A dopo-containing acrylamide flame-retardant monomer, its preparation method and its application in flame-retardant materials

A technology of acrylamide, flame retardant monomer, applied in chemical instruments and methods, fire retardant coatings, epoxy resin coatings, etc., can solve the problems of poor flame retardant effect, degraded coating light transmittance, high cost, and achieve high transparency , excellent mechanical properties and transparency, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of DOPO-containing acrylamide flame retardant monomer

[0038] Add 20ml of tetrahydrofuran, 5.4000g of DOPO, 1.0250g of epichlorohydrin into a 250mL three-necked flask, stir under reflux, adjust the temperature to 60°C, react for 8h, concentrate the solution with a rotary evaporator, and store the viscous product in a vacuum oven at 80°C After drying for 3 hours, the final product is a transparent slightly viscous liquid, marked as DOPOE.

[0039] Add 0.06mol DOPOE, 0.06mol acrylamide and 260mL tetrahydrofuran into a 500mL flask, add 0.0005g p-hydroxyanisole at the same time, and stir at 50°C until the solution becomes clear. Then add 0.01 g of AlCl with stirring 3 , stirred until the solution becomes turbid, and the temperature is controlled at 60-80°C for 10 hours. During the reaction, HCl gas is released. The reaction is completed when no gas is generated when the reaction is measured by pH test paper. The obtained product is filtered while it...

Embodiment 2

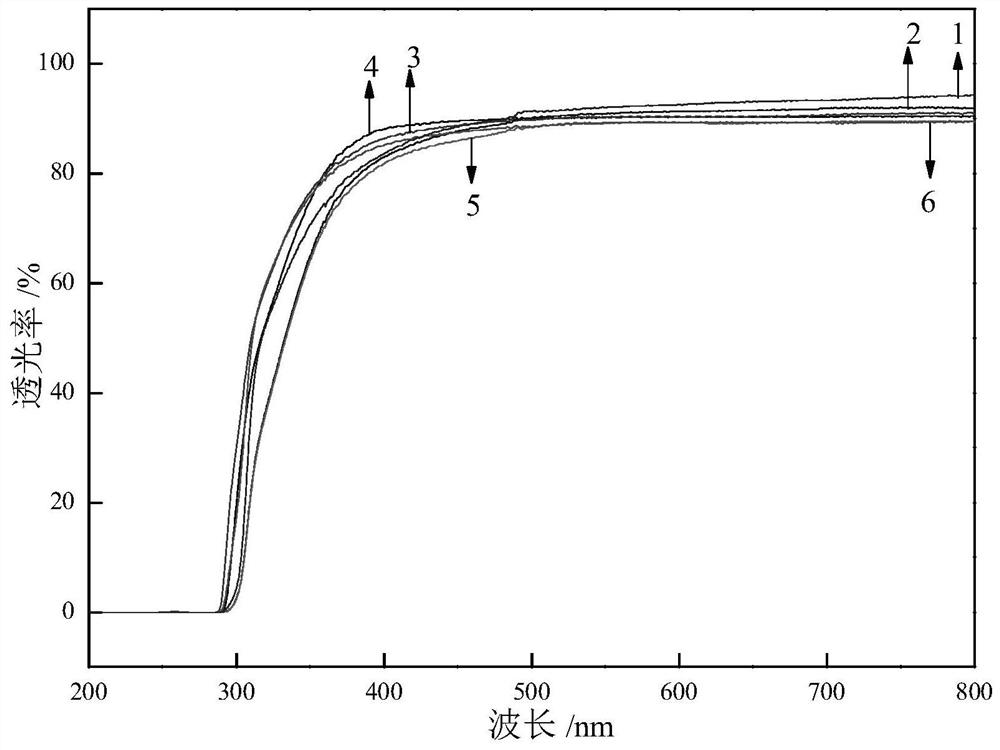

[0040] Example 2: Preparation of epoxy acrylate flame retardant material using DOPO-containing acrylamide flame retardant monomer

[0041] According to the formula shown in Table 1, weigh 1.0g of acrylamide (AM) and 1.0g of acrylic acid (AA) in a 50mL beaker, ultrasonically in a 1KW ultrasonic cleaner for 20min until dissolved; Add DOPOPE in the above solution, and ultrasonically disperse for 30min until the solution is uniform and transparent, then add 8-3.5g epoxy acrylate (EA), first mechanically stir evenly and then ultrasonically disperse for 30min, finally add 0.4g Darocur 1173 photoinitiator, Ultrasound for another 10 minutes until the system is uniformly dispersed, and DOPOPE flame-retardant epoxy acrylate coating can be prepared. It was coated on a glass plate with a wet film preparer with a coating thickness of 100 μm, and then with 800W / cm 2 It is irradiated with a high-pressure mercury lamp for 3 to 5 seconds to make it solidify and form a film, which is recorded ...

