Composite solid electrolyte material and preparation method and application thereof

A solid electrolyte and positive electrode material technology, applied in the field of composite solid electrolyte materials and their preparation, can solve the problems of low degree of dissociation, difficult to meet the needs of use, poor ion conductivity, etc., to achieve simple operation, excellent electrochemical performance, phase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

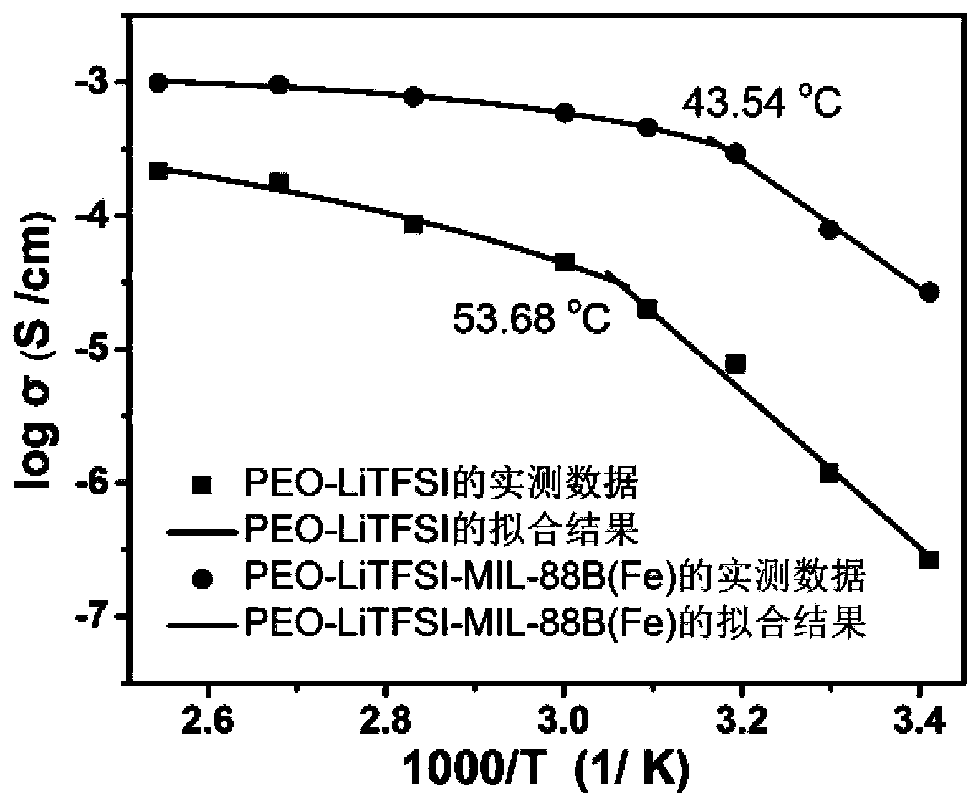

[0049] Stir 0.6g of PEO with a molecular weight of 4 million and 0.26g of LiTFSI in 15g of acetonitrile until uniform by magnetic force, pour it into a polytetrafluoroethylene mold, and then dry it in vacuum at 100°C for 24 hours. The phase transition temperature of the obtained polymer electrolyte is 53.86°C .

[0050] Add 0.07g MIL-88A (Cr, Fe), MIL-88B (V, Cr, Fe), MIL-88D (Cr, Fe) to the above electrolyte system, and the phase transition temperature of the electrolyte prepared by the same method is respectively The ionic conductivity at 50°C is 8.7×10 -5 S / cm, 8.9×10 -5 S / cm, 9.7×10 -5 S / cm, 1.6×10 -4 S / cm, 8.9×10 -5 S / cm and 9.6×10 -5 S / cm.

[0051] One-third of the ferric salt in the raw material of MIL-88B (Fe) is replaced with divalent nickel salt to prepare MIL-88B (FeNi 2 ), take 0.07g and add it to the above polymer electrolyte system, the phase transition temperature of the composite electrolyte prepared by the same method is 45.75°C, and the ionic conductiv...

