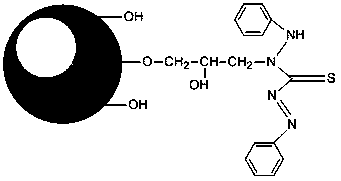

Preparing method of polysaccharide-based microsphere with dithizone structure

A technology of dithizone and microspheres, which is applied to the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve problems such as modification of dithizone, and achieve the effects of mild reaction conditions, broad application prospects and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

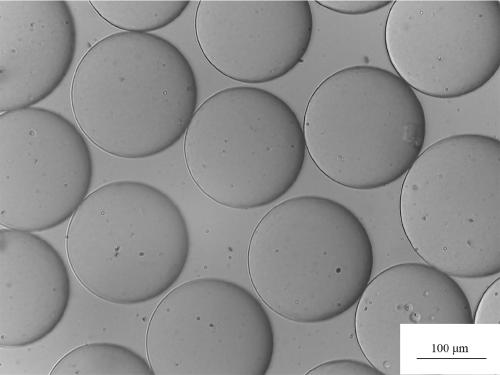

[0027] Weigh 4g of agarose, put it in 100mL of deionized water, and heat it to 90°C in a 250mL flask to dissolve; measure 400mL of liquid paraffin, put it in a 1L beaker, add 1g of Span 20, 3g of Span 60, and heat to 70°C. Slowly pour the agarose aqueous solution into liquid paraffin, stir at high speed, and slowly cool down to 25°C at a rate of 1°C / 2min. After the reaction is completed, filter out the microspheres, wash the microspheres with ethanol and deionized water respectively, sieve, and take Appropriate particle size range for use.

[0028] Drain the washed microspheres, weigh 10g of microspheres and put them in a 250mL flask, add 50mL of deionized water, 0.8g of PEG1000, and 10g of epichlorohydrin, and react at 40°C for 16h. The microspheres were washed with ethanol and deionized water, respectively.

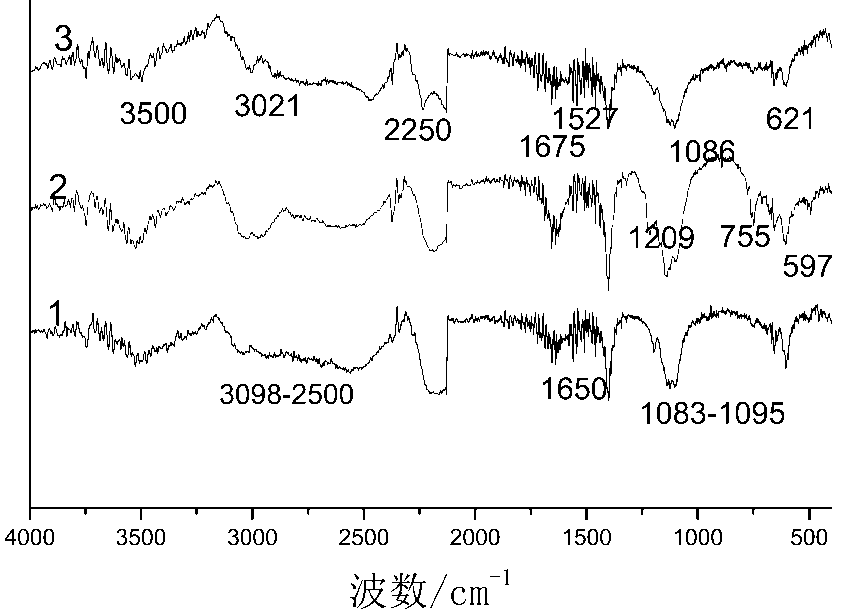

[0029] The washed microspheres were drained, weighed 10g of microspheres and placed in a 250mL flask, added 100mL of acetone solution containing 4g of dithizone, and r...

Embodiment 2

[0031] Weigh 4g of dextran, put it in 100mL of deionized water, and heat it to 80°C in a 250mL flask to dissolve; measure 300mL of cyclohexane, put it in a 1L beaker, add 4g of Span 80, heat to 80°C, and dissolve the agarose Slowly pour the aqueous solution into cyclohexane, stir at high speed, and slowly cool down to 25°C at a rate of 1°C / 2min. After the reaction is completed, filter out the microspheres, wash the microspheres with ethanol and deionized water, and sieve to obtain suitable particles. spare diameter range.

[0032] Drain the washed microspheres, weigh 10g of microspheres and put them in a 250mL flask, add 30mL of deionized water, 0.5g of PEG800, and 15g of epichlorohydrin, and react at 40°C for 16h. The microspheres were washed with ethanol and deionized water, respectively.

[0033] The washed microspheres were drained, weighed 10g of microspheres and placed in a 250mL flask, added 100mL of acetone solution containing 7g of dithizone, and reacted with mechani...

Embodiment 3

[0036] Weigh 8g of dextran in 100mL deionized water, heat to 80°C in a 250mL flask to dissolve; measure 600mL of cyclohexane, put it in a 1L beaker, add 4g of Span 80, 2g of oleic acid, and heat to 80°C , slowly pour the agarose aqueous solution into cyclohexane, stir at high speed, and slowly cool down to 25°C at a speed of 1°C / 2min. After the reaction is completed, filter out the microspheres, wash the microspheres with ethanol and deionized water, and sieve , take the appropriate particle size range for later use.

[0037] The washed microspheres were drained, weighed 10g of microspheres and placed in a 250mL flask, added 60mL of deionized water, 0.2g of tetrabutylammonium bromide, and 20g of epoxy bromide, and reacted at 40°C for 16h. The microspheres were washed with ethanol and deionized water, respectively.

[0038] The washed microspheres were drained, weighed 10g of microspheres and placed in a 250mL flask, added 100mL of acetone solution containing 5g of dithizone, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com