Oil sludge drying system and method for drying oil sludge through system in cooperation with chemical agent

A chemical agent, drying technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. Accelerate the natural evaporation of water, good economic feasibility, and the effect of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

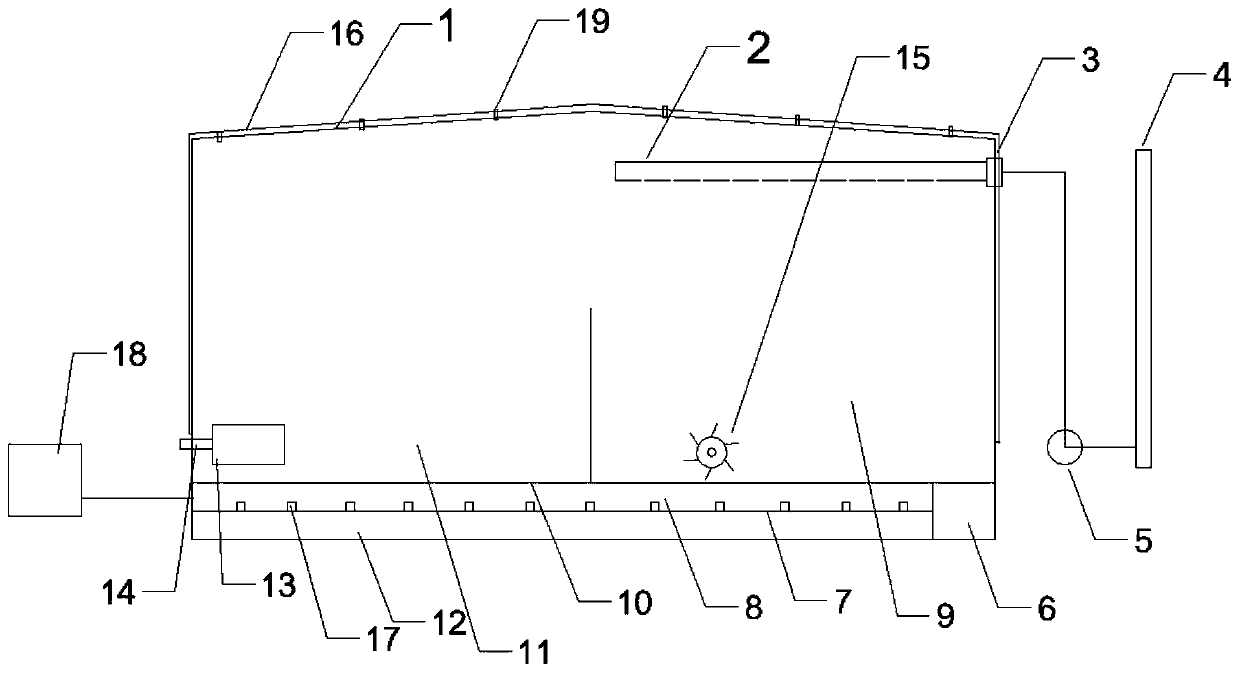

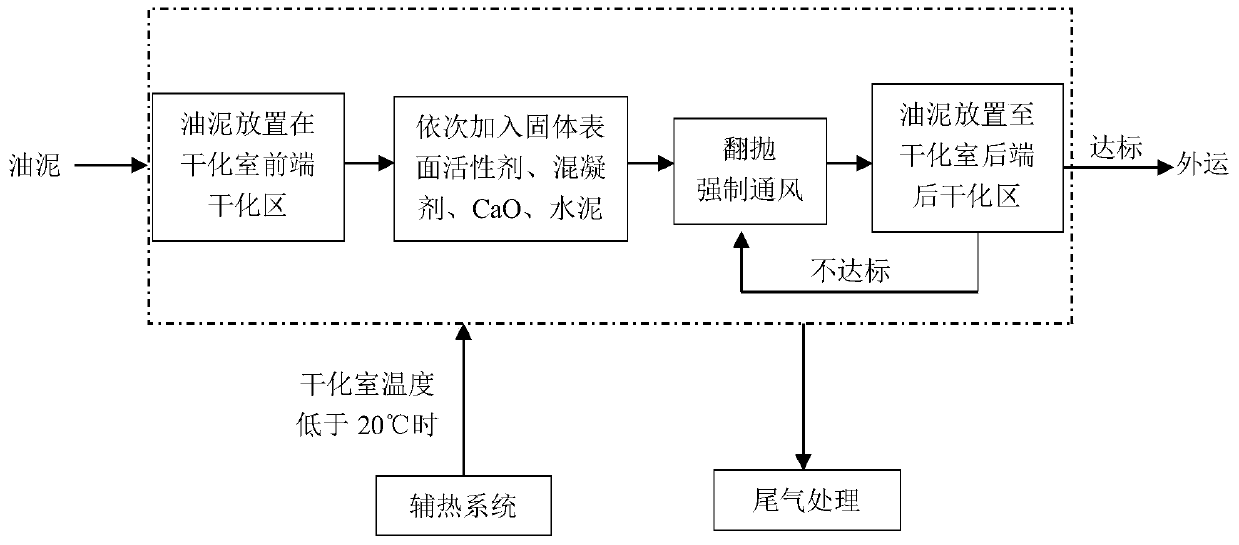

[0058] A sludge drying system, mainly composed of a drying chamber, a drying bed 10, a ventilation system, an auxiliary heating system, and a liquid accumulation system. The length, width, and height of the drying chamber = 40.0m×15.0m×4.0m, and a herringbone ceiling 1 , the distance between the herringbone ceiling 1 and the heavy-duty floor 8 of the drying chamber is 9.5m, and the drying bed 10 consists of a 0.2m heavy-duty floor 8, a 0.02m floor heating radiator 17, a heat insulation layer 7, and a 1.0m anti-corrosion chamber from top to bottom. Infiltration layer 12, the ventilation system is composed of an air inlet pipe 14 with a diameter of 1.0m, a drying tank 13, an air outlet pipe 2 with a diameter of 0.5m, an induced draft fan 3, a burner 5, and a chimney 4; the air outlet pipe 2 and the induced draft fan 3, The burner 5 and the chimney 4 are connected, and the air inlet pipe 14 and the air outlet pipe 2 are respectively arranged on the two left and right walls of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com