A kind of phosphorus-containing acrylate elastomer flame retardant and preparation method thereof

A technology of acrylate and methyl acrylate, applied in the field of phosphorous-containing acrylate elastomer flame retardant and its preparation, and can solve problems such as poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of (diethoxyphosphine) methyl acrylate (DEAMP)

[0028] (1) Add 16.8 g (0.1 mol) of diethyl hydroxymethylphosphonate, 10.1 g (0.1 mol) of dichloromethane (50 mL) and 10.1 g (0.1 mol) of triethylamine into a 250 mL three-necked flask, and place in an ice-salt bath at -5°C React under stirring for 0.5h;

[0029] (2) Mix 9g (0.1mol) of acryloyl chloride and 10mL of dichloromethane evenly and slowly drop them into a three-necked flask. 12h;

[0030] (3) washing with water after the reaction is finished, and rotary evaporation to remove triethylamine salt and unreacted monomers and solvents to obtain an orange-yellow liquid;

[0031] (4) Use ethyl acetate as the mobile phase, purify by neutral silica gel column chromatography, remove ethyl acetate by rotary evaporation at 40-60°C, and finally obtain light yellow (diethoxyphosphine) methyl acrylate (DEAMP) .

Embodiment 2

[0033] Preparation method of phosphorus-containing acrylate elastomer flame retardant

[0034] (1) Mix 20g DEAMP, 0.3g sodium dodecyl sulfate (SDS), 0.3g p-styrene sulfonate (SSS) and 30mL deionized water prepared in Example 1, and carry out at a stirring speed of 600rpm Pre-emulsify for 0.5h.

[0035] (2) Add 20% pre-emulsion, 0.3g SDS, 0.3g SSS, 0.04g potassium persulfate (KPS) and 20mL deionized water into a 150ml four-neck flask, heat it to 78°C in a constant temperature water bath, and keep the speed 150rpm.

[0036] (3) After the blue light appears in the bottle, start to add the remaining pre-emulsion dropwise. After the dropwise addition is completed and react for 4 hours, cool down and discharge, break the emulsion, filter, wash with deionized water for many times, and dry to finally obtain a white phosphorus-containing acrylate elastomer. flame retardant.

