A kind of preparation method of quasicrystal reinforced aluminum matrix composite material

A composite material and reinforced aluminum-based technology, which is applied in the field of preparation of quasi-crystal reinforced aluminum-based composite materials, can solve the problems of reducing reinforcement and matrix diffusion, poor material strength and toughness, and not suitable for mass production, etc., to meet technical parameters Accurate and detailed, improving strength and hardness, and good product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

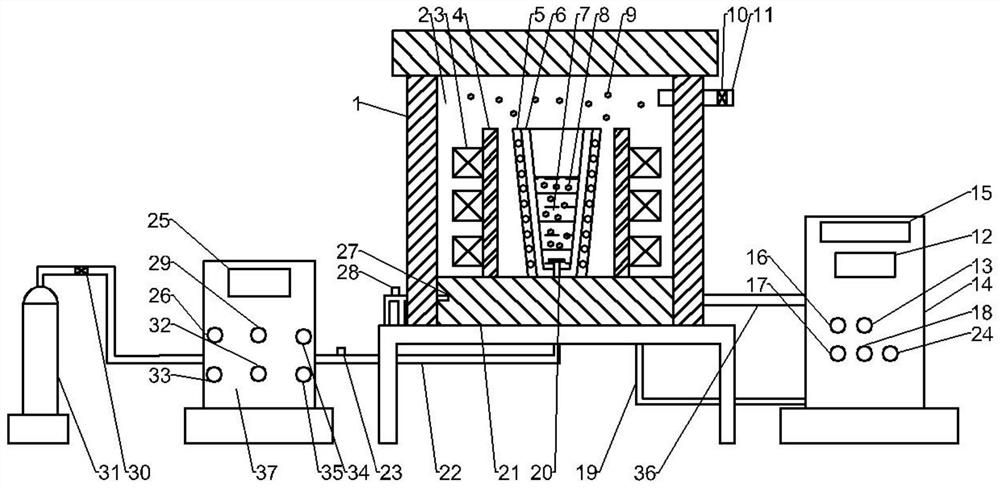

[0049] figure 1 As shown in the figure, it is the smelting state diagram of the quasi-crystal reinforced aluminum matrix composite material. The position and connection relationship of each part must be correct, and the operation should be carried out in sequence.

[0050] Quantities of chemicals used to prepare smelts are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0051] The vacuum smelting furnace 1 is vertical, and the inside of the vacuum smelting furnace 1 is a furnace cavity 2, and a workbench 21 is arranged below the furnace cavity; the two sides of the upper part of the workbench 21 are electromagnetic stirring devices 3 and are fixed on the fixed plate 4; There is a heater 5 outside the crucible 6, and inside the melting crucible 6 there are molten melting alloy 7 and added quasicrystal particles 8, and the who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com