Embodiment 2

[0056] Take 11g of N,N-dimethylformamide as solvent, 3g of 1,000,000 molecular weight PEO and 9g of Mg(PF 6 ) 2 Disperse it, stir it until it is uniform, cast it into a polytetrafluoroethylene mold, and then transfer it to 120°C for vacuum drying for 24 hours. The phase transition temperature of the obtained electrolyte is 63.7°C.

[0057] After adding 0.06g of MIL-96(Al,Cr) and Eu-BTC to the same system, the phase transition temperatures of the electrolytes prepared by the same method were 49.8°C, 47.8°C and 45.7°C, respectively, and the ion migration number at 60°C are 0.28, 0.40 and 0.38.

Embodiment 3

[0061] Grind 0.6g of PEO and 0.2g of KTFSI with a molecular weight of 5 million in an agate mortar and mix evenly, then transfer to a circular mold with a diameter of 2cm and extrude at 80°C with a pressure of 10MPa for 12h to obtain a polymer electrolyte membrane. It is 59.4°C.

[0062] In the above polymer electrolyte system, add 1g MIL-68 (Al, Fe), the phase transition temperature of the electrolyte prepared by the same method is 48.3 ℃ and 47.4 ℃ respectively, and the ionic conductivity at 45 ℃ is 7.9× 10 -5 S / cm and 7.5×10 -5 S / cm.

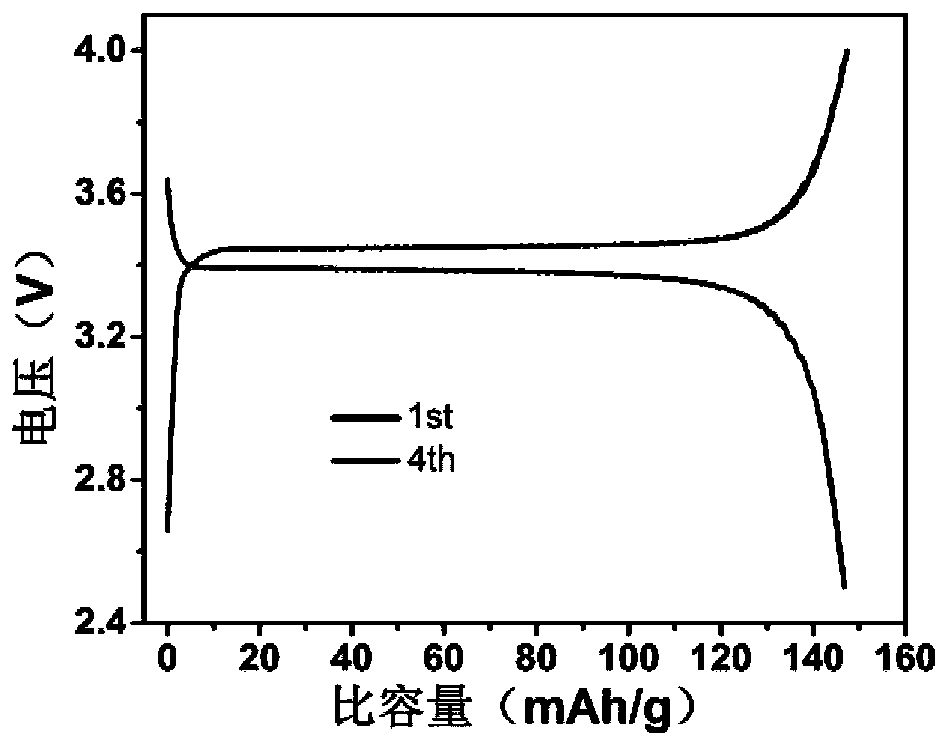

[0063] Replace one-half of the ferric salt in the raw material of MIL-68 (Fe) with ferrous salt to obtain MIL-68 (Al / Fe), MIL-68 (Fe III / Fe II ), added to the same system with the same mass, and the phase transition temperatures of the electrolytes prepared by the same method were 46.1°C and 46.6°C, respectively. When applied to the potassium-sulfur battery system at 50°C, the initial discharge specific capacity at 0.2C rate reached 1228...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com