Method for preparing acetyl cholesterol-7-one p-toluenesulfonylhydrazone

A technology of p-toluenesulfonylhydrazone and toluenesulfonylhydrazide, which is applied in the field of preparing acetylcholesterol-7-ketone p-toluenesulfonylhydrazone, can solve the problems of product recovery damage, increase, unfavorable total yield, etc., and achieve reduction The effect of overall cost, improvement of preparation yield, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

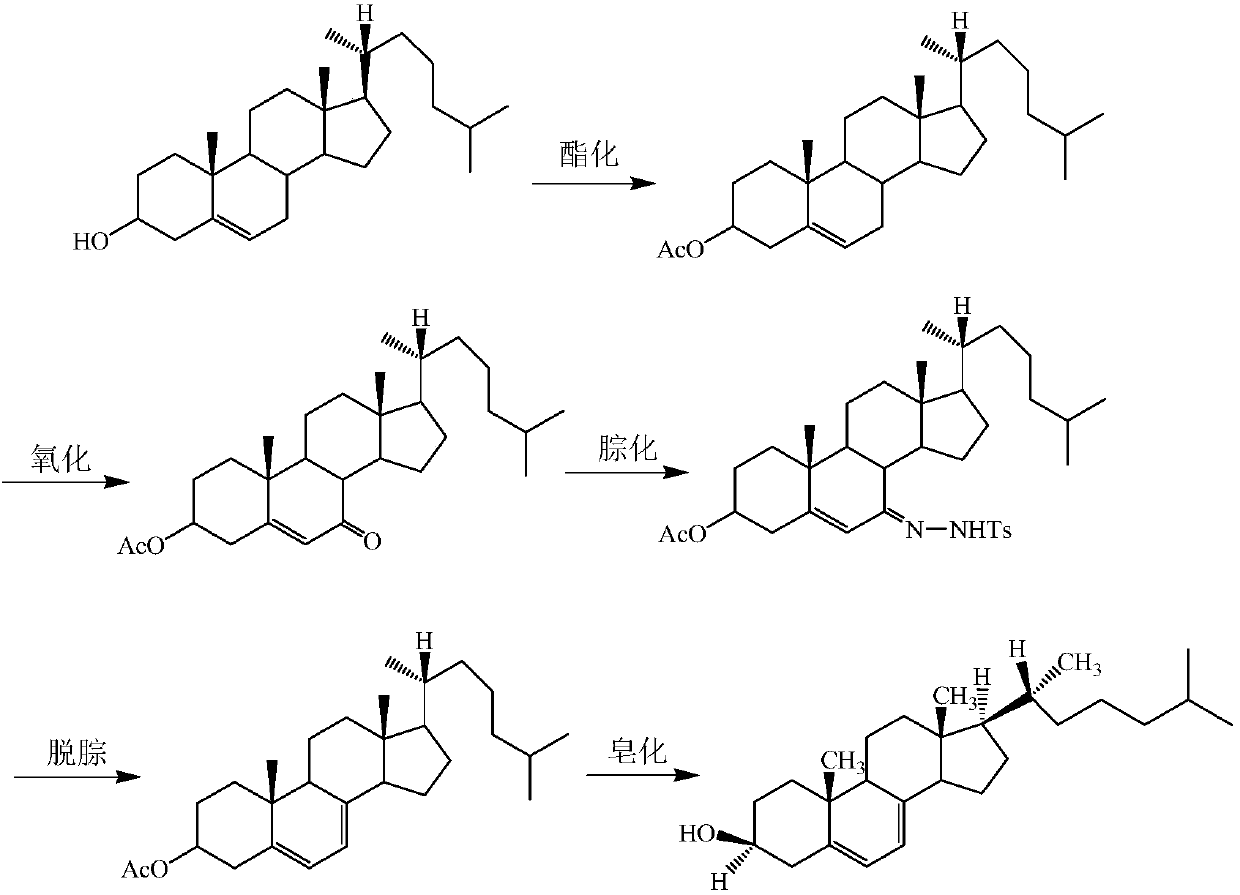

Image

Examples

Embodiment 1

[0037] This example is used to illustrate the method for preparing acetylcholesterol-7-one p-toluenesulfonyl hydrazone provided by the present invention

[0038] Put 50g (about 113mmol) of acetylcholesterol-7-one, 22.5g (about 121mmol) of p-toluenesulfonyl hydrazide, 150g of methanol, and 100g of petroleum ether into the reaction vessel, stir and disperse, and then add 2.5g of strongly acidic cationic resin. After feeding, stir and heat up to 50°C, and keep the temperature at 50±1°C for 4h.

[0039] After the heat preservation is finished, the strongly acidic cationic resin is removed by filtration, and 150 g of the mixed solvent is distilled off from the filtrate under reduced pressure. The remaining feed solution was slowly cooled to 0-5°C, filtered, washed with a small amount of methanol, and vacuum-dried to obtain 66.3 g of acetylcholesterol-7-one p-toluenesulfonylhydrazone, with a content of 98.2%.

Embodiment 2

[0041] This example is used to illustrate the method for preparing acetylcholesterol-7-one p-toluenesulfonyl hydrazone provided by the present invention

[0042] Put 50g (about 113mmol) of acetylcholesterol-7-one, 27.3g (about 147mmol) of p-toluenesulfonyl hydrazide, 250g of methanol, and 250g of petroleum ether into the reaction vessel, stir and disperse, and then add 15g of strong acidic cationic resin. After feeding, keep stirring at 25±1°C for 12 hours.

[0043] After the heat preservation is finished, the strongly acidic cationic resin is removed by filtration, and 400 g of the mixed solvent is distilled off from the filtrate under reduced pressure. Slowly cool the remaining feed solution to 0-5°C, filter, wash with a small amount of methanol, and vacuum-dry to obtain 66.9 g of acetylcholesterol-7-one p-toluenesulfonylhydrazone, with a content of 98.3%.

Embodiment 3

[0045] This example is used to illustrate the method for preparing acetylcholesterol-7-one p-toluenesulfonyl hydrazone provided by the present invention

[0046] Put 50g (about 113mmol) of acetylcholesterol-7-one, 40g (about 215mmol) of p-toluenesulfonyl hydrazide, 250g of ethanol, and 50g of petroleum ether into the reaction vessel, stir and disperse, and then add 10g of strongly acidic cationic resin. After feeding, stir and heat up to 40°C, and keep the temperature at 40±1°C for 4h.

[0047] After the heat preservation is finished, the strongly acidic cationic resin is removed by filtration, and 200 g of the mixed solvent is distilled off from the filtrate under reduced pressure. Slowly cool the remaining feed solution to 0-5°C, filter, wash with a small amount of ethanol, and vacuum-dry to obtain 67.1 g of acetylcholesterol-7-one p-toluenesulfonylhydrazone, with a content of 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com