Preparation method and application of antibacterial active food packaging film

A technology of food packaging film and antibacterial activity, applied in the field of edible film, can solve the problems of improper packaging method, poor antibacterial effect, excessive residual amount of benzene solvents, etc., and achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

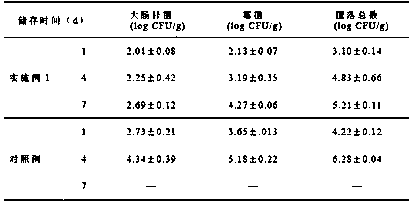

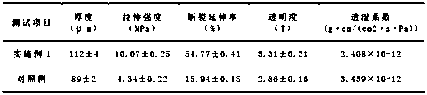

experiment example 1

[0032] This example provides an edible packaging film containing β-cyclodextrin supramolecular natural slow-release bacteriostatic agent for preservation of fruit skin.

[0033] Preparation of β-cyclodextrin and perilla essential oil solution: Take an appropriate amount of β-cyclodextrin powder and dissolve it in deionized water to prepare a 2% (weight percentage, the same below) β-cyclodextrin solution. Perilla essential oil was dissolved in ethanol to prepare a 25% (w / v) solution of perilla essential oil according to the mass ratio of core wall material 1:8.

[0034] Embedding: Mix cyclodextrin solution and perilla essential oil solution at a volume ratio of 90:1, seal the vessel, and stir magnetically at 200 rpm for 4 h at 50 °C.

[0035] Dry the sample: filter the embedding reaction solution first to remove excess cyclodextrin, freeze the filtrate at -20°C for 24 h, then freeze-dry for 48 h, and store in a cool place after freeze-drying.

[0036] Preheating of starch disp...

Embodiment 2

[0042] This example provides a composite packaging film containing hydroxypropyl-β-cyclodextrin supramolecular natural slow-release antibacterial agent for fresh-keeping pork jerky.

[0043] Preparation of hydroxypropyl-β-cyclodextrin and perilla essential oil solution: take an appropriate amount of hydroxypropyl-β-cyclodextrin powder and dissolve it in deionized water to prepare 6% (weight percentage, the same below) hydroxypropyl - Beta-cyclodextrin solution. Perilla essential oil was dissolved in ethanol to prepare 60% perilla essential oil solution (w / v) according to the mass ratio of core wall material 1:10.

[0044] Embedding: Mix cyclodextrin solution and perilla essential oil solution at a volume ratio of 90:1, seal the vessel, and stir magnetically at 200 rpm for 4 h at 50 °C.

[0045] Dry the sample: filter the embedding reaction solution first to remove excess cyclodextrin, freeze the filtrate at -25 °C for 30 h, then freeze-dry for 48 h, and store in a cool place ...

Embodiment 3

[0052] This example provides a composite packaging film containing hydroxypropyl-β-cyclodextrin supramolecular natural slow-release antibacterial agent for keeping bread fresh.

[0053] Preparation of hydroxypropyl-β-cyclodextrin and perilla essential oil solution: take an appropriate amount of hydroxypropyl-β-cyclodextrin powder and dissolve it in deionized water to prepare 5% (weight percentage, the same below) hydroxypropyl - Beta-cyclodextrin solution. Perilla essential oil was dissolved in ethanol to prepare 55% perilla essential oil solution (w / v) according to the mass ratio of core wall material 1:9.

[0054] Embedding: Mix cyclodextrin solution and perilla essential oil solution at a volume ratio of 100:1, seal the vessel, and stir magnetically at 200 rpm for 4 h at 50 °C.

[0055] Dry the sample: filter the embedding reaction solution first to remove excess cyclodextrin, freeze the filtrate at -20 °C for 48 h, then freeze-dry for 48 h, and store in a cool place after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com