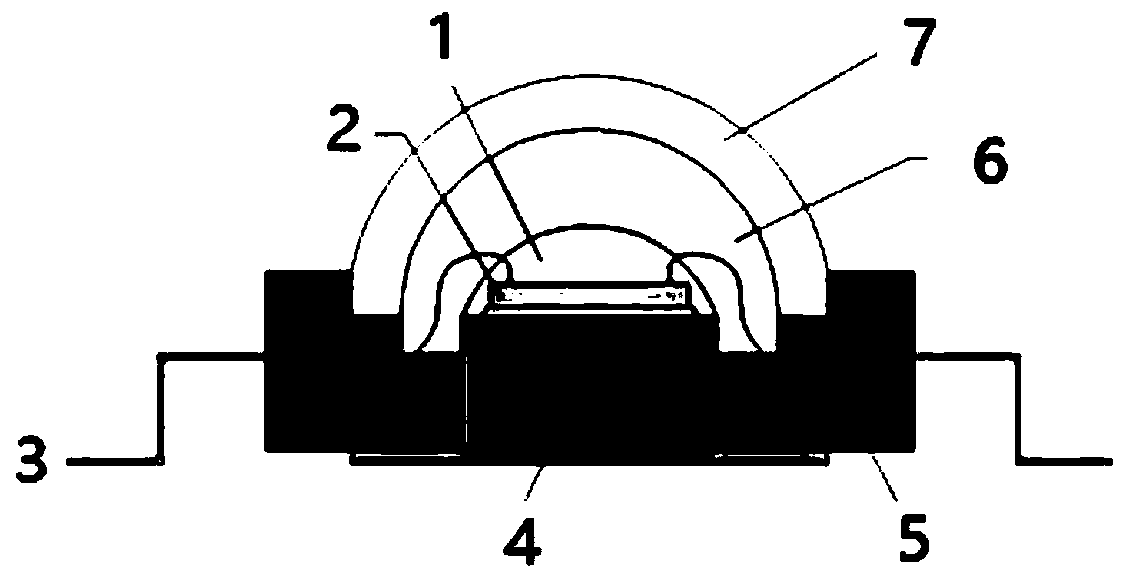

Near-infrared light-emitting material and light-emitting device comprising light-emitting material

A technology of light-emitting materials and light-emitting devices, applied in the directions of light-emitting materials, electrical components, circuits, etc., can solve the problems of low light-emitting efficiency and poor stability, and achieve the effects of high light-emitting efficiency, low cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

