Zr-MOF modified ZnCdS nano microsphere composite material and application thereof

A technology of nano-microspheres and composite materials, which can be used in organic compound/hydride/coordination complex catalysts, inorganic chemistry, hydrogen and other directions, which can solve application limitations, large band gaps, and photocatalytic activity of photocatalysts that cannot meet basic requirements. and other problems, to achieve the effects of multiple active sites, excellent hydrogen production performance, and good recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Dissolve 1 mmol of zirconium chloride and 1 mmol of terephthalic acid in 30 mL of DMF and sonicate until complete

[0031] After completely dissolving, transfer it to a 50 mL polytetrafluoroethylene reactor liner, cover and seal it, put it in an oven, heat at 120 °C for 24 h, and after cooling down to room temperature, the product is washed several times with DMF and methanol respectively, and the After vacuum drying at 80 ℃, the metal-organic framework Zr-MOF was obtained, which was named UIO-66(Zr).

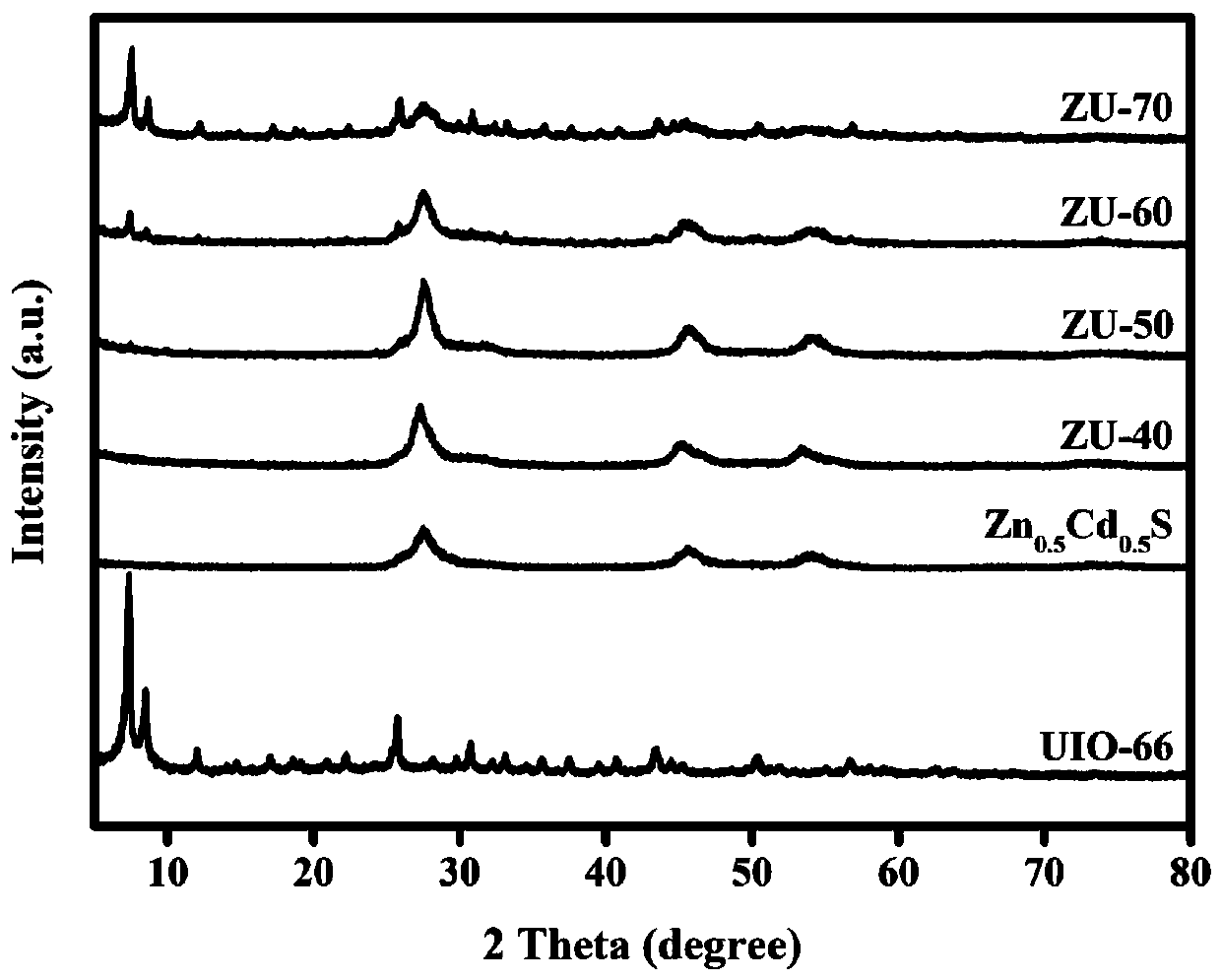

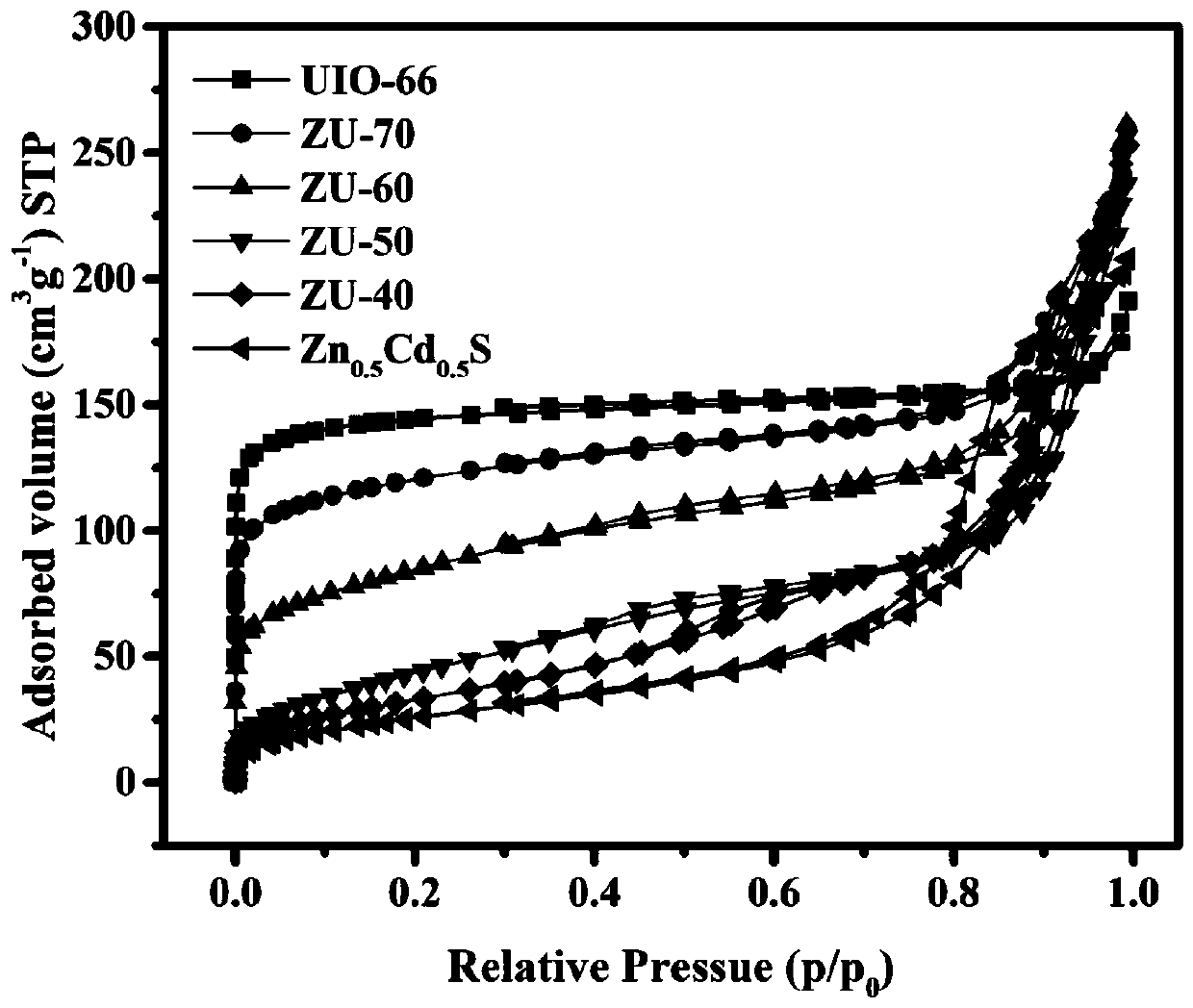

