A kind of dihydrocarbyl dithiophosphoric acid modified zinc oxide nanoparticles and its preparation method and application

A technology of dihydrocarbyl dithiophosphate zinc and dihydrocarbyl dithiophosphoric acid, which is applied in the field of dihydrocarbyl dithiophosphate modified zinc oxide nanoparticles and its preparation, which can solve the problems of large particle size, harsh conditions, and complicated steps. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing zinc oxide nanoparticles modified with dihydrocarbyl dithiophosphoric acid, specifically: stirring 0.5 mL of 1.6 mol / L methanol solution of sodium hydroxide into 15 mL of 0.053 mol / L zinc dihydrocarbyl dithiophosphate (R 1 and R 2 They are n-butyl and n-octyl, respectively, and the specific structure is shown in Table 1), reacted at 40 °C for 10 h, and obtained a light yellow powder by rotary evaporation, washing, and drying, which is dihydrocarbyl dithiophosphoric acid modified zinc oxide nanoparticles grain.

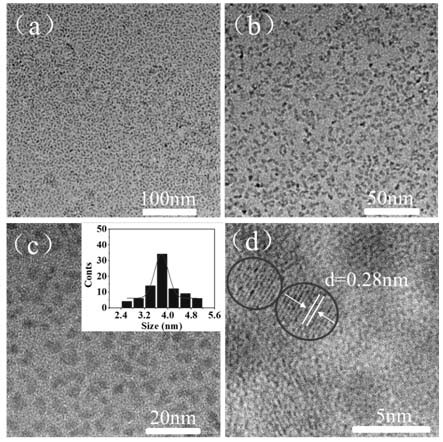

[0027] The transmission electron microscope pictures of the prepared dihydrocarbyl dithiophosphoric acid modified zinc oxide nanoparticles are shown in figure 1 . Depend on figure 1 It can be seen that the prepared dihydrocarbyl dithiophosphoric acid modified zinc oxide nanoparticles have a uniform particle size and an average particle size of 4 nm. The organic modifier dihydrocarbyl dithiophosphoric acid isolates the zinc oxide nanopa...

Embodiment 2

[0033] A preparation method for modifying zinc oxide nanoparticles with dihydrocarbyl dithiophosphoric acid, specifically: stirring 0.5 mL of 1.6mol / L potassium hydroxide in absolute ethanol solution and adding 15 mL of 0.053mol / L dihydrocarbyl dithiophosphoric acid Zinc phosphate (R 1 and R 2 The same is n-octyl, the specific structure is shown in Table 1), reacted at 30 °C for 12 h, and obtained a light yellow powder by rotary evaporation, washing and drying, which is dihydrocarbyl dithiophosphoric acid modified zinc oxide nanoparticles.

Embodiment 3

[0035] A method for preparing zinc oxide nanoparticles modified with dihydrocarbyl dithiophosphoric acid, specifically: 0.52 mL of tetraethylammonium hydroxide methanol solution (40 wt%) was stirred into 15 mL of 0.053mol / L dihydrocarbyl disulfide Zinc phosphate (R 1 and R 2 The same is n-octylbenzene, the specific structure is shown in Table 1), reacted at 30 °C for 14 h, and obtained a light yellow powder by rotary evaporation, washing and drying, which is zinc oxide nanoparticles modified with dihydrocarbyl dithiophosphoric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com