Preparation method and application of amorphous CoMoS4/NiSe nanosheet array composite material

A nanosheet array and composite material technology, which is applied in the field of preparation of amorphous cobalt tetrathiomolybdate/nickel selenide nanosheet array composite materials, can solve the problem of difficulty in forming high energy density supercapacitors and reducing the energy storage capacity of supercapacitors , It is difficult to obtain high specific capacitance and other problems, to achieve the effect of promoting contact, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of composite materials

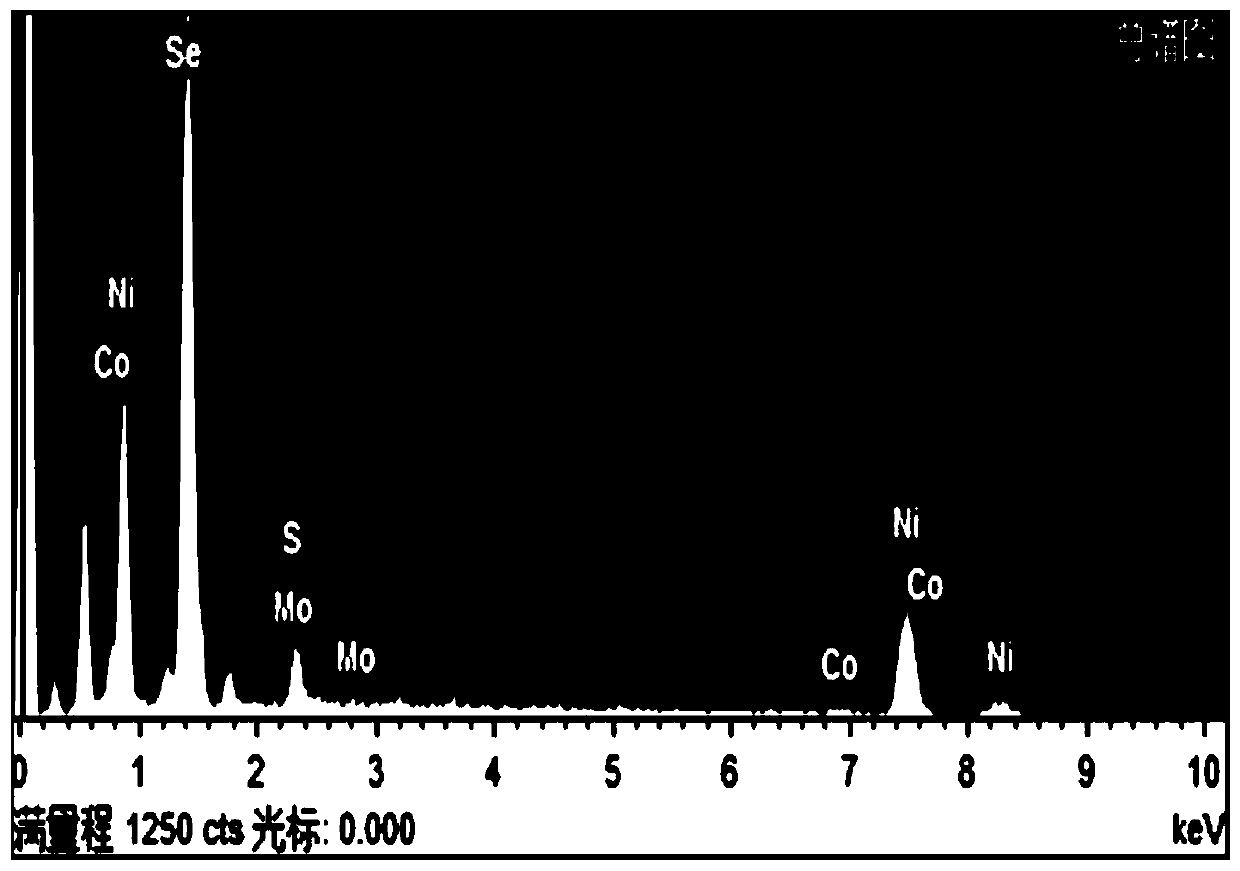

[0033] An amorphous CoMoS 4 The preparation method of / NiSe nano sheet array composite material, comprises the following steps:

