Functional diaphragm for lithium-ion batteries and preparation method and application thereof

A lithium-ion battery, functional technology, applied in the field of functional diaphragms for lithium-ion batteries and its preparation, can solve problems affecting cycle performance, metal cation dissolution, etc., achieve good oxidation resistance and thermal stability, and reduce aging , Improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

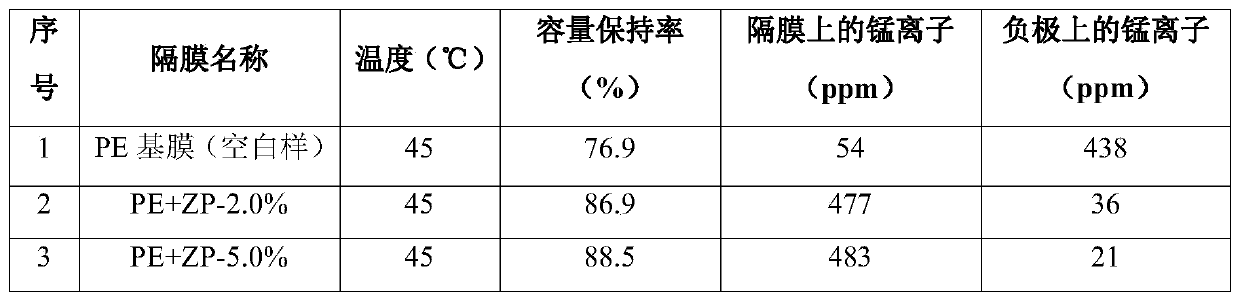

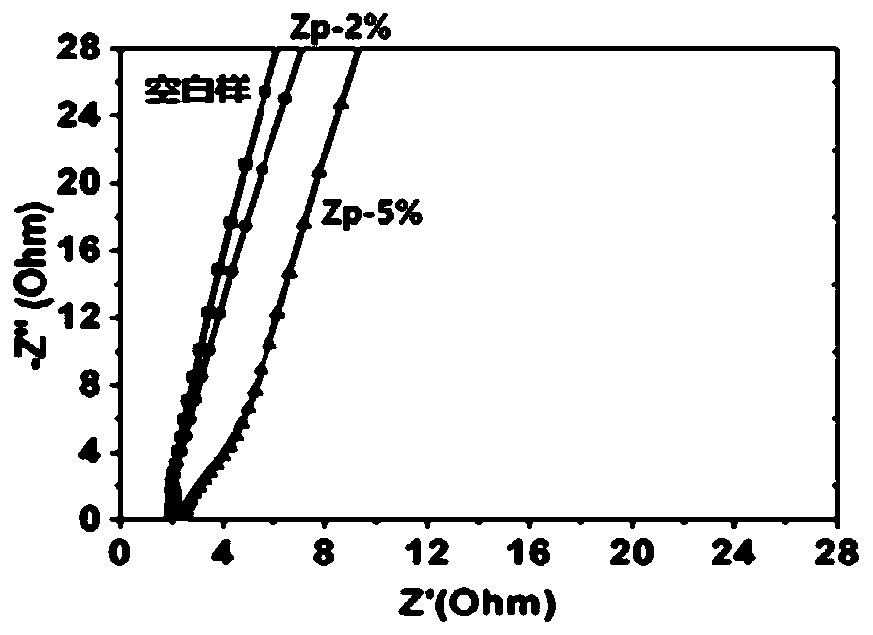

Embodiment 1

[0044] A functional separator for a lithium ion battery in this embodiment includes a polyethylene separator base material and a zirconium hydrogen phosphate functional material, wherein the added amount of zirconium hydrogen phosphate is 2% of the total amount of the polyethylene separator base material. The functional separator is prepared by a wet process. Specifically, polyethylene raw materials, zirconium hydrogen phosphate and paraffin oil are melt-extruded, and then stretched into a porous film according to the thermally induced phase separation method (TIPS). The key process parameters For: extruder temperature: 170°C, melt temperature: 160°C; casting temperature: 30°C; stretching temperature: 70°C; stretching speed ratio: 6 times. The porous film obtained in this example has the following characteristics: thickness: 50 μm; porosity: 30%; air permeability: 200s / 100cc; strength: greater than or equal to 35Mpa; tortuosity: 15; pore diameter: 10nm.

Embodiment 2

[0046] A functional diaphragm for a lithium ion battery in this embodiment includes a polypropylene diaphragm base material and a zirconium hydrogen phosphate functional material, wherein the added amount of zirconium hydrogen phosphate is 3% of the total amount of the polyethylene diaphragm base material. The functional separator is prepared by a wet process, and the key process parameters are: extruder temperature: 220°C, melt temperature: 205°C; casting temperature: 10°C; stretching temperature: 90°C; stretching speed ratio :4 times. The porous film obtained in this example has the following characteristics: thickness: 30 μm; porosity: 50%; air permeability: 220s / 100cc; strength: greater than or equal to 35Mpa; tortuosity: 20; pore diameter: 30nm.

Embodiment 3

[0048] A functional separator for a lithium ion battery in this embodiment includes a polyethylene separator base material and a zirconium hydrogen phosphate functional material, wherein the added amount of zirconium hydrogen phosphate is 5% of the total amount of the polyethylene separator base material. The functional separator is prepared by a wet process, and the key process parameters are: extruder temperature: 190°C, melt temperature: 180°C; casting temperature: 60°C; stretching temperature: 100°C; stretching speed ratio : 8.5 times. The porous film obtained in this example has the following characteristics: thickness: 5 μm; porosity: 40%; air permeability: 20s / 100cc; strength: greater than or equal to 35Mpa; tortuosity: 3; pore diameter: 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com