Composite of Lanthanum Molybdate and Ferromagnetic Material and Its Application in Preparation and Adsorption of Phosphorus Removal

A ferromagnetic material, lanthanum molybdate technology, applied in alkali metal compounds, adsorbed water/sewage treatment, water pollutants, etc., can solve problems such as difficult solid-liquid separation, poor selectivity, and inability to realize recycling, so as to reduce risks , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the composite of lanthanum molybdate and ferromagnetic material comprises the following steps:

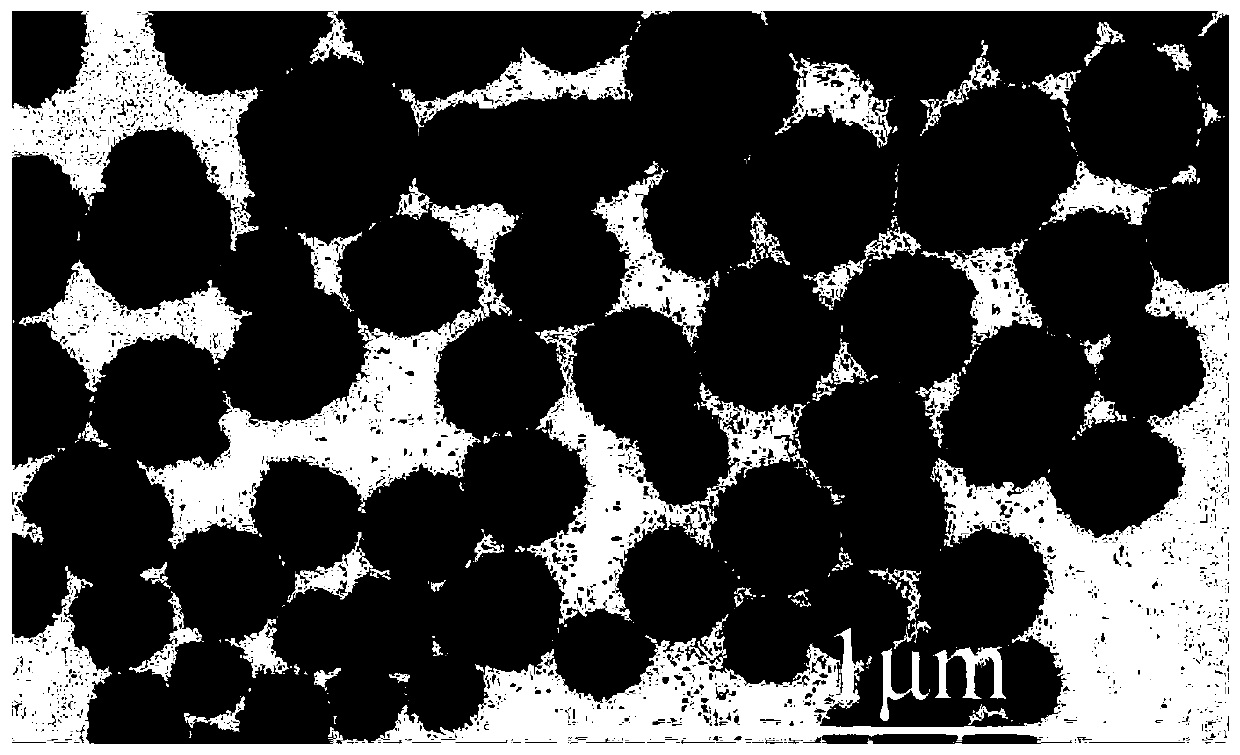

[0042] (1) Preparation of ferric oxide: 3.0g FeCl 3 ·6H 2 O and 0.72g of trisodium citrate were dissolved in 100ml of ethylene glycol, and then 4.8g of sodium acetate was dissolved in the above solution. After stirring for 0.5h under mechanical stirring conditions, they were put into a polytetrafluoroethylene reactor. React at -220°C for 8h-10h; after the reactor is cooled to room temperature, wash the black product with deionized water and ethanol for several times, and then vacuum-dry it. The lens diagram under the dispersion condition of the prepared ferroferric oxide is as follows figure 1 shown by figure 1 It can be seen that the ferroferric oxide crystals are dispersed with each other without agglomeration, which indicates that ferric oxide has good dispersion performance.

