A kind of shape memory phenolic resin and preparation method thereof

A technology of phenolic resin and resole phenolic resin, which is applied in the field of shape memory phenolic resin and its preparation, can solve the problems of high brittleness, poor deformation resistance, restricting the development of phenolic resin, etc., and achieves improved toughness and fast shape recovery rate. , the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

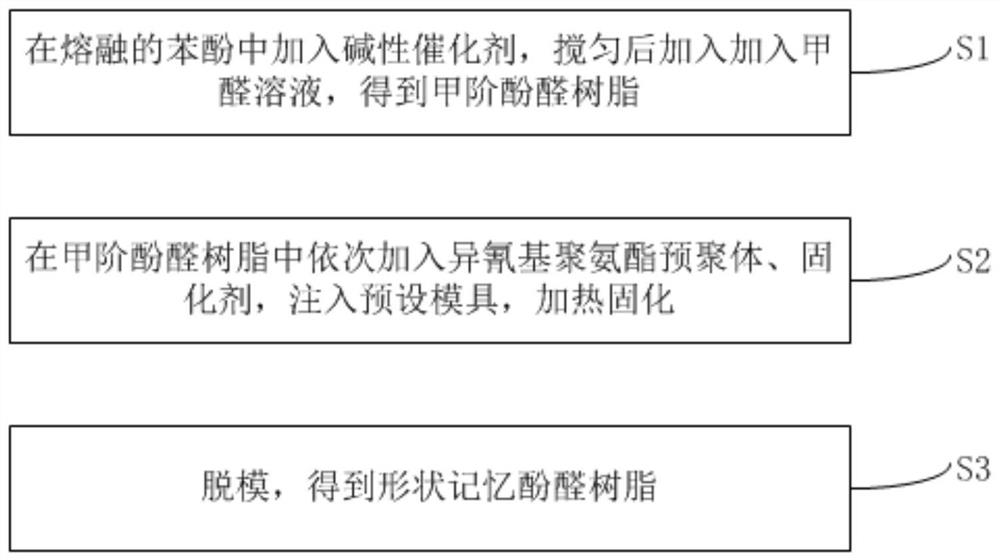

[0043] The preparation method of above-mentioned shape memory phenolic resin, comprises the following steps:

[0044] S1, adding a basic catalyst to the molten phenolic compound, stirring evenly, then adding an aldehyde compound, heating and condensing to reflux, and finally vacuuming and dehydrating to obtain a resole phenolic resin;

[0045] S2. Add isocyanopolyurethane prepolymer and curing agent to the resole phenolic resin in sequence, stir evenly, and inject the mixture into a preset mold, heat and solidify in a vacuum heating furnace;

[0046] S3, cooling to room temperature and demoulding to obtain the shape memory phenolic resin.

[0047] Specifically, in step S1, taking the phenolic compound as phenol and the aldehyde compound as formaldehyde as an example, the chemical reaction formula of the reaction is:

[0048]

[0049] In step S1, the basic catalyst includes: one or more of ammonia water, sodium hydroxide, barium hydroxide or aluminum hydroxide. Wherein, th...

Embodiment 1

[0064] This example provides a kind of preparation method of shape memory phenolic resin, specifically carries out according to the following steps:

[0065] 1) Take melted phenol, add it to a three-necked flask, preheat and stir in an oil bath at 55°C; drop ammonia water into the three-necked flask, the molar ratio of ammonia water and phenol is 0.05:1, and heat it at 55°C Stir for 5 minutes; then slowly add formaldehyde solution to the three-necked flask, the molar ratio of formaldehyde solution and phenol is 1:1.6, continue to stir, then raise the temperature to 70°C, keep it warm for 30 minutes, then raise the temperature to 98°C to condense and reflux for 30 minutes, and finally cool naturally Lower the temperature to below 70°C, and vacuum dehydrate to obtain the resole phenolic resin.

[0066] 2) Take 100 parts of resole phenolic resin prepared in step 1), and mix 5 parts of isocyanopolyurethane prepolymer evenly. After stirring for 30 minutes, add 2 parts of curing age...

Embodiment 2

[0068] The difference between this example and the above-mentioned examples is that the preparation method of a shape memory phenolic resin provided in this example is specifically carried out according to the following steps:

[0069] 1) Take melted phenol, add it to a three-necked flask, preheat and stir in an oil bath at 55°C; drop ammonia water into the three-necked flask, the molar ratio of ammonia water and phenol is 0.05:1, and heat it at 55°C Stir at low temperature for 5 minutes; then slowly add formaldehyde solution to the three-necked flask, the molar ratio of formaldehyde solution and phenol is 1:2, continue to stir, then raise the temperature to 70°C, keep it warm for 30 minutes, then raise the temperature to 98°C to condense and reflux for 30 minutes, and finally cool naturally Lower the temperature to below 70°C, and vacuum dehydrate to obtain the resole phenolic resin.

[0070] 2) Take 100 parts of resole phenolic resin prepared in step 1), and mix 5 parts of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com