Method for manufacturing crumpled graphene composite, composite manufactured thereby, and supercapacitor including composite

A technology of graphene and composites, which is applied in the direction of hybrid capacitor electrodes, hybrid capacitor separators, hybrid capacitor electrolytes, etc., can solve the problems of difficult penetration of electrolytes, achieve good conductivity, low interface resistance, and increase interplanetary spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

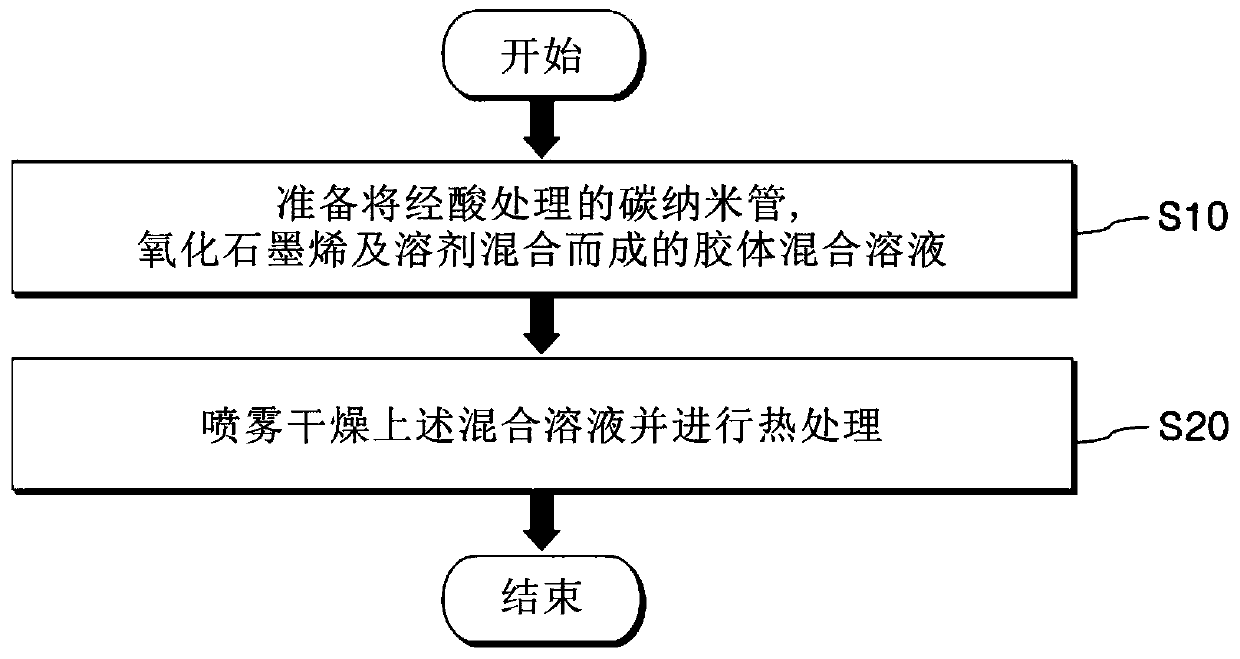

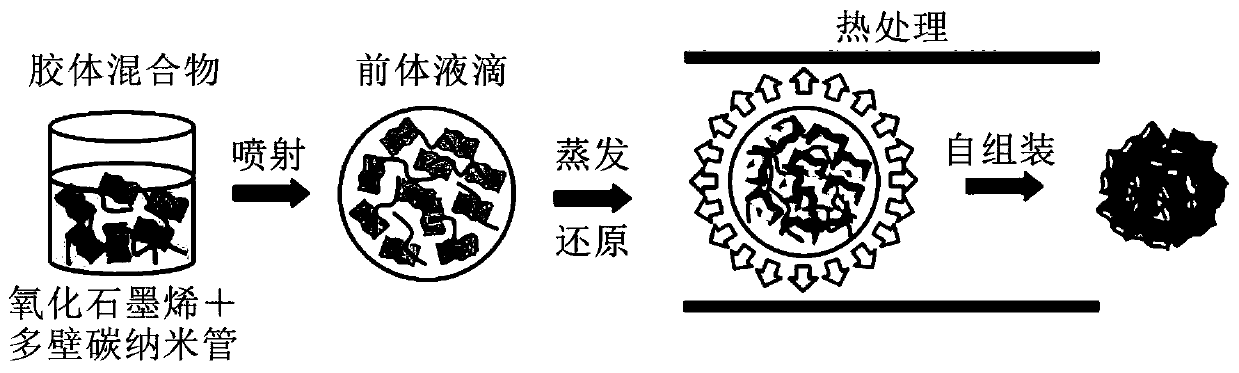

[0077] The first embodiment of the present invention provides a method for preparing a wrinkled graphene-carbon nanotube composite body, comprising: preparing a colloid mixed solution formed by mixing acid-treated carbon nanotubes, graphene oxide and a solvent (step 1) (S10); and spray drying the above mixed solution, and performing heat treatment (step 2) (S20).

[0078] In the existing research on graphene-carbon nanotube composites, there is a problem that the electrolyte is difficult to penetrate into the electrodes of the composites as the re-lamination and condensation phenomena have been occurring between the two-dimensionally structured graphene sheets. Moreover, due to the van der Waals attraction between carbon nanotubes, the aggregation phenomenon occurs between carbon nanotubes, so that the specific capacitance tends to decrease with the increase of current density.

[0079] In order to solve the problem of relamination and aggregation of two-dimensional graphene a...

Embodiment 1

[0194] Preparation 1 of wrinkled graphene-carbon nanotube composite

[0195] Graphene oxide (GO), used as a raw material for preparing graphene, was prepared by dispersing in distilled water after being prepared from graphite according to a modified HumMer's method (HumMer's method).

[0196] Step 1: In order to improve the dispersibility of multi-walled carbon nanotubes (95% purity, NANOLAB) to water, acid treatment was performed. Disperse 1 g of multi-walled carbon nanotubes in 150 mL of sulfuric acid (H 2 SO 4 , 99.5%) and 50mL of nitric acid (HNO 3 ) into the mixed solution, and stirred at a temperature of 70° C. for 2 hours. Subsequently, it was washed by filtration with 5% hydrochloric acid (HCl) solution and dried in air. A mixed solution was prepared with the acid-treated multi-walled carbon nanotubes and graphene oxide at a weight ratio of 0.01:1 and distilled water as a solvent. At this time, the graphene oxide concentration of the mixed solution was 0.25% by...

Embodiment 2

[0199] Preparation 2 of wrinkled graphene-carbon nanotube composite (multi-walled carbon nanotube: graphene oxide weight The amount ratio is 0.05:1)

[0200] In step 1 of the above example 1, except that the weight ratio of multi-walled carbon nanotubes: graphene oxide was changed to 0.05:1 to prepare the mixed solution, the wrinkled graphene was prepared in the same manner as in the above example 1 - Multi-walled carbon nanotube composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle | aaaaa | aaaaa |

| Face distance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com