Method for separating soybean protein powder by dry method

A soybean protein powder and dry process technology, applied in the field of food processing, can solve problems such as poor separation of protein bodies, and achieve the effects of being convenient to eat, rich in natural protein, and having a delicate and smooth taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

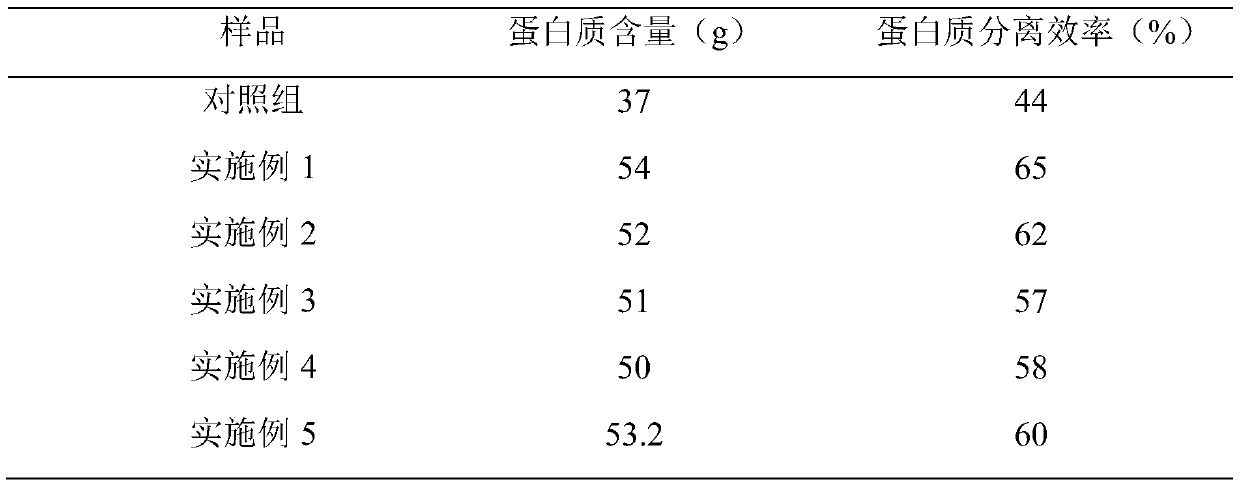

Examples

Embodiment 1

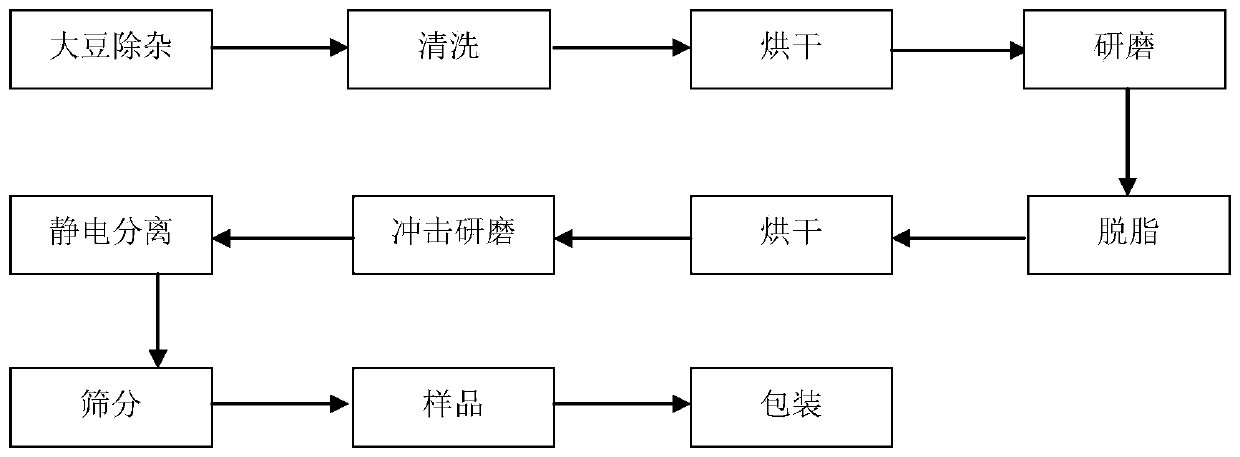

[0040] A method for dry separation of soybean protein powder is characterized in that it comprises the following steps:

[0041] (1) Take whole soybeans with plump grains, no moths, and no damage to the skin, and place them in an oven at 50°C for pre-drying, so that the moisture content is 6-8.5%;

[0042] (2) coarsely grinding the pre-dried soybeans in step (1), the grinding speed is 2000rpm, and the feed rate is 0.5kg / h;

[0043] (3) Put the soybean powder ground in step (2) into a Soxhlet extractor equipped with petroleum ether for degreasing for 6 hours, then wash with distilled water three times, and place in a fume hood to completely evaporate the residual petroleum ether , the ratio of soybean flour to acetone is 1:4, and the temperature of petroleum ether is 40°C;

[0044] (4) drying the soybean flour defatted in step (3) in a microwave heating drier, the microwave power is 900W, and the processing time is 7min;

[0045](5) Grind the defatted soybean meal in step (4)...

Embodiment 2

[0048] A method for dry separation of soybean protein powder is characterized in that it comprises the following steps:

[0049] (1) Take whole soybeans with plump grains, no moths, and no damage to the skin, and place them in an oven at 50°C for pre-drying, so that the moisture content is 6-8.5%;

[0050] (2) coarsely grinding the pre-dried soybeans in step (1), the grinding speed is 2000rpm, and the feed rate is 0.5kg / h;

[0051] (3) Put the soybean powder ground in step (2) into a Soxhlet extractor equipped with petroleum ether for degreasing for 6 hours, then wash with distilled water three times, and place in a fume hood to completely evaporate the residual petroleum ether , the ratio of soybean flour to acetone is 1:5, and the temperature of petroleum ether is 40°C;

[0052] (4) drying the soybean flour defatted in step (3) in a microwave heating drier, the microwave power is 900W, and the processing time is 7min;

[0053] (5) Grind the defatted soybean meal in step (4...

Embodiment 3

[0056] A method for dry separation of soybean protein powder is characterized in that it comprises the following steps:

[0057] (1) Take whole soybeans with plump grains, no moths, and no damage to the skin, and place them in an oven at 50°C for pre-drying, so that the moisture content is 6-8.5%;

[0058] (2) coarsely grinding the pre-dried soybeans in step (1), the grinding speed is 2000rpm, and the feed rate is 0.5kg / h;

[0059] (3) Put the soybean powder ground in step (2) into a Soxhlet extractor equipped with petroleum ether for degreasing for 6 hours, then wash with distilled water three times, and place in a fume hood to completely evaporate the residual petroleum ether , the ratio of soybean flour to acetone is 1:3, and the temperature of petroleum ether is 30°C;

[0060] (4) drying the soybean flour defatted in step (3) in a microwave heating drier, the microwave power is 900W, and the processing time is 7min;

[0061] (5) Grind the defatted soybean meal in step (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com