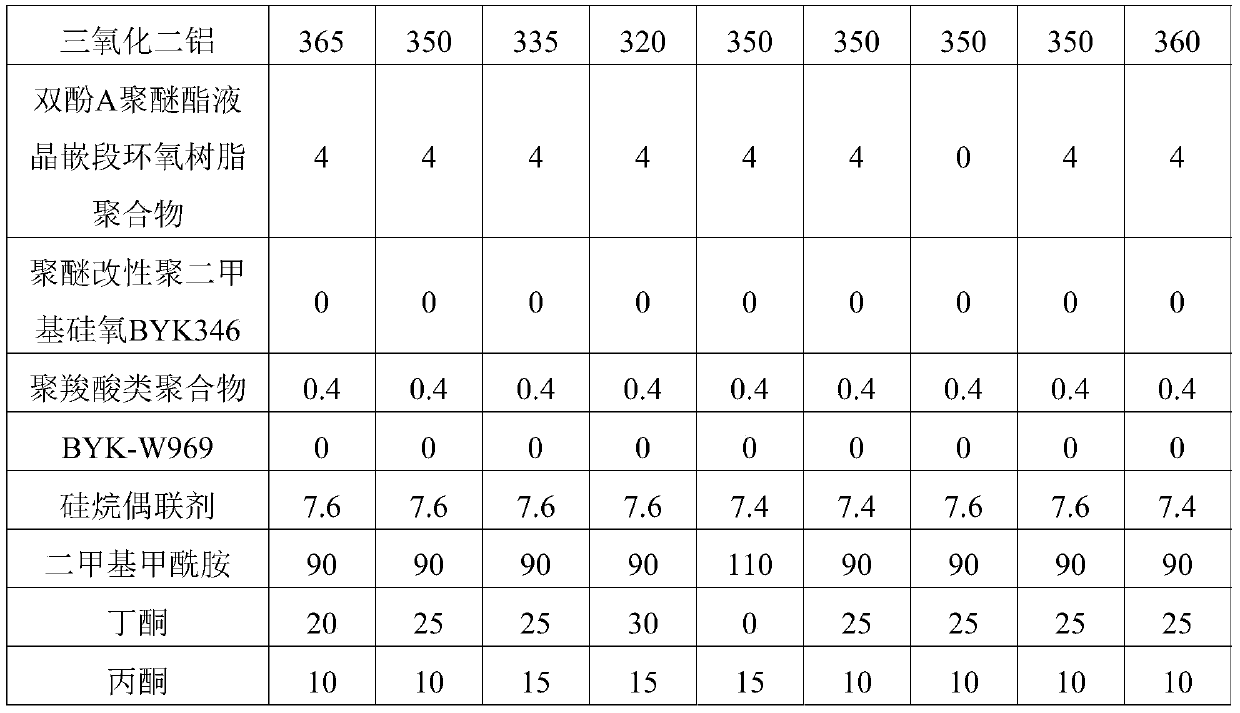

[0103] Mix the ratio of raw materials shown in Table 1-1 and Table 1-2 as follows:

[0104] ①Add dimethylformamide, methyl ethyl ketone, and acetone into the dissolution kettle, add diaminodiphenyl sulfone under stirring, and stir for about 30-60 minutes until the solution is uniform and transparent;

[0105] ② Add other raw materials to the solution in ① according to the mass ratio shown in Table 1, and mix them with a high-shear mixer emulsifier at a speed of 5000 rpm for 5-10 minutes to prepare epoxy resin glue.

[0106] The epoxy resin glue system prepared in Examples 1-4 is uniformly dispersed without agglomeration and settlement.

[0107] (2) Preparation method of double-sided aluminum-based copper clad laminate:

[0108] ① Preparation of glue-coated copper foil: Take the epoxy resin glue prepared in Examples 1-4 and Comparative Examples 1-13, and evenly coat the rough surface of the electrolytic copper foil, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com