Catalytic and sorptive articles comprising metal fiber felt substrates

A metal fiber felt and metal fiber technology, which can be applied in the directions of alkali metal compounds, metal/metal oxide/metal hydroxide catalysts, alkali metal oxides/hydroxides, etc., and can solve the problems of low effectiveness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The method of preparation of the metal fiber mat is not critical. Metal fiber mats are produced, for example, by a process involving sintering metal fibers under compression. Such methods are taught, for example, in Published US Patent Application No. 2011 / 0209451 by Kotthoff et al., which is incorporated herein by reference.

[0065]Metal fiber mats are highly porous and therefore exhibit a high degree of void volume (voids) or "true spaces" throughout their thickness. For example, prior to treating / supporting the catalyst and / or sorbent composition with the catalyst and / or sorbent composition, the metal fiber felt has a void volume of an average of about 20%, about 25%, about 30% of the total volume of the metal felt, About 35%, about 40%, about 45%, about 50% or about 55% to about 60%, about 65%, about 70%, about 75%, about 80%, about 85%, about 90% or about 95% %. In some embodiments, the void volume may average from about 20% to about 95% or about 50% of the tot...

Embodiment 1

[0136] Example 1: DOC comprising comparative cordierite matrix 1

[0137] The catalytic coating was applied to a 1" diameter x 3" long cordierite monolithic core at 400 cpsi by washcoat technique to provide 3.5 g / in 3 coating concentration and 120g / ft 3 A 1:1 weight ratio of Pt:Pd. In the catalytic powder used to prepare the coating slurry, Pt and Pd were supported on commercially available gamma alumina. Catalytic powders were prepared by incipient wetness impregnation of support materials with PGM precursors, followed by drying and calcination at about 500 °C. After coating the catalytic slurry, the core was dried and calcined at about 500°C.

Embodiment 2

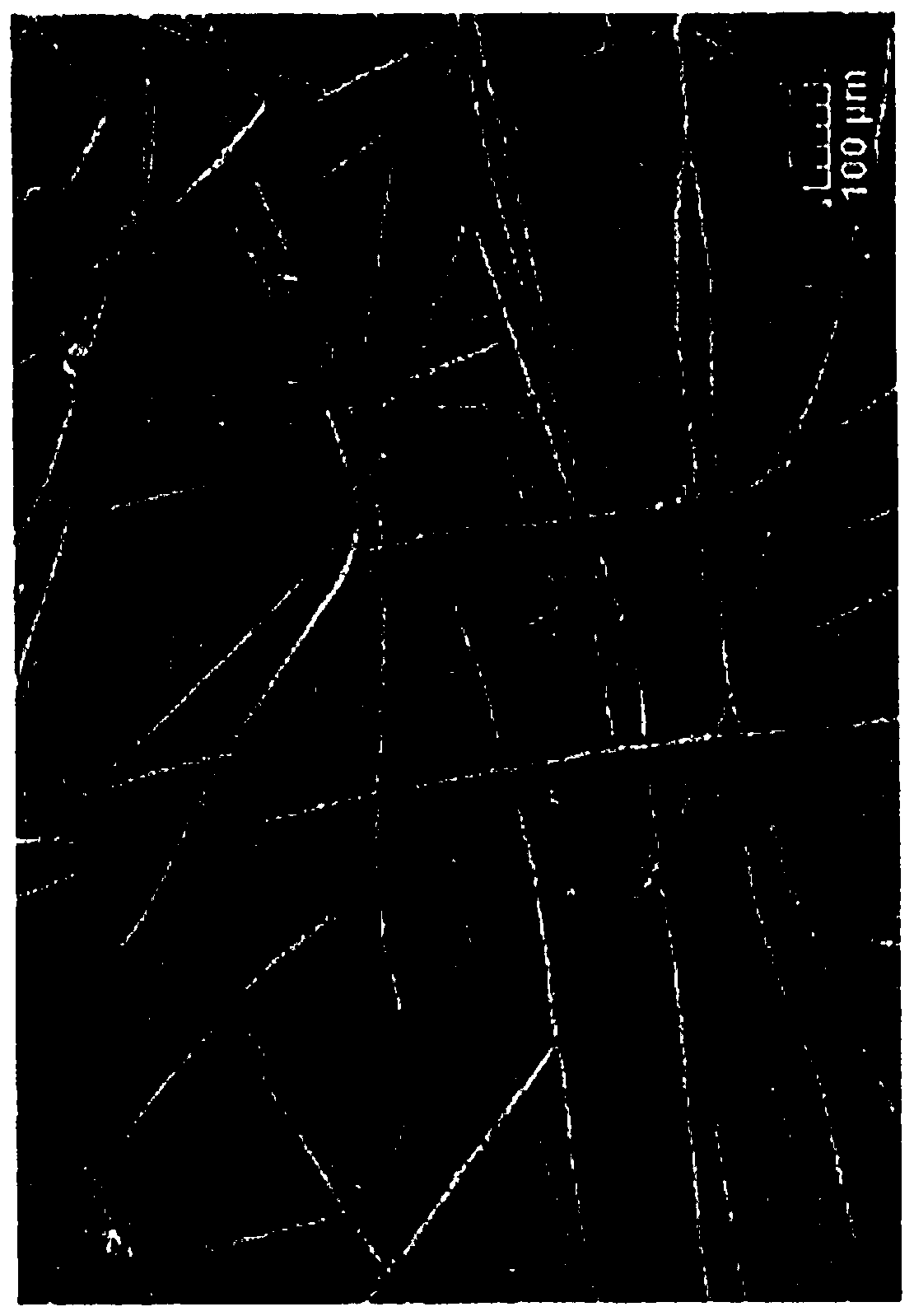

[0138] Example 2: DOC comprising a corrugated metal fiber mat matrix 1

[0139] The same coating as Comparative Example 1 was applied to a 1 inch diameter by 2 inch long corrugated fiber at 400 cpsi On the core, the same catalyst composition was applied in the same amount, then dried and calcined. Fiber metal felt is spongy and allows for easy application of washcoat slurries. Figure 5 is a photograph of a coated metal fiber felt of the present invention. Catalyst composition in the article of the present invention is with 5.2g / in 3 level application. Under this load, the voids in the metal felt are filled with the catalytic composition such that no gas flows through the channel walls except by diffusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com