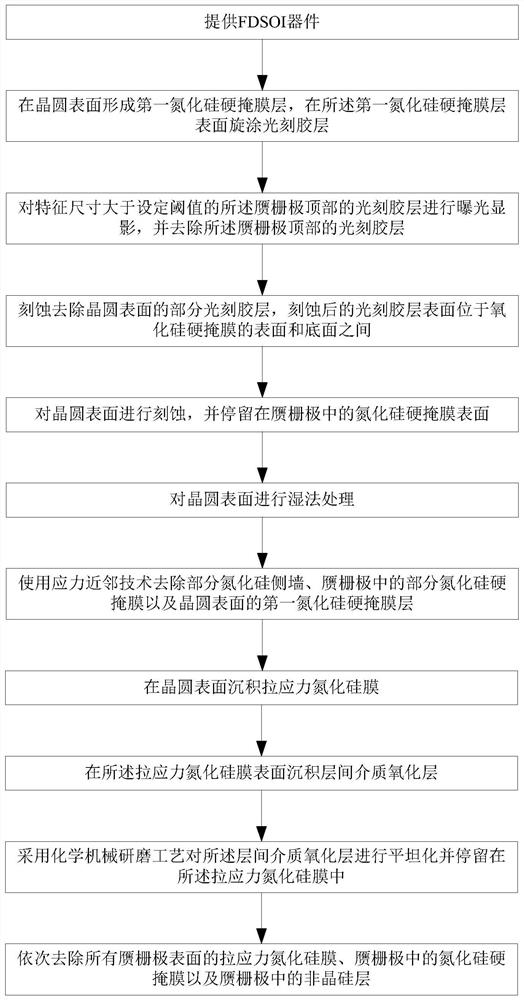

Pseudo-gate removal method for fdsoi devices

A pseudo-gate and device technology, which is applied in the field of pseudo-gate removal of FDSOI devices, can solve the problems of large difference and damaged gate height, and achieve the effects of small gate height difference, reduced damage, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

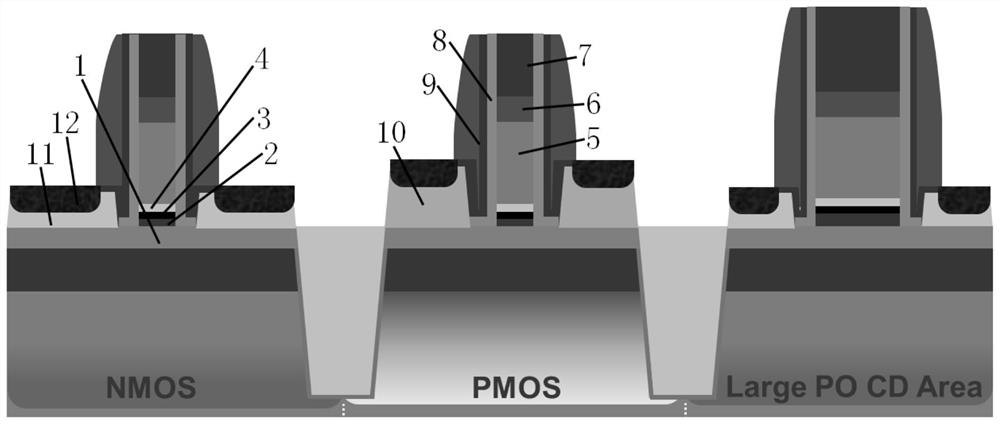

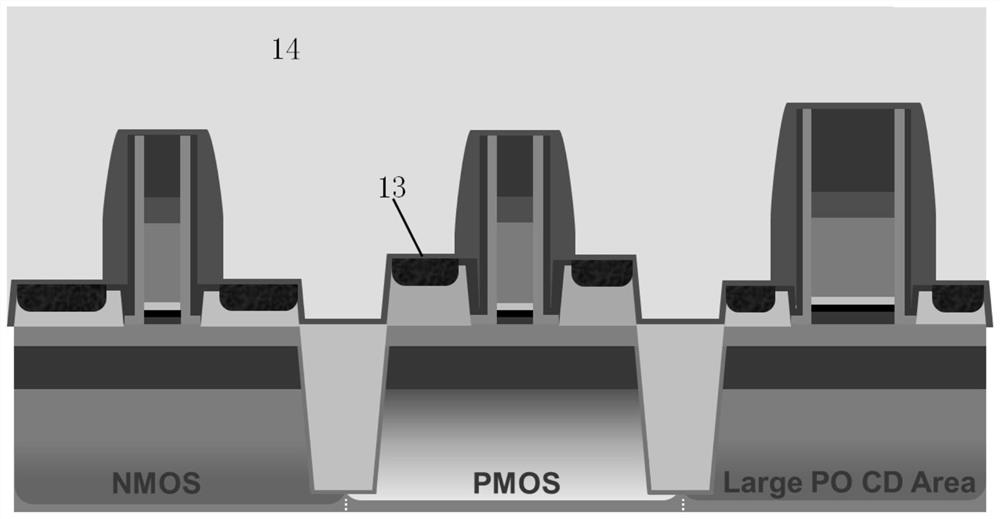

[0051] In the current traditional gate-last HKMG process, phosphoric acid will damage the source-drain SiGe layer of PMOS when using phosphoric acid to wet-process the silicon nitride sidewall, and the interlayer dielectric layer is planarized by chemical mechanical polishing process. At the same time, the pseudo gate will be directly opened, and the chemical mechanical polishing process will introduce differences between different wafers, between different batches and different pattern densities, resulting in large differences in the final gate height.

[0052] To this end, the present invention proposes a pseudo gate removal method. First, part of the stress proximity technology (SPT) plasma etching is used to remove part of the silicon nitride sidewall spacer, and a small amount of bias power is appropriately used during the plasma etching. To achieve anisotropic etching, the silicon nitride spacers are partially removed and the loss of the silicon nitride hard mask on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com