Cerium-doped zinc oxide photocatalyst and preparation method thereof

A photocatalyst, zinc oxide technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the difficult and controllable preparation of catalytic degradation efficiency catalysts, etc. problem, to achieve a good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a cerium-doped zinc oxide photocatalyst, comprising the following steps:

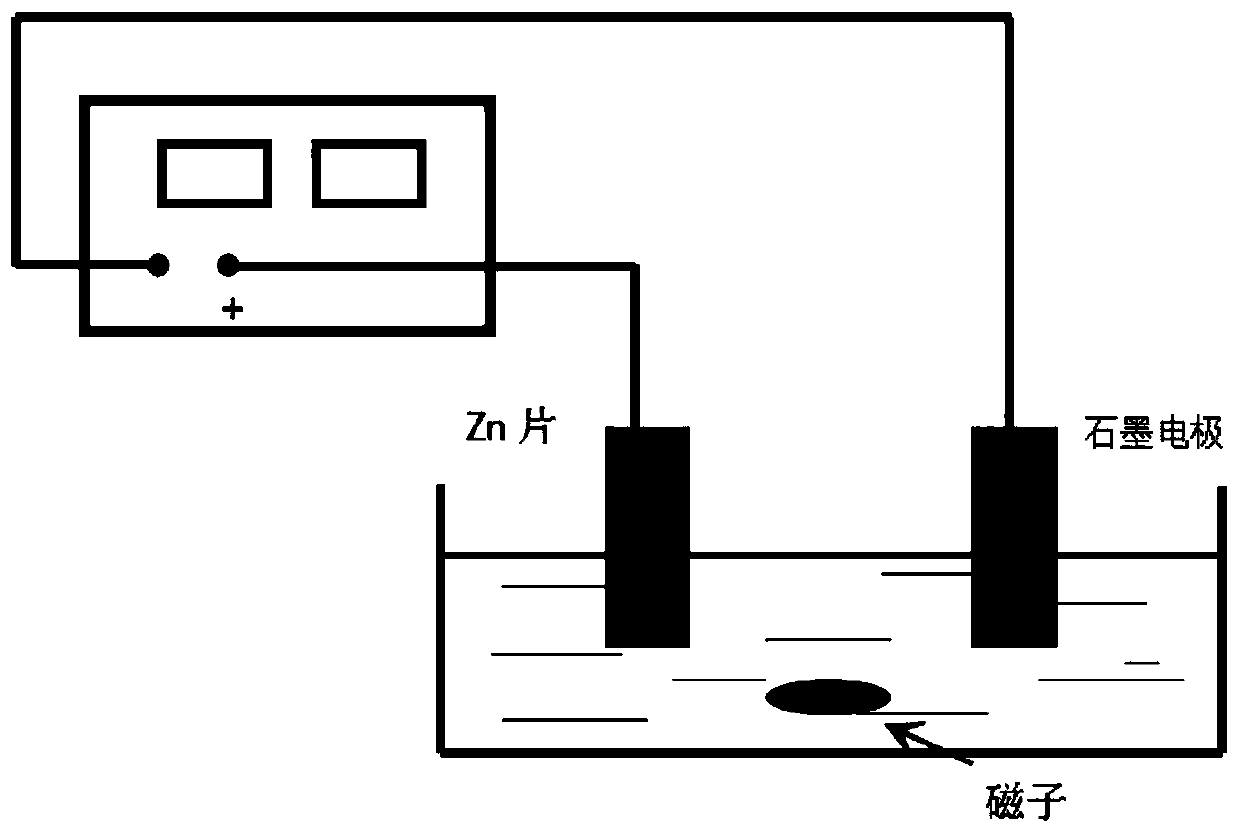

[0025] With zinc as the anode and the inert electrode as the cathode, it contains conductive salt, Ce 3+ The aqueous solution of 2-methylimidazole is electrolyzed as a conductive solution to obtain Ce / ZIF-8;

[0026] The Ce / ZIF-8 is calcined to obtain a cerium-doped zinc oxide photocatalyst.

[0027] The present invention uses zinc as the anode and the inert electrode as the cathode to contain conductive salt, Ce 3+ The aqueous solution of 2-methylimidazole is electrolyzed as a conductive solution to obtain Ce / ZIF-8.

[0028] In the present invention, the anode is preferably a zinc sheet, the thickness of the zinc sheet is preferably 0.05-1 mm, and the width is preferably 1-2 cm. The present invention has no special limitation on the length of the zinc flakes, and the length can be selected according to the amount of zinc flakes.

[0029] In the p...