Embodiment 3

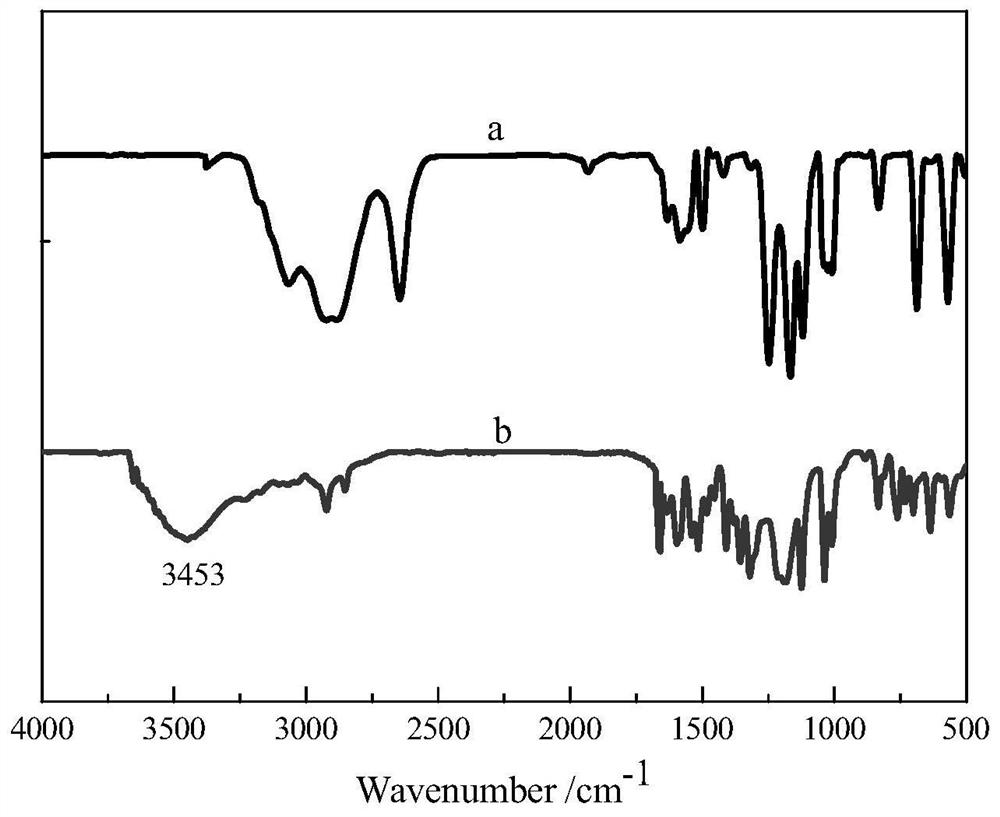

[0044] Example 3: Infrared Spectrum of DOPOPE-containing Acrylamide Flame Retardant Monomer DOPOPE

[0045] Take a small amount of solid sample and grind it in a mortar, add a certain amount of KBr to mix, grind it evenly, press it into a tablet on a tablet machine, and measure it in a Fourier transform infrared spectrometer (model Nicolet 380FT-IR); take a small amount of liquid sample and apply it to KBr wafer, measured in Fourier transform infrared spectrometer (model Nicolet 380FT-IR), measuring wave number range: 4000~500cm -1 .

[0046] Depend on figure 1 a is visible at 927cm -1 、856cm -1 The characteristic absorption peak of the epoxy group at the place disappears because the epoxy group in DOPO and epichlorohydrin reacts; and the 2386cm -1 There is no characteristic peak of P-H in DOPO, indicating that DOPO has been completely reacted; at the same time, 1489cm -1 The stretching vibration peak of P-Ph appeared at 1241cm -1 The stretching vibration peaks of P=O at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com