A production process for preparing organic-inorganic composite water-retaining agent

A technology of inorganic compounding and production process, applied in the direction of organic fertilizers, fertilizer mixtures, other chemical processes, etc., can solve the problems of refractory degradation and the incompatibility of the organic-inorganic interface of the water-retaining agent, to prevent white pollution and improve the degree of tightness of the combination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

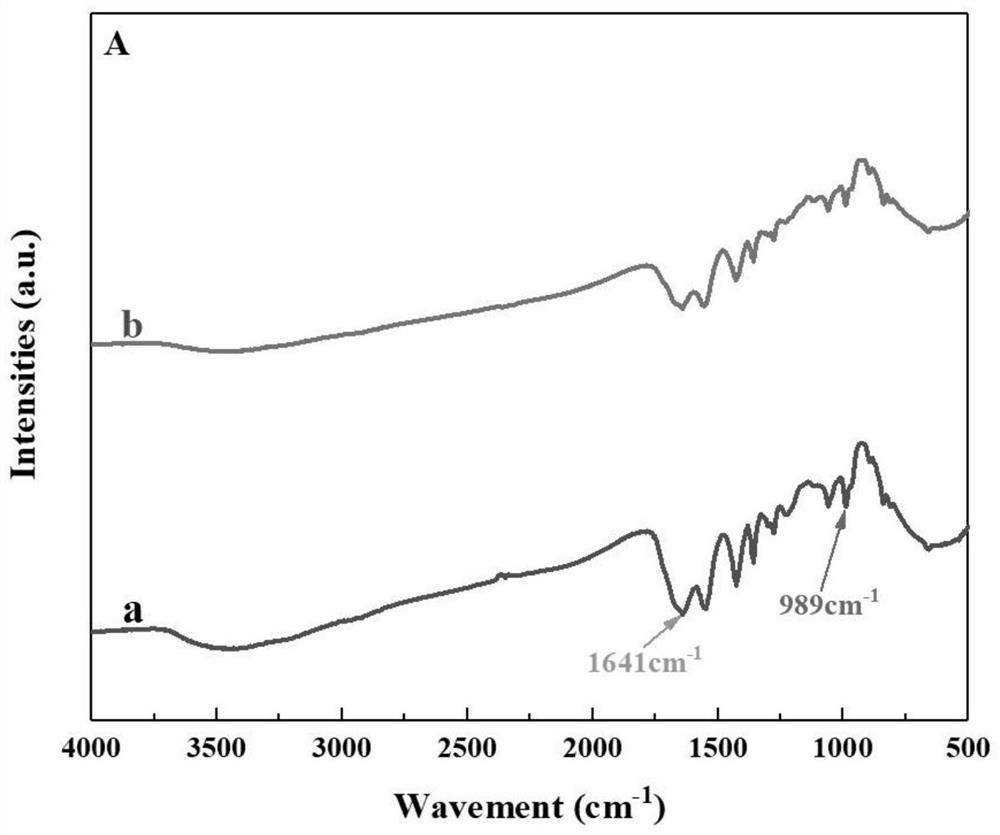

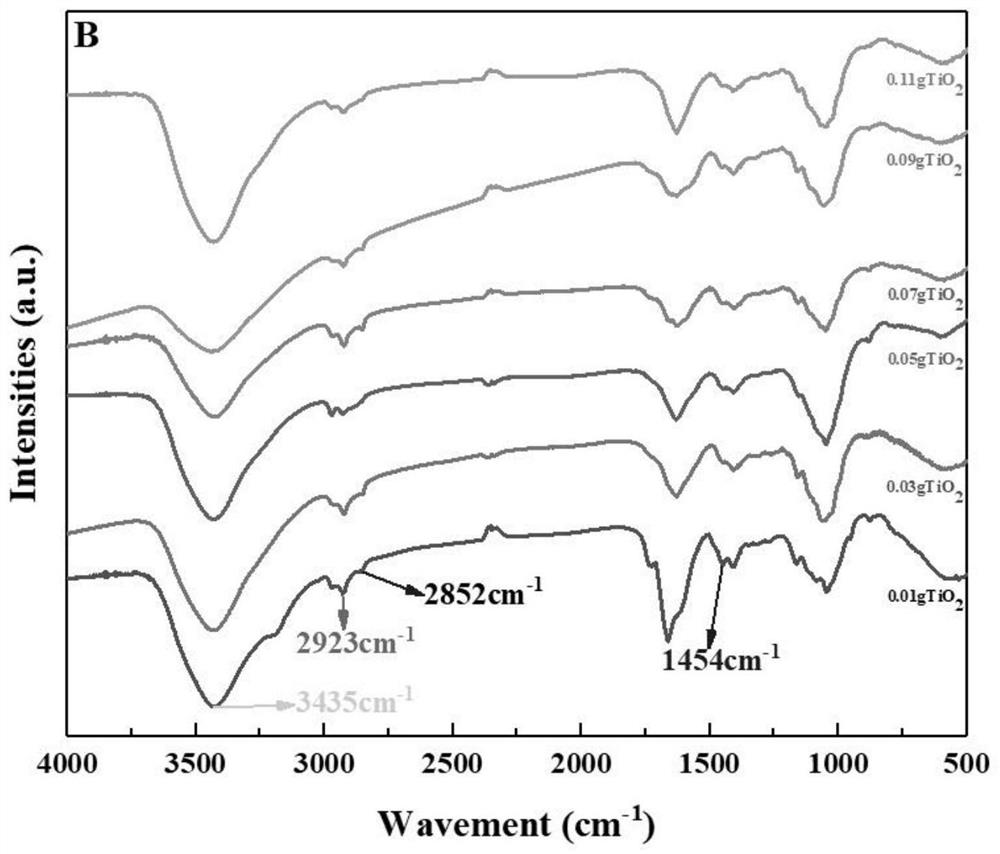

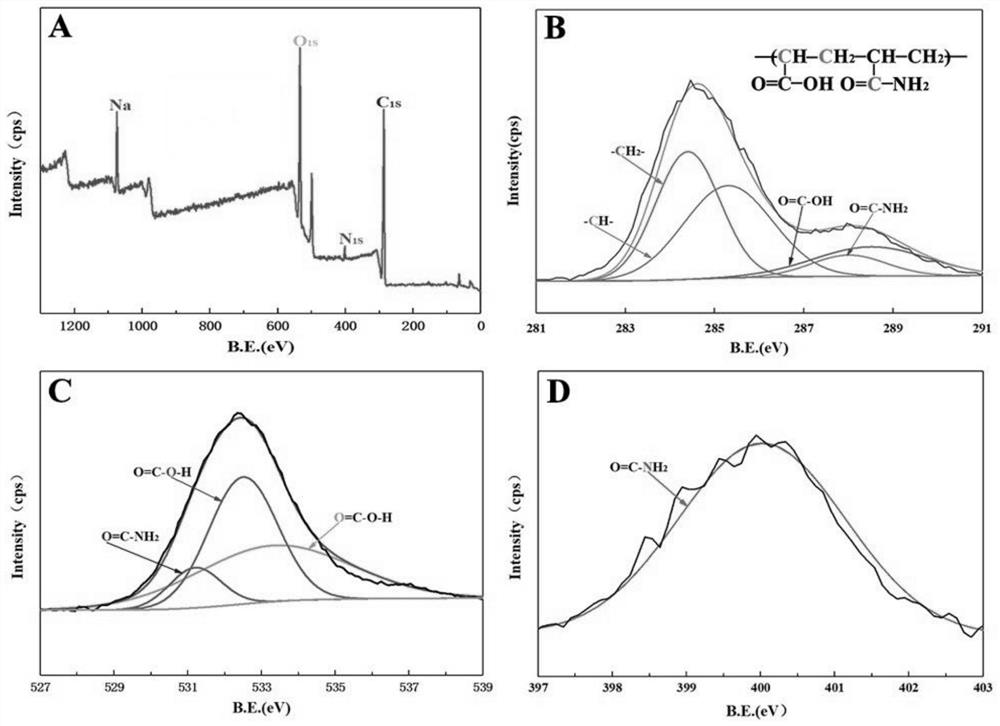

[0043] Example 1, a new type of preparation organic-inorganic composite water supply agent production process is prepared according to the following method;

[0044] A. After mixing the sodium hydroxide 9 g from deionized water, add 27 g of acrylic acid under the conditions of ice water bath,

[0045] B, 2G of the titanium dioxide dispersion liquid to 6 g of deionized water to obtain a B product; the titanium dioxide solid content in the titanium dioxide dispersion is 20%, and the particle size is 15 nm;

[0046] C. After mixing A product 9g, B product 0.2 g and acrylamide 1 g, using deionized water to 40 ml into the quartz pipe, and irradiated with 300 W ultraviolet light with 300 W ultraviolet light by 300 W Ultra-ultraviolet light, which is C Taste;

[0047] D, 0.036 g of N, N-methylene bis acrylamide, 0.24 g of ammonium sulfate and 48 g of deionized water, and D products;

[0048] e, under a nitrogen atmosphere, the D product 5g is mixed with the above C products and at a temp...

Embodiment 2

[0050] Example 2, a new type of preparation organic-inorganic composite water supply agent production process is prepared according to the following method;

