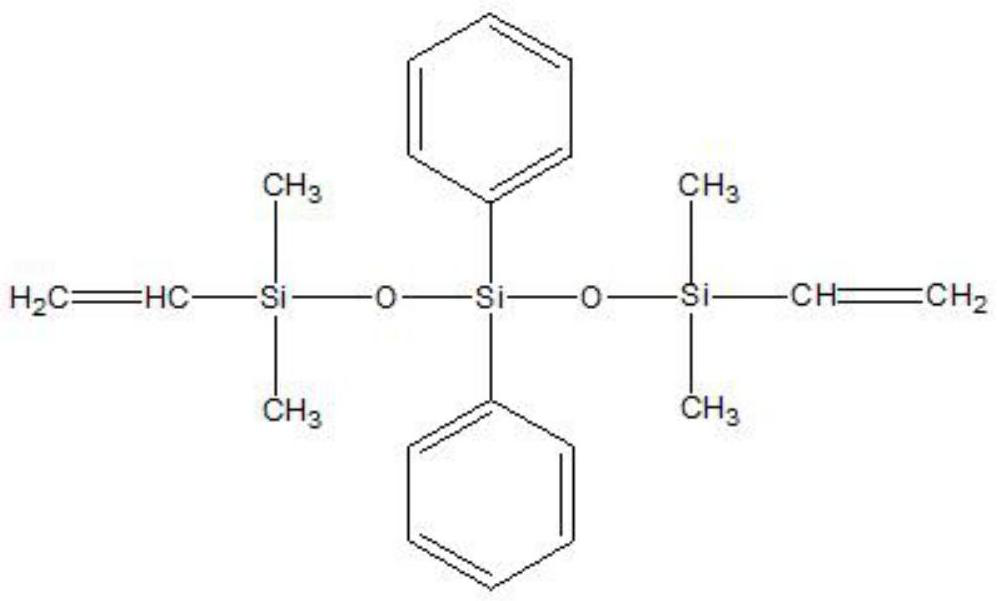

A kind of preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane

A technology of divinyltetramethyldisiloxane and tetramethyltrisiloxane, which is applied in the field of synthesis of organosilicon compounds, and achieves the effects of high yield, high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