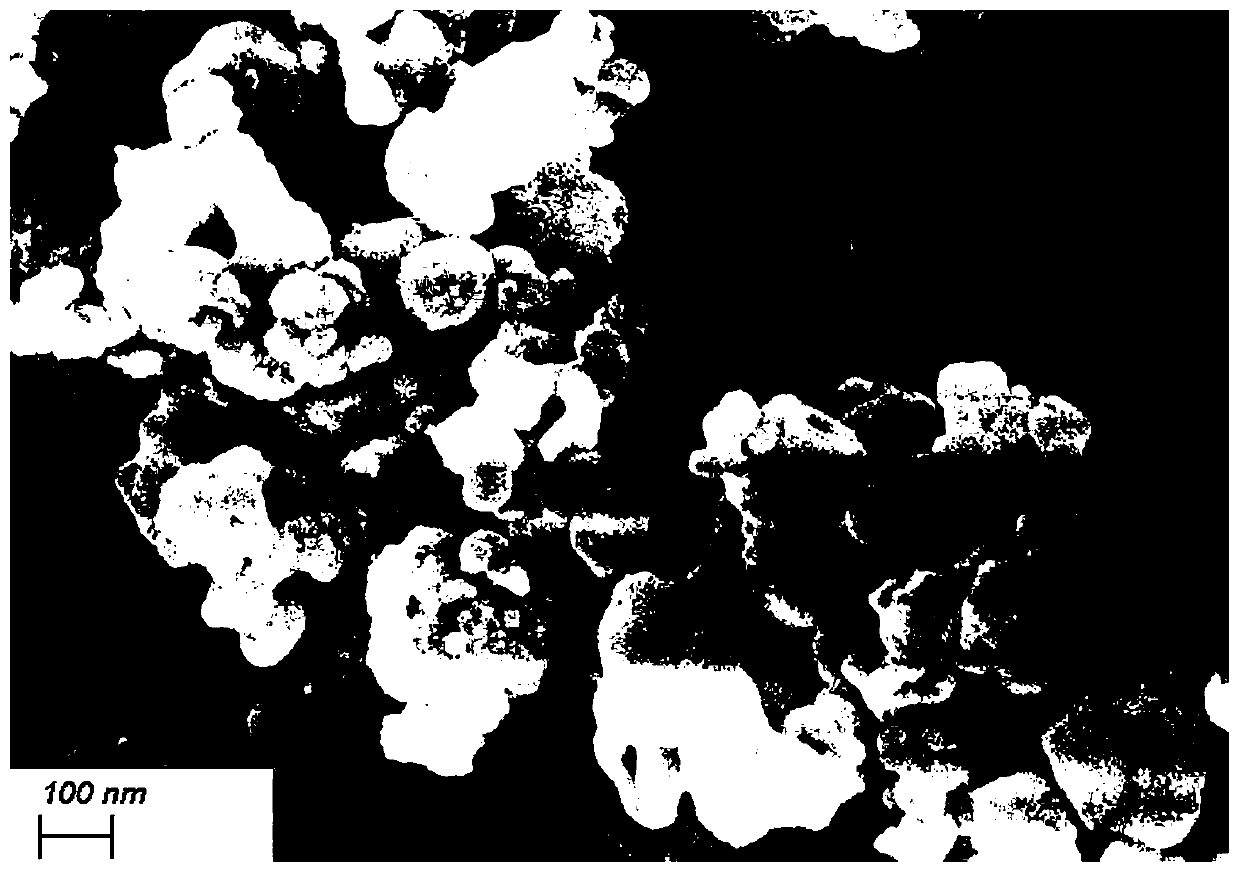

[0043] (2) 0.45g prepared Fe 3 o 4 After ultrasonic dispersion ...

Embodiment 2

[0050] Repeat Example 1 with the same steps as described, the difference is that the ferromagnetic material is γ-Fe 2 o 3 , the reaction time in the polytetrafluoroethylene reactor is 10h, the pH is adjusted to 8.0, and the reaction temperature is 200°C.

Embodiment 3

[0052] Repeat Example 1 with the same steps described above, the difference is that the ferromagnetic material is γ-Fe2O3, the reaction time in the polytetrafluoroethylene reactor is 12h, the pH is adjusted to 8.0, and the reaction temperature is 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com