[0032]2) Weigh 80.7 mg, 121 mg, 181.5 mg, 282.3 mg of UIO-66(Zr) obtained in step (1) into four beakers (representing the moles of UIO-66(Zr) added to the composite material 40%, 50%, 60%, 70%), add 5mL of water, ultrasonic treatment to obtain uniformly dispersed suspensions A1, A2, A3, A4, take four other beakers, respectively weigh 0.5 mmol cadmium acetate and 0.5 Mmol zinc acetate, measure 15 mL of water, stir for 30 min until uniformly dispersed to obtain suspens...

Embodiment 2

[0038] 1) The composite material catalyst obtained in Example 1 is subjected to photocatalytic hydrogen production with visible light.

[0039] 2) Under the irradiation of visible light, the hydrogen production experiment was carried out in a closed quartz reaction system. The temperature of the reaction system was kept at 6 °C by cooling circulating water, and 50 mg of catalyst was dispersed in an aqueous solution of 0.25 M sodium sulfide and 0.35 M sodium sulfite ( 80mL), in which sodium sulfide and sodium sulfite were used as sacrificial agents, the air was completely removed under continuous stirring, and a 300W Xe arc lamp with a 420nm filter (CEL-HXF300) was used as a light source, and online gas chromatography (FULI, GC -7920) for hydrogen evolution analysis. After the light starts, samples are taken every 1 hour to get Figure 5 The hydrogen production histogram is shown. It can be concluded that when the weight of UIO-66(Zr) is added to 50%, the hydrogen production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com