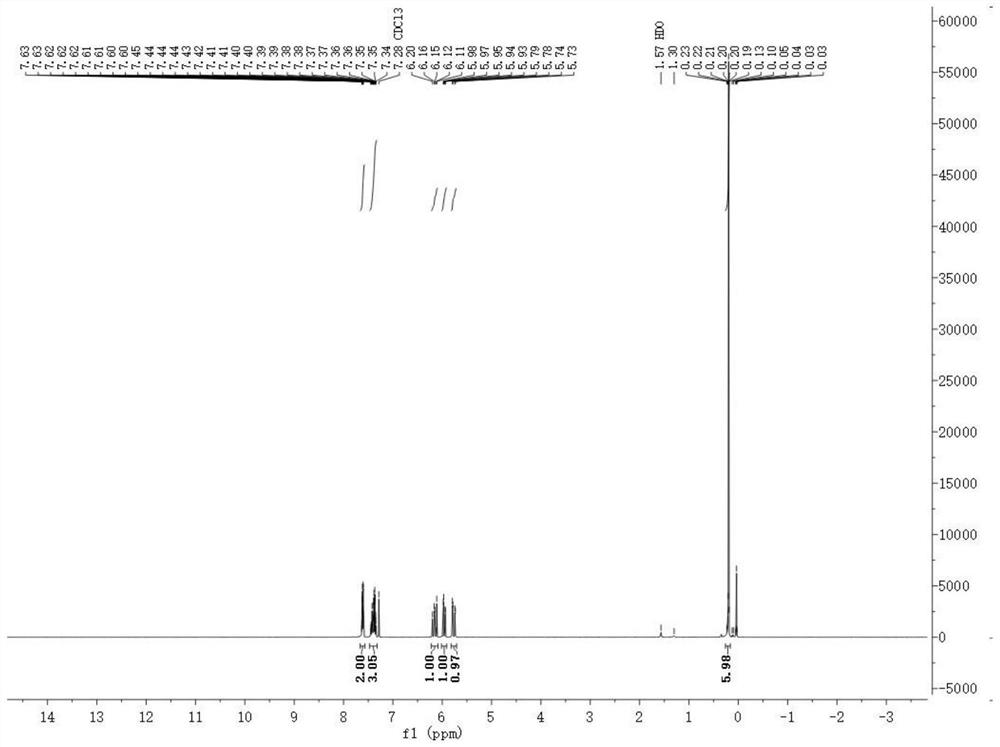

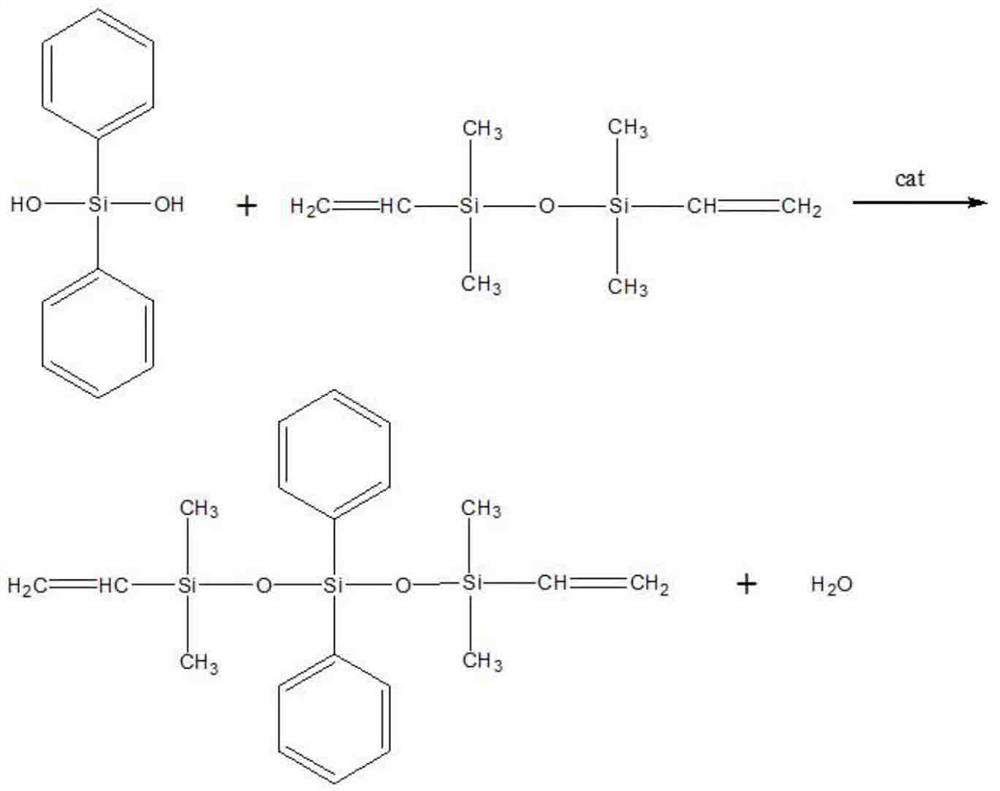

[0039] A preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane, comprising the steps of:

[0040] (1) Under nitrogen protection, add 216g (1.0mol) diphenylsilanediol, 204.6g (1.1mol) divinyl Tetramethyldisiloxane and 409.2g n-hexane, then slowly add 4.2g p-toluenesulfonic acid to it and stir to form milky white suspension;

[0041] (2) Turn on the heating, and slowly raise the temperature of the suspension to 70-80°C for reflux reaction. During the reaction, use a water separator to reflux and separate the water generated by the reaction. As the reaction progresses, the system gradually changes from milky white to clear and transparent. Maintain the reaction for 2h;

[0042] (3) After the reaction is complete, the system is lowered to room temperature, and 5% aqueous sodium bicarbonate solution is added to the flask to neutralize the catalyst, then the layers are left to stand, and the organic phase is washed with water at 50-60°C for 0.5h until The s...

Embodiment 2

[0046] A preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane, comprising the steps of:

[0047] (1) Under nitrogen protection, add 216g (1.0mol) diphenylsilanediol, 204.6g (1.1mol) divinyl Tetramethyldisiloxane and 409.2g n-hexane, then slowly add 8.4g p-toluenesulfonic acid therein and stir to form milky white suspension;

[0048] (2) Turn on the heating, and slowly raise the temperature of the suspension to 70-80°C for reflux reaction. During the reaction, use a water separator to reflux and separate the water generated by the reaction. As the reaction progresses, the system gradually changes from milky white to clear and transparent. Maintain the reaction for 2h;

[0049] (3) After the reaction is complete, the system is lowered to room temperature, and 5% aqueous sodium carbonate solution is added to the flask to neutralize the catalyst. Become neutral, obtain upper layer organic phase crude product;

[0050] (4) Collect the organic phase, carry ...

Embodiment 3

[0052] A preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane, comprising the steps of:

[0053] (1) Under nitrogen protection, add 216g (1.0mol) diphenylsilanediol, 204.6g (1.1mol) divinyl Tetramethyldisiloxane and 511.5g n-hexane, then slowly add 12.6g p-toluenesulfonic acid to it and stir to form milky white suspension;

[0054] (2) Turn on the heating, and slowly raise the temperature of the suspension to 70-80°C for reflux reaction. During the reaction, use a water separator to reflux and separate the water generated by the reaction. As the reaction progresses, the system gradually changes from milky white to clear and transparent. Maintain the reaction for 2h;

[0055] (3) After the reaction is complete, the system is lowered to room temperature, and 5% potassium bicarbonate aqueous solution is added to the flask to neutralize the catalyst, then the layers are left to stand, and the organic phase is washed with water at 50-60°C for 0.5h until T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com