Lead-free BaTiO3-PVDF (polyvinylidene fluoride) composite membrane and preparation method thereof

A composite film and twinning technology, applied in chemical instruments and methods, film, film technology, etc., can solve the problems of low piezoelectric coefficient, lead content, environmental pollution, etc., and achieve dielectric and ferroelectric performance enhancement, dielectric and the effect of ferroelectric performance improvement and electromechanical coupling performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

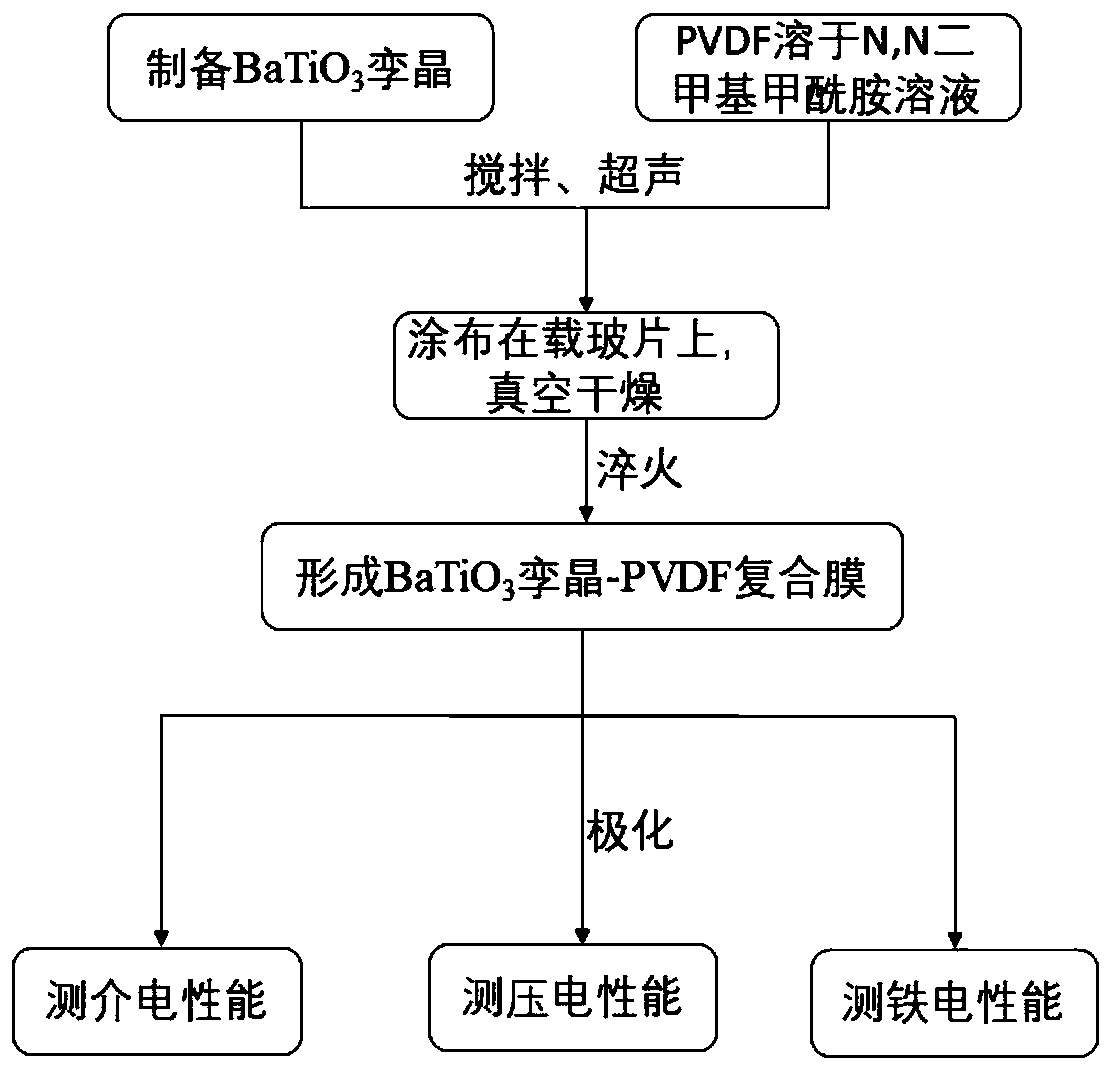

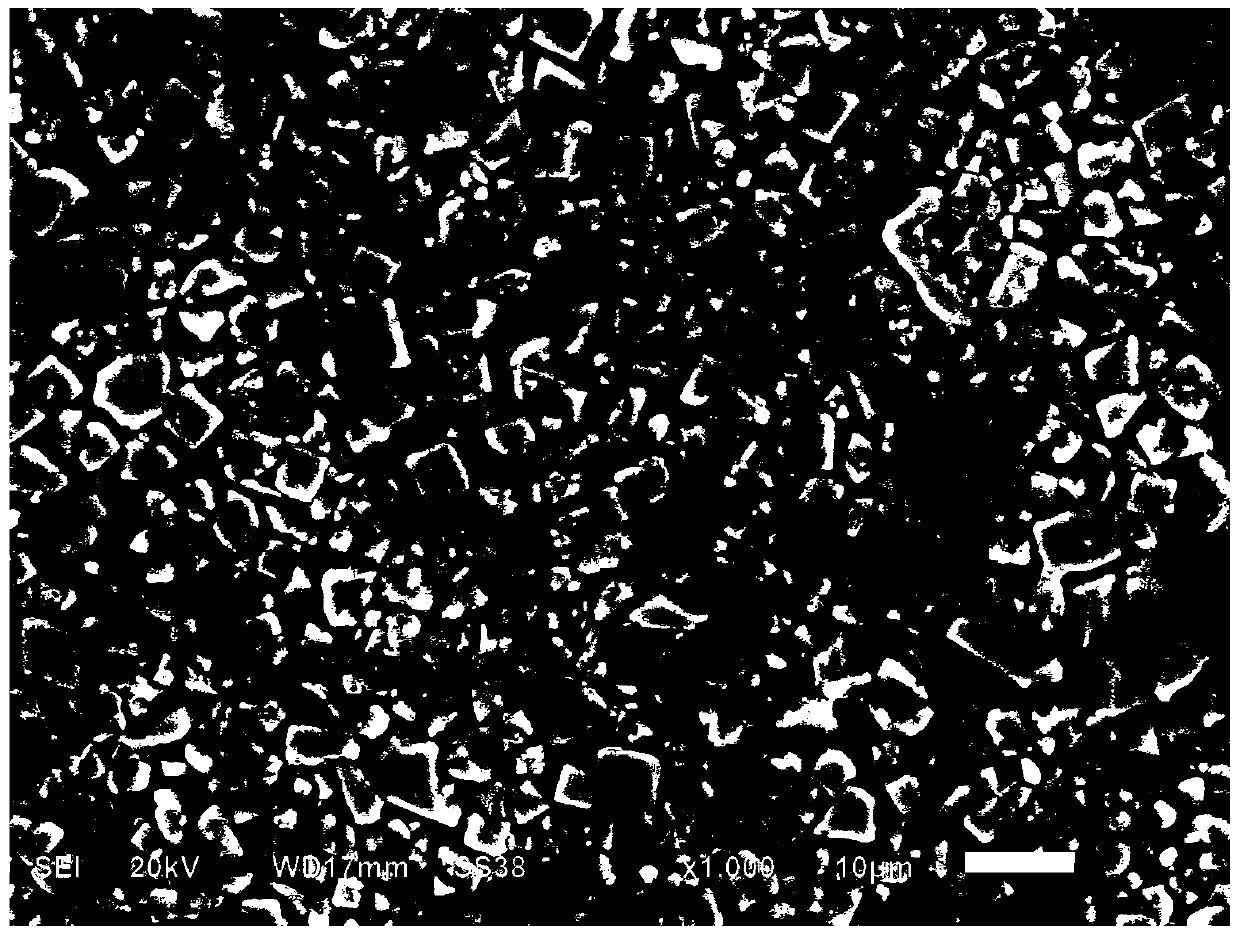

[0051] In this example, a lead-free BaTiO 3 -PVDF composite film, the doping mass fraction of setting composite film is 20%, comprises the following steps:

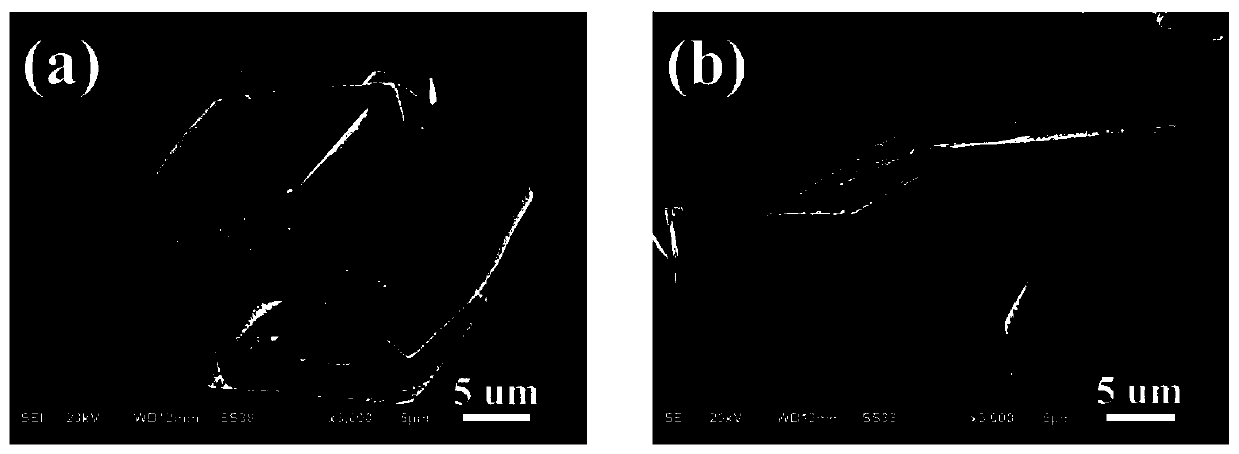

[0052] (1) BaTiO was prepared by alkali-thermal method 3 Twin powder, specifically comprises the following steps:

[0053] A, take by weighing anatase titanium dioxide powder 0.039g, sodium hydroxide 3.877g, potassium hydroxide 5.122g, mix together and put into the reactor;

[0054] b. Put the reaction kettle into the muffle furnace, keep it warm at 180°C for 300min, and cool it naturally;

[0055] c. Take out the reaction kettle, add dropwise 2ml of BaCl with a concentration of 0.3mol / L into the reaction kettle 2 solution;

[0056] d. Put the reaction kettle into the muffle furnace, keep it warm at 180°C for 2880min, and cool it naturally;

[0057] e. Take out the reaction kettle, pour the powder in the reaction kettle into a beaker, add an appropriate amount of deionized water to the beaker, stir for 5 minutes, let...

Embodiment 2

[0073] In this example, a lead-free BaTiO 3 -PVDF composite film, the doping mass fraction of setting composite film is 30%, comprises the following steps:

[0074] (1) BaTiO was prepared by alkali-thermal method 3 Twin powder, specifically comprises the following steps:

[0075] A, take by weighing anatase titanium dioxide powder 0.039g, sodium hydroxide 3.877g, potassium hydroxide 5.122g, mix together and put into the reactor;

[0076] b. Put the reaction kettle into the muffle furnace, keep it warm at 180°C for 300min, and cool it naturally;

[0077] c. Take out the reaction kettle, add dropwise 2ml of BaCl with a concentration of 0.3mol / L into the reaction kettle 2 solution;

[0078] d. Put the reaction kettle into the muffle furnace, keep it warm at 180°C for 2880min, and cool it naturally;

[0079] e. Take out the reaction kettle, pour the powder in the reaction kettle into a beaker, add an appropriate amount of deionized water to the beaker, stir for 5 minutes, let...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com