A kind of method for preparing black polylactic acid fiber by dope coloring

A technology of polylactic acid fiber and polylactic acid, which is applied in the field of fiber production, can solve the problems of black fiber materials such as weak mechanical properties and color fastness, and achieve the effects of reducing energy consumption, easy control of color depth, and uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

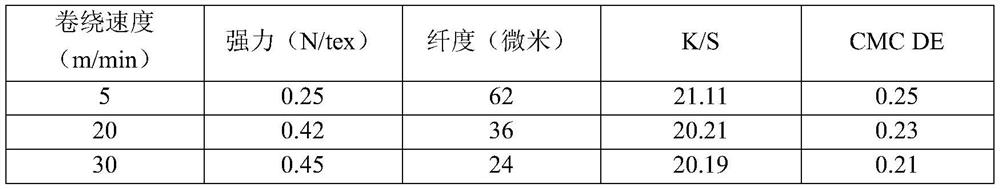

Examples

Embodiment 1

[0031] Place the polylactic acid in a vacuum oven at 80°C for 24 hours, take 10 g of the dried polylactic acid and 0.15 g of non-ionic modified carbon black with a surface-grafted polylactic acid structure in a flask, stir and mix them thoroughly, and then add them to the double-cone micro mixer. Refining instrument, adjust the screw speed to 60rpm, raise the temperature of the left and right plates to 190°C, after the polylactic acid is melted and extruded, it is drawn to a small winding machine, and the winding speed is adjusted to 20m / min. After a period of time, it will be wound on the winding machine The fiber on the machine is taken off, placed in a water bath at 70° C. for drawing for 30 seconds, the degree of orientation of the fiber is improved and its length is elongated to 2 times of the original fiber. Take it out and let it dry at room temperature.

[0032] Non-ionic modified carbon black with polylactic acid structure grafted on the surface: add 2.5g silane coupl...

Embodiment 2

[0033] The impact of embodiment 2 modified carbon black consumption on fiber product

[0034] Referring to Example 1, the amount of non-ionic modified carbon black was replaced by 0.1 g, 0.2 g, 0.25 g, 0.3 g, 1 g, and 2 g respectively, and other conditions remained unchanged, and corresponding fiber products were prepared. The specific performance results of the product are shown in Table 1.

[0035] The performance result of the fiber obtained by the consumption of different nonionic modified carbon blacks in table 1

[0036] The amount of modified carbon black Strength (N / tex) Soaping fastness K / S CMC DE 0.1g 0.22 5 19.63 0.45 0.15g 0.37 5 20.23 0.23 0.2g 0.29 5 21.38 0.31 0.25g 0.23 5 22.10 0.29 0.3g 0.15 5 23.09 0.28 1g 0.12 5 23.55 0.25 2g 0.10 5 23.58 0.26

Embodiment 3

[0038] Referring to Example 1, the drafting time was replaced by 10s, 20s, 60s, and 300s respectively, and other conditions remained unchanged, and corresponding fiber products were prepared. The specific results are shown in Table 2.

[0039] Table 2 Performance results of fibers obtained at different drawing times

[0040] Drawing time (s) Strength (N / tex) Soaping fastness K / S CMC DE 10 0.27 5 20.23 0.25 20 0.30 5 20.22 0.23 60 0.35 5 20.00 0.23 300 0.33 5 20.12 0.21

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com