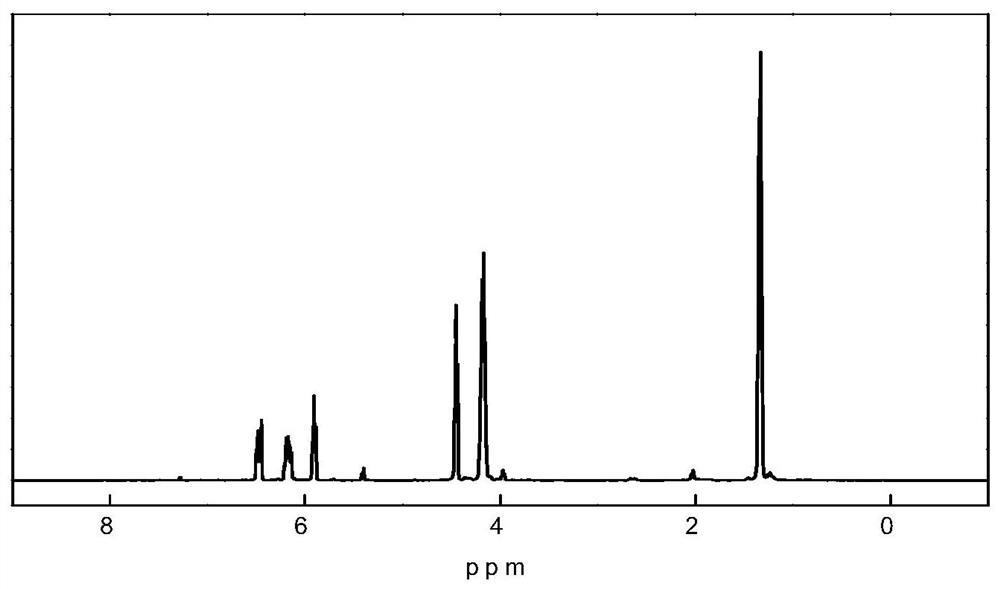

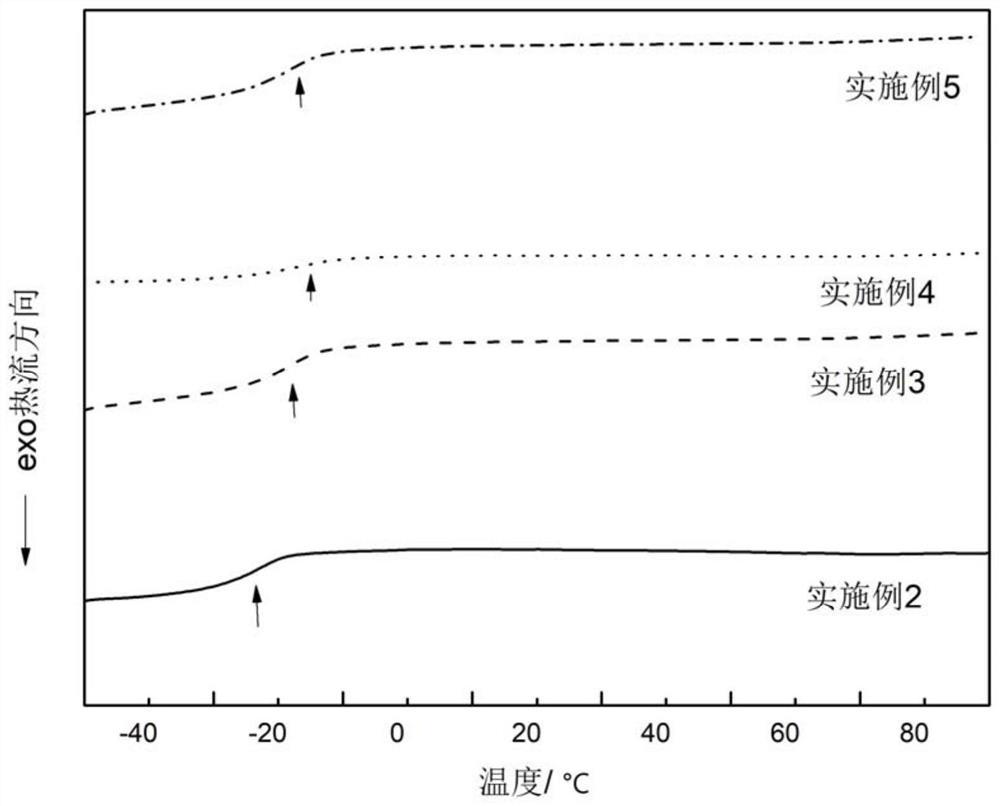

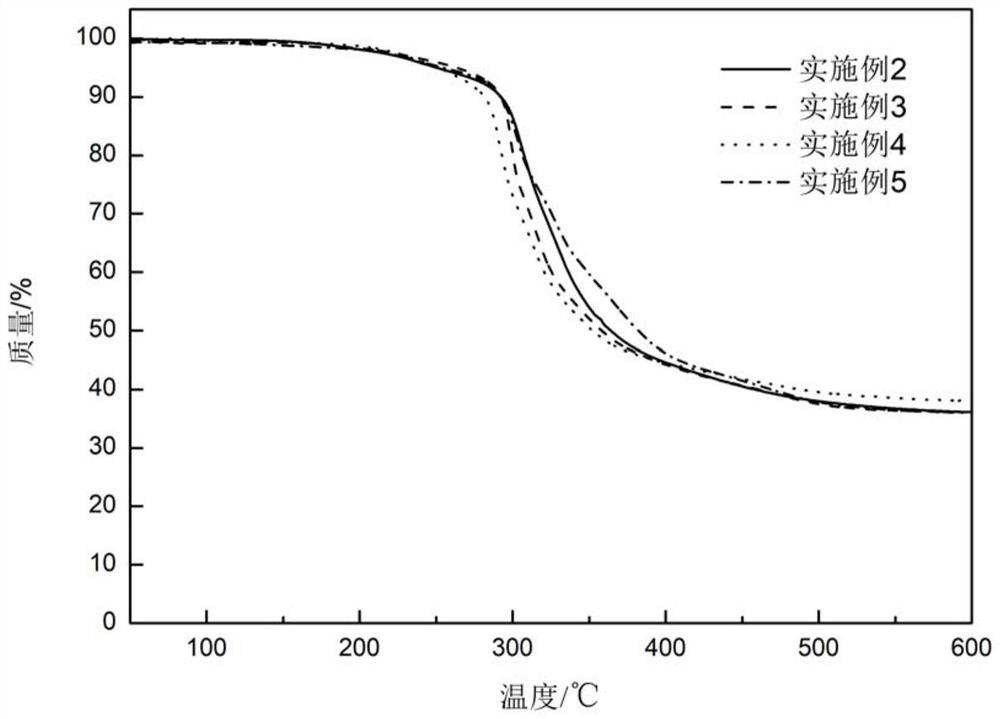

[0037] Depend on figure 2 It can be seen that the phosphorus-containing acrylate elastomer flame retardant...

Embodiment 3

[0040] Preparation method of phosphorus-containing acrylate elastomer flame retardant

[0041] (1) Mix 20g DEAMP, 0.2g TAIC, 0.3g SDS, 0.3g SSS and 30mL deionized water prepared in Example 1, and perform pre-emulsification at a stirring speed of 600rpm.

[0042] (2) Then add 20% pre-emulsion, 0.3g SDS, 0.3g SSS, 0.04g KPS and 20mL deionized water into a 150ml four-neck flask, heat it to 78°C in a constant temperature water bath, and keep the rotation speed at 150rpm.

[0043] (3) After the reaction, when the blue light appeared in the bottle, start to add the remaining pre-emulsion dropwise, add the remaining monomer pre-emulsion dropwise, react for 4 hours after the dropwise addition, cool down and discharge the material, break the emulsion, filter, wash and dry with deionized water for many times, Finally, a white phosphorus-containing acrylate elastomer flame retardant is obtained.

[0044] Depend on figure 2 It can be seen that the phosphorus-containing acrylate elastom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com