Sintering-resistant mosaic Pd@cerium dioxide nanotube catalyst and preparation method thereof

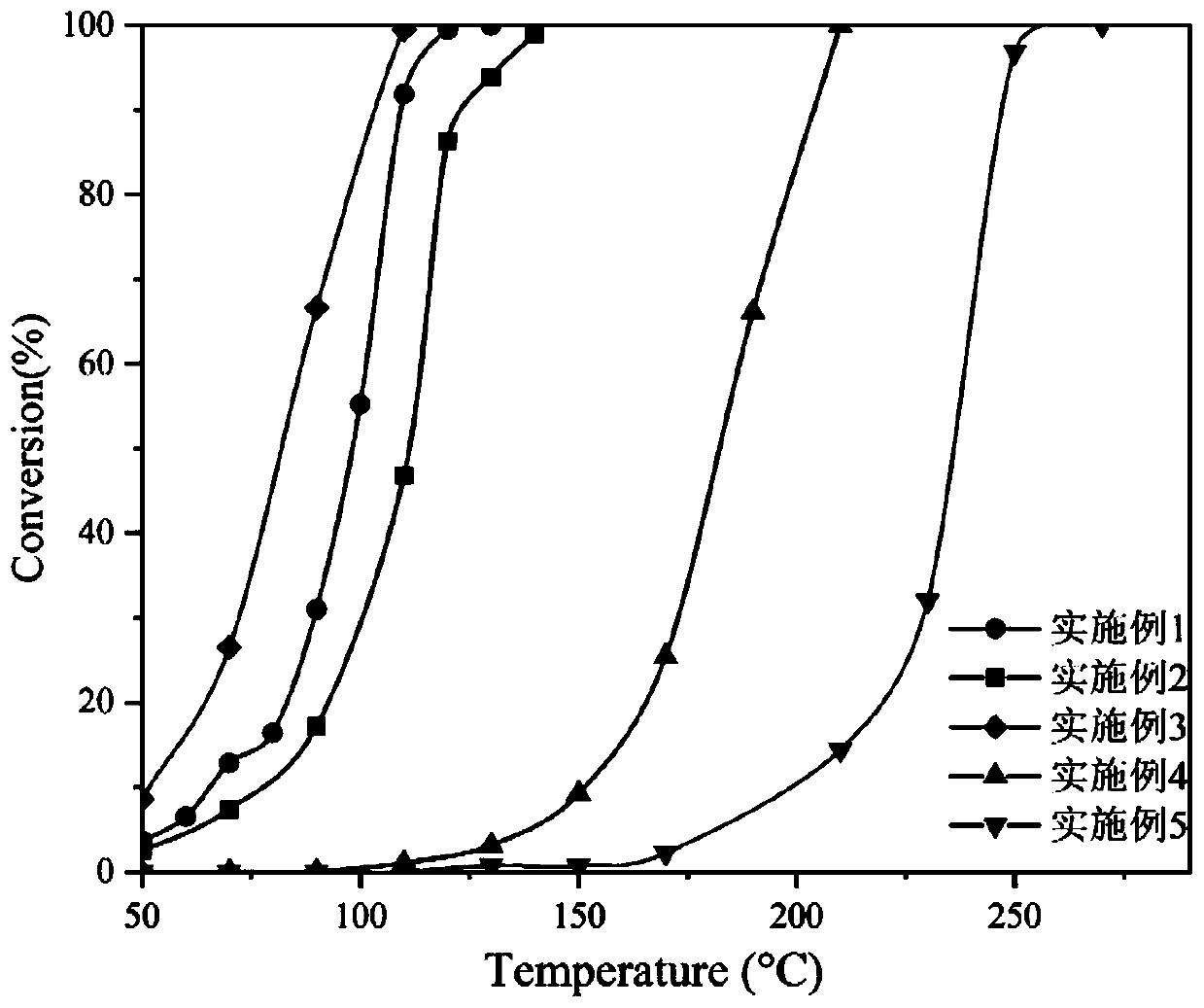

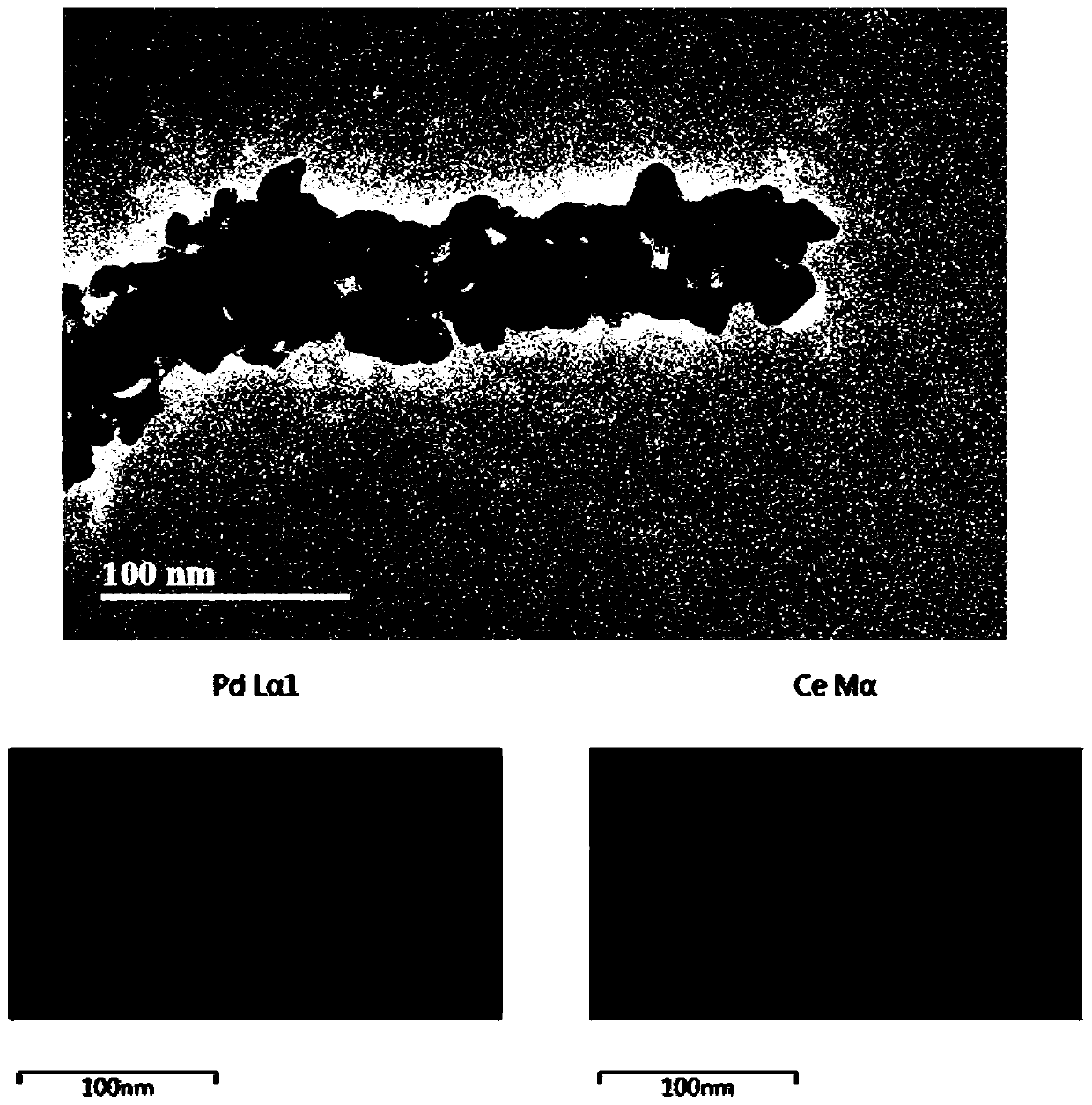

A technology of ceria and nanotubes, which is applied in the field of mosaic Pd@CeO2 nanotube catalysts and their preparation, can solve the problems of catalyst incapability of industrial production, deactivation, and deterioration of catalyst reactivity, and achieve good carbon monoxide oxidation activity and stability performance, anti-sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dissolve 0.2g of PVP in a mixed solvent of ethanol (14ml) and water (21ml), and add 24mL of chloropalladium acid solution (2.0mM) after complete dissolution. After stirring and refluxing at 110° C. for 3 h, the solvent was evaporated to dryness by a rotary evaporator to obtain a dark brown PVP-Pd colloid.

[0023] (2) Dissolve the PVP-Pd colloid in 50 mL of ethanol, and add 0.50 g of carbon nanotubes with a diameter in the range of 30-50 nm. Stirring at 40°C for 24h, evaporating the solvent to dryness, and calcining at 300°C for 60min to obtain Pd / CNT.

[0024] (3) Add 1.26g of cerous nitrate to 50mL of ethylene glycol, stir vigorously to form a transparent homogeneous solution, add Pd / CNT, mix the solution evenly after ultrasonication for 60min, transfer it to the reaction kettle, and obtain after hydrothermal reaction at 200℃ for 24h Yellow-brown colloid mixed with black particles. Centrifuged, washed five times with deionized water, washed once with ethanol, an...

Embodiment 2

[0027] (1) Dissolve 0.2g PVP in the mixed solvent of ethanol (14ml) and water (21ml), after completely dissolving

[0028] 24 mL of chloropalladic acid solution (2.0 mM) was added. Stir and reflux at 110° C. for 3 h, and evaporate the solvent to dryness by a rotary evaporator to obtain a dark brown PVP-Pd colloid.

