Polymer-skeleton interface enhancing agent simulating mussel foot adhesion and preparing method thereof

An interfacial enhancer, polymer technology, applied in the field of polymer-skeleton bonding, can solve the problems of easy delamination, the skeleton cannot play a strengthening role, and has no strong physical/chemical effects, and achieves the effect of improving the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

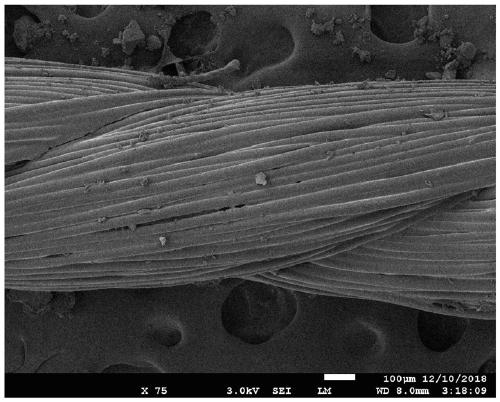

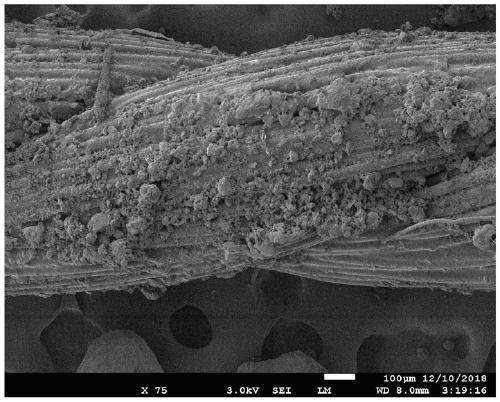

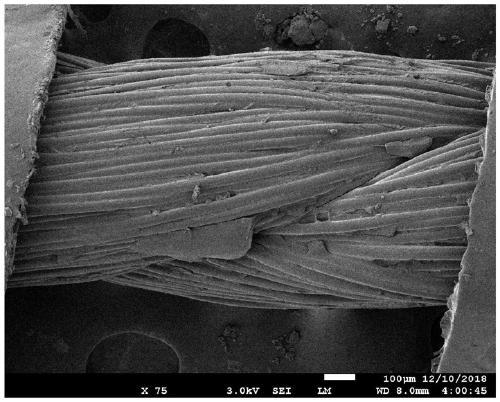

Image

Examples

Embodiment 1

[0042] A polymer-skeleton interface strengthening agent, which is composed of 100 parts by mass of chloroprene rubber, 50 parts by mass of silicon dioxide, 10 parts by mass of polyethyleneimine, 5 parts by mass of tea tannin, and 5 parts by mass of cobalt chloride. This interfacial enhancer adopts following steps to prepare:

[0043] 1) Under the conditions of 45°C and 1000r / min, with the assistance of tea tannin, add silicon dioxide to 100 parts by mass of water, and stir for 1 hour to prepare a silicon dioxide dispersion;

[0044]2) under the conditions of 60° C. and 4500 r / min, chloroprene rubber was added to 200 parts by mass of acetone, and stirred for 3 hours to obtain a chloroprene rubber solution;

[0045] 3) Under the conditions of 25°C and 1000r / min, firstly, stir and mix the prepared silica dispersion and neoprene solution for 1 hour; then, add cobalt chloride and polyethyleneimine in turn and stir for 1 hour to prepare Obtain polymer-skeleton interface enhancer di...

Embodiment 2

[0048] A polymer-skeleton interface enhancer, which is composed of: 100 parts by mass of water-soluble polyurethane, 0.05 parts by mass of graphene oxide, 0.01 part by mass of ethylenediamine, 0.01 part by mass of tannic acid, and 0.01 part by mass of ferric chloride. This interfacial enhancer adopts following steps to prepare:

[0049] 1) under the conditions of 25° C. and 3000 r / min, with the assistance of tannic acid, graphene oxide was added to 10 parts by mass of water, and stirred for 3 hours to prepare a graphene dispersion;

[0050] 2) Under the conditions of 25°C and 3000r / min, water-based polyurethane was added to 100 parts by mass of water, and stirred for 1 hour to obtain a polyurethane dispersion;

[0051] 3) Under the conditions of 25°C and 3000r / min, firstly, the prepared graphene dispersion and polyurethane dispersion were stirred and mixed for 5 minutes; then, ferric chloride and ethylenediamine were added in turn and stirred for 30 minutes to obtain a polymer...

Embodiment 3

[0054] A kind of polymer-skeleton interface strengthening agent, its composition is: 100 mass parts of phenolic resin, 1 mass part of montmorillonite nanosheet (a kind of clay), 3 mass parts of halloysite nanotube, 5 mass parts of silicon dioxide , 3 parts by mass of γ-aminopropyltriethoxysilane, 10 parts by mass of oak extract, and 10 parts by mass of manganese sulfate. This interfacial enhancer adopts following steps to prepare:

[0055] 1) Add montmorillonite nanosheets, halloysite nanotubes and silicon dioxide to 20 parts by mass of water under the condition of 60°C and 6000r / min, with the assistance of rubber extract, and stir for 15 minutes to prepare Obtain montmorillonite nanosheet / halloysite nanotube / silicon dioxide nanofiller dispersion;

[0056] 2) Add the phenolic resin to 50 parts by mass of ethanol at 25°C and 500 r / min, and stir for 1 hour to prepare a phenolic resin solution;

[0057] 3) Under the conditions of 25°C and 300r / min, firstly, stir and mix the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com