[0051] A. After mixing the sodium hydroxide 9 g from deionized water, add 27 g of acrylic acid under the conditions of ice water bath,

[0052] B, 2G of the titanium dioxide dispersion liquid to 6 g of deionized water to obtain a B product; the titanium dioxide solid content in the titanium dioxide dispersion is 20%, and the particle size is 15 nm;

[0053] C, after mixing A product 9g, B product 0.6 g and acrylamide 1 g, using deionized water to 40 ml into the quartz pipe, irradiated with 300 W ultraviolet light with 300 W ultraviolet light by 300 W Ultraviolet light, which is C Taste;

[0054] D, 0.036 g of N, N-methylene bis acrylamide, 0.24 g of ammonium sulfate and 48 g of deionized water, and D products;

[0055] e, under a nitrogen atmosphere, the D product 5g is mixed with the above C products and at a temperature of...

Embodiment 3

[0057] Example 3, a new type of preparation organic-inorganic composite water supply agent production process is prepared according to the following method;

[0058] A. After mixing the sodium hydroxide 9 g from deionized water, add 27 g of acrylic acid under the conditions of ice water bath,

[0059] B, 2G of the titanium dioxide dispersion liquid to 6 g of deionized water to obtain a B product; the titanium dioxide solid content in the titanium dioxide dispersion is 20%, and the particle size is 15 nm;

[0060] C. After mixing A product 9g, B product 1g and acrylamide 1 g, using deionized water to 40 mL into the quartz pipe, irradiated with 300 W ultraviolet light with 300 W ultraviolet light at a nitrogen atmosphere to obtain a photopolymerization product, which is C product. ;

[0061] D, 0.036 g of N, N-methylene bis acrylamide, 0.24 g of ammonium sulfate and 48 g of deionized water, and D products;

[0062] e, under a nitrogen atmosphere, the D product 5g is mixed with the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com