[0029] (2) Dissolve the PVP-Pd colloid in 50 mL of ethanol, and add 0.35 g of carbon nanotubes with a diameter in the range of 30-50 nm. Stir at 40°C for 20h, evaporate the solvent to dryness, and bake at 300°C for 50min to obtain Pd / CNT.

[0030] (3) Add 1.26g of cerous nitrate to 50mL of ethylene glycol, stir vigorously to form a transparent and uniform solution, add Pd / CNT, mix the solution evenly after ultrasonication for 50min, transfer it to the reaction kettle, and obtain after hydrothermal reaction at 200℃ for 24h Yellow-brown colloid mixed with black particles. Centrifuged, washed five times with deionized water, washed once with ethanol, and dried at 6...

Embodiment 3

[0033](1) Dissolve 0.2g of PVP in a mixed solvent of ethanol (14ml) and water (21ml), and add 24mL of chloropalladium acid solution (2.0mM) after complete dissolution. Stir and reflux at 110° C. for 3 h, and evaporate the solvent to dryness by a rotary evaporator to obtain a dark brown PVP-Pd colloid.

[0034] (2) Dissolve the PVP-Pd colloid in 50 mL of ethanol, and add 0.29 g of carbon nanotubes with a diameter in the range of 30-50 nm. Stir at 40°C for 16h, evaporate the solvent to dryness, and bake at 300°C for 40min to obtain Pd / CNT.

[0035] (3) Add 1.26g of cerous nitrate to 50mL of ethylene glycol, stir vigorously to form a transparent homogeneous solution, add Pd / CNT, mix the solution evenly after ultrasonication for 40min, transfer it to the reaction kettle, and react hydrothermally at 200℃ for 24h to obtain Yellow-brown colloid mixed with black particles. Centrifuged, washed five times with deionized water, washed once with ethanol, and dried at 60°C to obtain a pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com