Embodiment 1

[0042] Take 50mL of deionized water, add KCl to make the concentration 1.0mol L -1 KCl solution, adding Ce(NO 3 ) 3 ·6H 2 O 0.025g, 2-methylimidazole 3.8g, stirring and dissolving; Get Zn sheet 1g, clean the oxide film on Zn sheet surface and make anode, and graphite sheet is done negative electrode, press figure 1 Connect the device, the constant current is 0.018A·cm -2 The current density is reacted until the anode Zn sheet dissolves up to 98%, the power is turned off, the electrolyte is taken out and filtered, the gained solid is washed with deionized water to neutrality, and dried to obtain Ce / ZIF-8; the obtained Ce / ZIF-8 is In a muffle furnace at a heating rate of 5° C. / min, the temperature was increased to 500° C. for 3 h, and after cooling, a 0.5% Ce / ZnO photocatalyst (the cerium accounted for 0.5% of the total mass of the Ce / ZnO photocatalyst) was obtained.

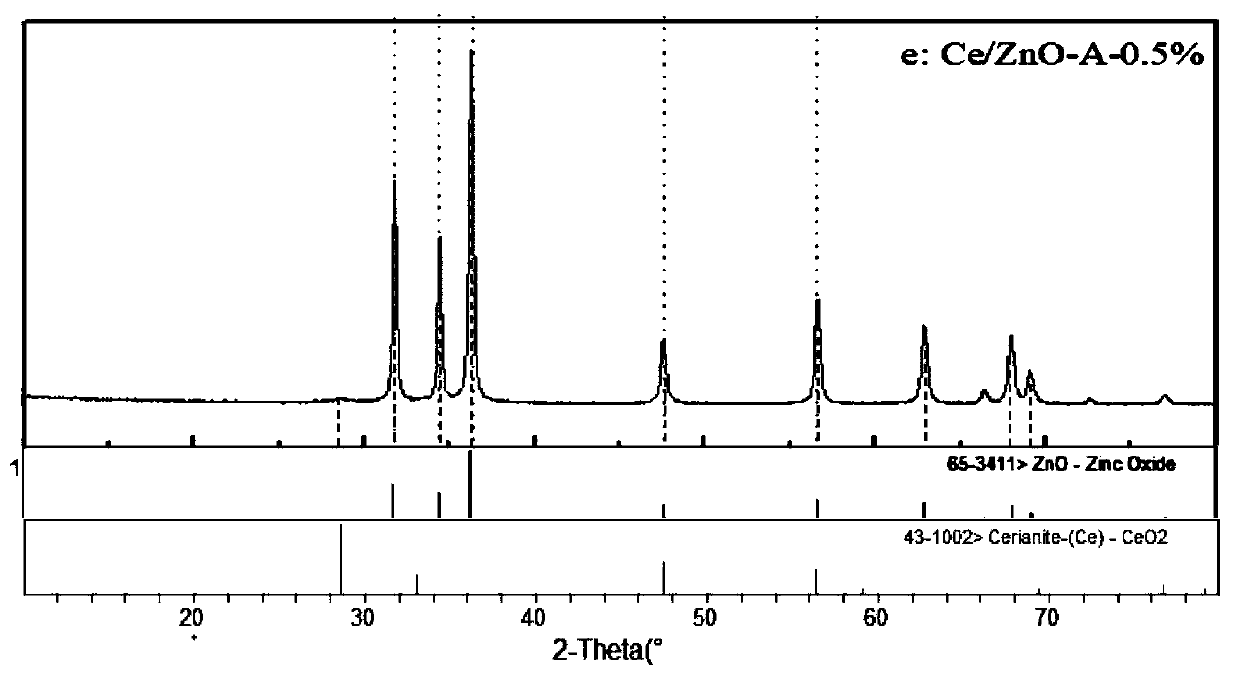

[0043] figure 2 It is the XRD pattern of the Ce / ZnO photocatalyst obtained in 1 in the embodiment. Depe...

Embodiment 2

[0046] Take 50mL of deionized water, add KCl to make the concentration 1.0mol L -1 KCl solution, adding Ce(NO 3 ) 3 ·6H 2 O 0.1g, 2-methylimidazole 3.8g, stirring and dissolving; Get 1g of Zn sheets, remove the oxide film of Zn sheets and clean them as anodes, graphite sheets as cathodes, press figure 1 Connect the device, the constant current is 0.018A·cm -2 The current density is reacted until the anode Zn sheet dissolves up to 98%, the power is turned off, the electrolyte is taken out and filtered, the gained solid is washed with deionized water to neutrality, and dried to obtain Ce / ZIF-8; the obtained Ce / ZIF-8 is In a muffle furnace at a heating rate of 5° C. / min, the temperature was increased to 500° C. for 3 h, and after cooling, a 2% Ce / ZnO photocatalyst was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com