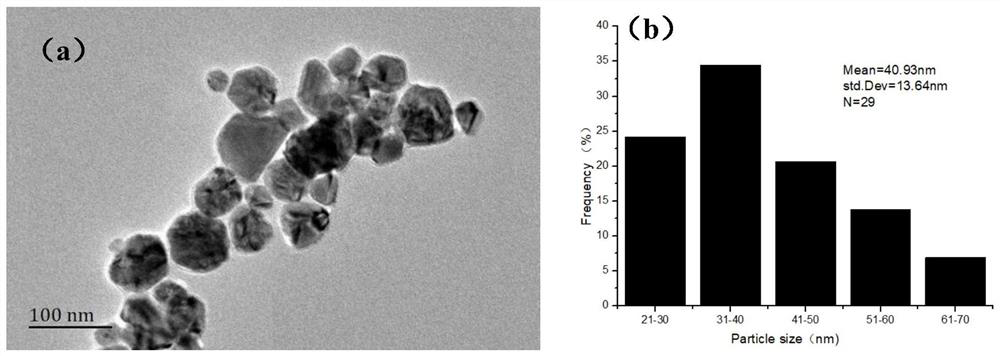

A green preparation method and application of copper nanoparticles based on citrus pectin

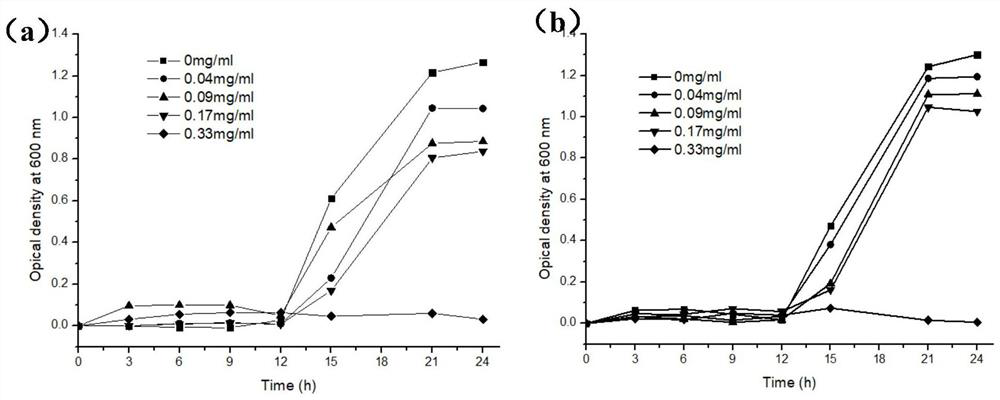

A technology of copper nano and pectin, which is applied in the field of green preparation of copper nanoparticles, can solve problems such as few reports, achieve short reaction time, prevent agglomeration, and improve monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

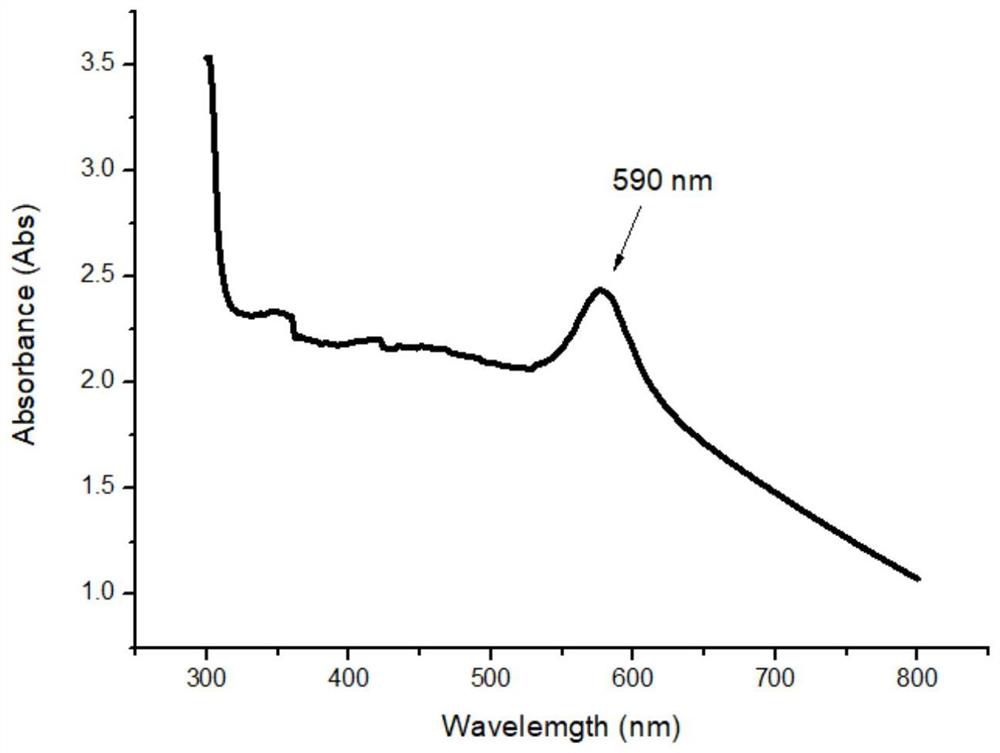

[0025] A method for preparing copper nanoparticles based on citrus pectin of the present invention, comprising the following steps:

[0026] Copper chloride is used as a copper precursor, alkali-soluble pectin as a stabilizer and reducing agent, ascorbic acid is also used as a reducing agent, and copper nanoparticles are synthesized by microwave assisted, and nano copper powder is obtained by high-speed centrifugal method. To overcome the shortcomings of the prior art, to provide a green environmental protection, low toxicity, low cost and high yield based on citrus pectin copper nanoparticle preparation method and its application.

Embodiment 1

[0028] A method for preparing copper nanoparticles based on citrus pectin of the present embodiment, comprising the following steps:

[0029] (1) Take 10mL 0.015mol / L CuCl 2 Place in a 50 mL Erlenmeyer flask;

[0030] (2) Add 10mL of 0.2% (w / v) pectin solution containing 5g / L sodium hydroxide and stir well;

[0031] (3) Add 2mL 10% (w / v) of ascorbic acid and stir well;

[0032] (4) Put the reaction reagent into a microwave oven with a power of 320W and heat it for 3min;

[0033] (5) After the obtained flocculent liquid and its precipitate are bottled and left for 6h, the filtration treatment is carried out to filter the obtained Shangqing night;

[0034] (6) Take the filtered liquid high-speed centrifugation, centrifugal conditions of 10000rpm, centrifugal time of 10min, remove the supernatant, add equal volume distilled water sonication, repeat centrifugation three times;

[0035] (7) The product of step (6) was dried overnight at 50 °C, and the resulting reddish-brown powder was...

Embodiment 2

[0039] The present embodiment is substantially the same as Example 1, the difference is that the concentration of sodium hydroxide (step (2)) is different, respectively, 0g / L, 1g / L, 2g / L, 3g / L, 4g / L, 6 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com