Solar cell, texturing method thereof and solar cell

A technology of solar cells and silicon wafers, which is applied in the field of solar cells, and can solve the problems of affecting the printability and contactability of subsequent pastes, affecting the filling factor of battery series resistance, cell efficiency, uneven PN junctions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

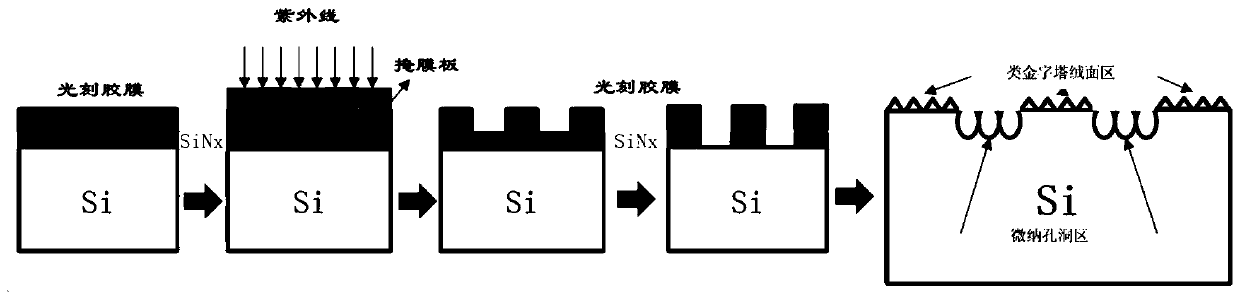

Method used

Image

Examples

Embodiment 1

[0147] 1.1 Texturing of solar cells

[0148] Processing object: polysilicon wafer, length 156.75mm×width 156.75mm×thickness 180μm;

[0149] S1: Alkali treatment:

[0150] The treatment agent is: potassium hydroxide solution (concentration 48%), 1.8L additive NNM-A2; wherein, the volume fraction of potassium hydroxide is 10%, the volume fraction of the additive is 0.7%, and the rest is water.

[0151] The silicon wafer was immersed in the above treatment agent, and treated at 79°C for 220s.

[0152] S2: pickling:

[0153] Pickling 1: use nitric acid solution with a volume fraction of 4%, and treat at 25°C for 85s;

[0154] Pickling 2: Then use a mixed acid solution of HF and HCl, and treat it at 30°C for 150s; in the mixed acid solution, the volume fraction of HF is 8.0%, the volume fraction of HCl is 9.0%, and the rest is water.

[0155] S3: Deposit protective film: Deposit Si on the front side of the silicon wafer by PECVD method 3 N 4 film layer with a thickness of 100...

Embodiment 2

[0183] 1.1 Texturing of solar cells

[0184] Processing object: polysilicon wafer, length 156.75mm×width 156.75mm×thickness 180μm;

[0185] S1: Alkali treatment:

[0186] The treatment agent is: potassium hydroxide solution (concentration 48%), 1.9L additive NNM-A2; wherein, the volume fraction of potassium hydroxide is 14%, the volume fraction of additive is 0.4%, and the rest is water.

[0187] The silicon wafer was immersed in the above treatment agent, and treated at 79°C for 220s.

[0188] S2: Pickling:

[0189] Pickling 1: use nitric acid solution with a volume fraction of 6%, and treat it at 25°C for 85 hours;

[0190] Pickling 2: Then use a mixed acid solution of HF and HCl, and treat it at 30°C for 150s; in the mixed acid solution, the volume fraction of HF is 6.0%, the volume fraction of HCl is 12.5%, and the rest is water.

[0191] S3: Deposit protective film: Deposit Si on the front side of the silicon wafer by PECVD method 3 N 4 film layer with a thickness o...

Embodiment 3

[0213] 1.1 Texturing of solar cells

[0214] Processing object: polysilicon wafer, length 156.75mm×width 156.75mm×thickness 180μm;

[0215] S1: Alkali treatment:

[0216] The treatment agent is: potassium hydroxide solution (concentration 48%), 2.0L additive NNM-A2; wherein, the volume fraction of potassium hydroxide is 12%, the volume fraction of additive is 0.5%, and the rest is water.

[0217] The silicon wafer was immersed in the above treatment agent, and treated at 79°C for 220s.

[0218] S2: pickling:

[0219] Pickling 1: use nitric acid solution with a volume fraction of 8%, and treat at 25°C for 85s;

[0220] Pickling 2: Then use a mixed acid solution of HF and HCl, and treat it at 30°C for 150s; in the mixed acid solution, the volume fraction of HF is 10%, the volume fraction of HCl is 7.5%, and the rest is water.

[0221] S3: Deposit protective film: Deposit Si on the front side of the silicon wafer by PECVD method 3 N 4 film layer with a thickness of 100nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com