Preparation method and application of glycosylated hesperetin

A technology of hesperetin and glycosylation, applied in the field of bioengineering, can solve the problems of low bioavailability of hesperetin, insignificant effect, low solubility of hesperetin, etc. The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of glycosylated hesperetin, its concrete steps comprise:

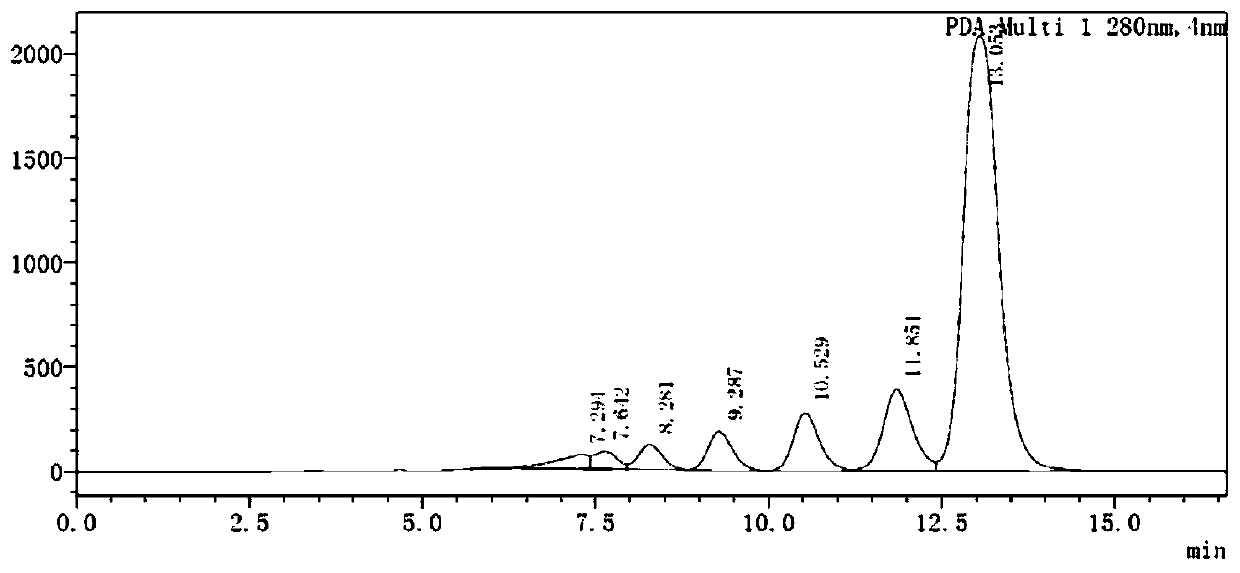

[0032] Using hesperidin as raw material, the reaction buffer is disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 0.5%, the pH of the reaction buffer is 6.2, the ratio of raw material to reaction buffer is 1:20, and the reaction temperature is 40 °C, the reaction time is controlled for 12 hours, then rhamnosidase:glucosyltransferase=10:90 in the reaction system, the mass fraction of the total enzyme is 10% of the added hesperidin. Add 100g 90% hesperidin, the glycosyl donor is glucose, and the concentration is 5g / L. In this reaction system, 152.2g (n=1-9) of polyglucoside hesperetin is obtained, and the yield is 90.5%. No hesperidin was detected by HPLC. see results figure 1 ,from figure 1 It can be seen that this reaction can effectively prepare the polysaccharide hesperetin. Due to the difference in the number of sugar groups linked by the polysaccharide ...

Embodiment 2

[0034] A kind of preparation method of glycosylated hesperetin, its concrete steps comprise:

[0035] Using hesperidin as raw material, the reaction buffer is disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 0.5%, the pH of the reaction buffer is 6.2, the ratio of raw materials to reaction buffer is 1:10, and the reaction temperature is 40 °C, the reaction time was controlled for 12h. Then in the reaction system rhamnosidase:glucosyltransferase=60:40, the mass fraction of the total enzyme is 13% of the input hesperidin. Add 100g of 90% hesperidin, the glycosyl donor is glucose, and the concentration is 1g / L. In this reaction system, 72.0g of monoglucoside hesperetin is obtained, with a yield of 95.0%. No orange peel is detected by HPLC Glycosides are present.

Embodiment 3

[0037] A kind of preparation method of glycosylated hesperetin, its concrete steps comprise:

[0038] Using hesperidin as raw material, the reaction buffer is disodium hydrogen phosphate-sodium citrate buffer with a mass fraction of 0.5%, the pH of the reaction buffer is 6.2, the ratio of raw material to reaction buffer is 1:50, and the reaction temperature is 40 °C, the reaction time was controlled for 12h. Then in the reaction system rhamnosidase:glucosyltransferase=50:50, the mass fraction of the total enzyme is 8% of the input hesperidin. Drop in 100g 98% hesperidin, the glycosyl donor is glucose, and the concentration is 2g / L. In this reaction system, 71.2g (n=1-9) of monoglucoside hesperetin is obtained, and the yield is 90.5%. No hesperidin was detected by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com