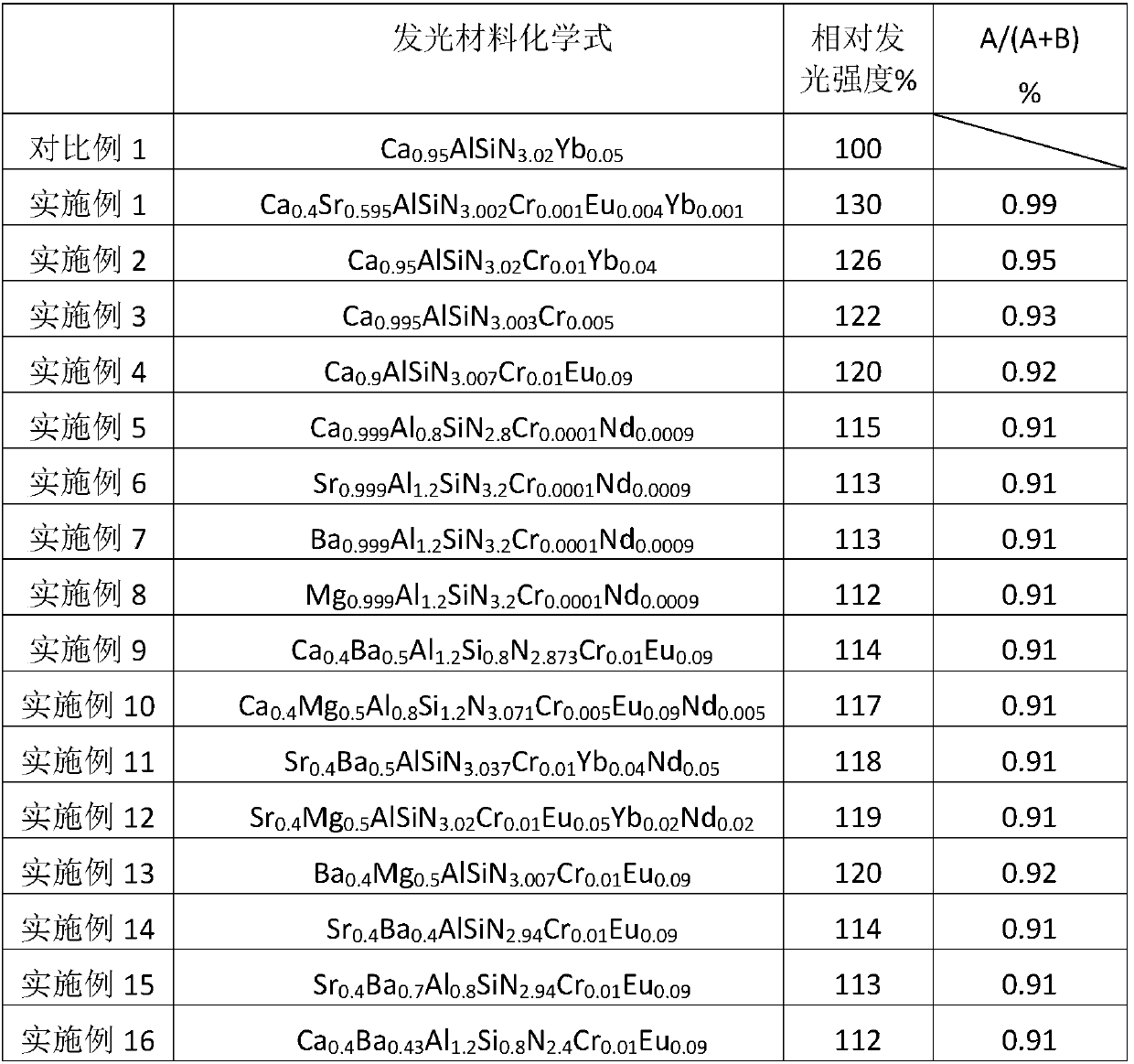

Embodiment 1

[0035] A near-infrared luminescent material whose chemical formula is Ca 0.4 Sr 0.595 AlSiN 3.002 Cr 0.001 Eu 0.004 Yb 0.001 , according to its stoichiometric ratio, accurately weigh Ca 3 N 2 (99.9%), AlN (99.9%), Si 3 N 4 (99.9%), CrO 2 (99.99%), Yb 2 o 3 (99.99%), Sr 2 N (99.9%), EuN (99.9%) raw material. A total of 100 g of the above raw materials were placed in a mortar and mixed evenly in a glove box (oxygen content < 1 ppm, water content < 1 ppm). The mortar was made of agate or alumina ceramics. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature atmosphere furnace. The high-temperature atmosphere furnace starts to heat up after being vacuumed and filled with nitrogen, and the heating rate is 10°C / min. , nitrogen pressure is 3MPa. Heat up to 1900°C and keep warm for 20 hours. After the keep warm, turn off the power and cool down with the furnace. Take out the fired sample, grin...

Embodiment 2

[0037] A near-infrared luminescent material whose chemical formula is Ca 0.95 AlSiN 3.02 Cr 0.01 Yb 0.04 , according to its stoichiometric ratio, accurately weigh Ca 3 N 2 (99.9%), AlN (99.9%), Si 3 N 4 (99.9%), CrO 2 (99.99%), Yb 2 o 3 (99.99%) Raw. A total of 100 g of the above raw materials were placed in a mortar and mixed evenly in a glove box (oxygen content < 1 ppm, water content < 1 ppm). The mortar was made of agate or alumina ceramics. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature atmosphere furnace. The high-temperature atmosphere furnace starts to heat up after being vacuumed and filled with nitrogen, and the heating rate is 10°C / min. , nitrogen pressure is 5MPa. Heat up to 1900°C and keep warm for 15 hours. After the keep warm, turn off the power and cool down with the furnace. Take out the fired sample, grind, grind, remove impurities, wash, sieve, and dry to obtain t...

Embodiment 3

[0039] A near-infrared luminescent material whose chemical formula is Ca 0.995 AlSiN 3.003 Cr 0.005 , according to its stoichiometric ratio, accurately weigh Ca 3 N 2 (99.9%), AlN (99.9%), Si 3 N 4 (99.9%), CrO 2 (99.99%) Raw. A total of 100 g of the above raw materials were placed in a mortar and mixed evenly in a glove box (oxygen content < 1 ppm, water content < 1 ppm). The mortar was made of agate or alumina ceramics. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature atmosphere furnace. The high-temperature atmosphere furnace starts to heat up after being vacuumed and filled with nitrogen, and the heating rate is 10°C / min. , nitrogen pressure is 2MPa. Heat up to 1910°C and keep warm for 20 hours. After the keep warm, turn off the power and cool down with the furnace. Take out the fired sample, grind, grind, remove impurities, wash, sieve, and dry to obtain the final sample, then measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com