Water-soluble titanium dioxide and preparation method thereof

A titanium dioxide, water-soluble technology, applied in the field of water-soluble titanium dioxide and its preparation, can solve the problems of uneven dispersion, titanium dioxide precipitation, affecting nanoparticles, etc., and achieve the effects of stable sol system, high energy efficiency, and difficult precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of water-soluble titanium dioxide provided by the invention specifically comprises the following steps:

[0034] Step 1, preparing a titanium compound solution with a concentration of 5-50wt% (weight percent);

[0035] Step 2, uniformly mix the titanium compound solution, alcohol, inorganic acid and organic acid to obtain a mixed solution, wherein the volume ratio of titanium compound solution: alcohol: inorganic acid: organic acid is 2-10:4:1-2:2- 3;

[0036] Step 3, stirring the mixed solution in step 2 at 90-130° C. for 30-120 minutes to obtain a heat treatment solution;

[0037] Step 4, add deionized water and alcohol to the heat treatment solution in step 3, and mix well to obtain an alcohol treatment solution, wherein the volume ratio of deionized water:alcohol:the titanium compound solution is 1-5:1-3:1 ~5;

[0038] Step 5, adding a modifier to the alcohol treatment solution in step 4, stirring for 30-60 minutes to obtain a dispers...

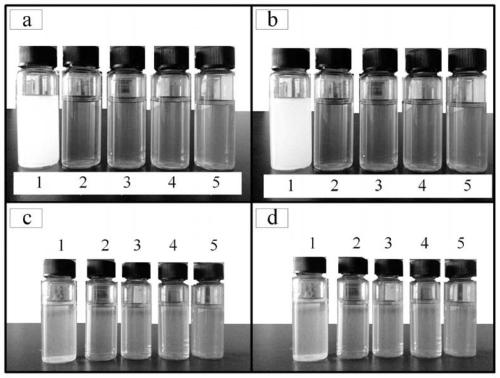

Embodiment 1

[0049] A preparation method of water-soluble titanium dioxide, specifically comprising the following steps:

[0050] Step 1, the preparation concentration is the titanium tetrachloride solution of 5wt%;

[0051] Step 2, take 10ml of titanium tetrachloride solution, 20ml of ethylene glycol, 5ml of perchloric acid and 10ml of oxalic acid, and mix them evenly to obtain a mixed solution;

[0052] Step 3, stirring the mixed solution in step 2 at 90°C for 120 minutes to obtain a heat treatment solution;

[0053] Step 4, add 10ml of deionized water and 10ml of ethylene glycol to the heat treatment solution in step 3, and mix well to obtain the alcohol treatment solution;

[0054] Step 5, add alanine to the alcohol treatment solution in step 4, stir for 45min to obtain a dispersion, wherein 0.1g of alanine is added to every 100mL alcohol treatment solution;

[0055] Step 6: Stir the dispersion in step 5 at 120°C for 13 days, then add 20ml of ethylene glycol to obtain a sol;

[0056] ...

Embodiment 2

[0058] A preparation method of water-soluble titanium dioxide, specifically comprising the following steps:

[0059] Step 1, the preparation concentration is the titanium sulfate solution of 8wt%;

[0060] Step 2, take 30ml of titanium sulfate solution, 20ml of diethanol, 5ml of periodic acid and 15ml of citric acid, and mix them evenly to obtain a mixed solution;

[0061] Step 3, placing the mixed solution in step 2 at 130°C and stirring for 30 minutes to obtain a heat treatment solution;

[0062] Step 4, add 30ml of deionized water and 15ml of diethanol to the heat treatment solution in step 3, and mix well to obtain the alcohol treatment solution;

[0063] Step 5, adding glycine to the alcohol treatment solution in step 4, stirring for 60 minutes to obtain a dispersion, wherein 3g of glycine was added to every 100mL alcohol treatment solution;

[0064] Step 6, place the dispersion in step 5 at 120°C and stir for 14 days, then add 40ml of diethanol to obtain a sol;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com