[0034] Step 1. Add 5 mmol of cobalt nitrate hexahydrate, 2.5 mmol of sodium molybdate heptahydrate and 50 mL of deionized water into a 100 mL autoclave at room temperature, stir and dissolve to obtain a mixed aqueous solution A;

[0035] Step 2, immerse the cleaned foamed nickel in the mixed aqueous solution A, seal and heat the autoclave to 80°C for hydrothermal reaction, keep the temperature for 10 hours, and cool to room temperature to obtain the reaction product A;

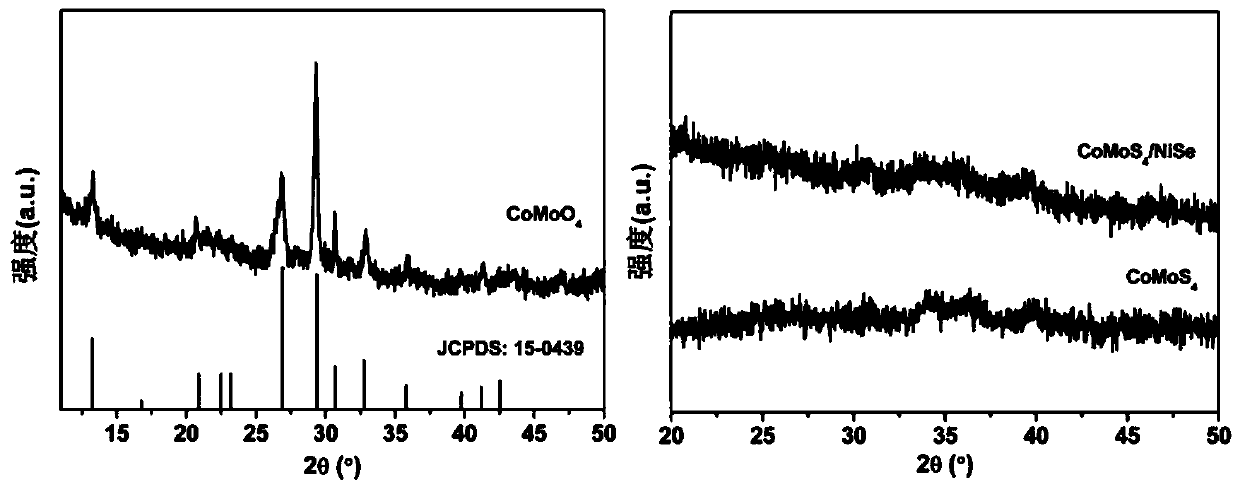

[0036] Step 3. Wash the reaction product A several times with deionized water and ethanol in sequence, and dry it in vacuum at 60°C for 12 hours to obtain CoMoO grown on nickel foam 4 nanosheet arrays;

[0037] Step 4, at room temperature, add 2mmol sodium sulfide and 50mL deionized water into a 100mL autoclave, stir and dissolve to o...

Embodiment 2

[0053] An amorphous CoMoS 4 The preparation method of / NiSe nano sheet array composite material, comprises the following steps:

[0054] Step 1. At room temperature, add 5 mmol cobalt nitrate hexahydrate, 10 mmol sodium molybdate heptahydrate and 75 mL deionized water into a 100 mL autoclave, stir and dissolve to obtain a mixed aqueous solution A;

[0055] Step 2, immerse the cleaned foamed nickel in the mixed aqueous solution A, seal and heat the autoclave to 180°C for hydrothermal reaction, keep the temperature for 4 hours, and cool to room temperature to obtain the reaction product A;

[0056] Step 3. Wash the reaction product A several times with deionized water and ethanol in sequence, and dry it in vacuum at 60°C for 12 hours to obtain CoMoO grown on nickel foam 4 nanosheet arrays;

[0057] Step 4, at room temperature, add 2mmol sodium sulfide and 70mL deionized water into a 100mL autoclave, stir and dissolve to obtain a sodium sulfide solution;

[0058] Step 5, growin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com