Construction method of ultra-shallow overburden and large longitudinal slope starting construction method of shield machine in coastal dredging and reclamation stratum

A construction method and shield machine technology, applied in earthwork drilling, underground chambers, shaft equipment, etc., can solve problems such as excessive shield posture deviation, shield machine easy to fall, and excavation surface collapse, etc., to achieve Shield posture is well controlled, avoiding uneven settlement, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

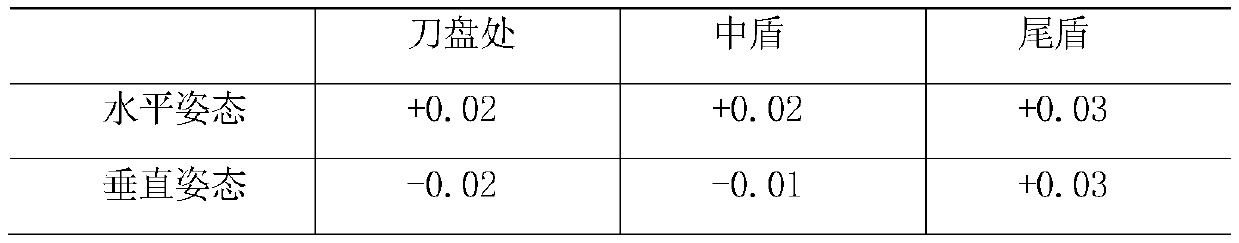

Examples

Embodiment Construction

[0044] Below by embodiment, the present invention will be further described:

[0045] A construction method for ultra-shallow earth-covering and large longitudinal slope origination of a shield machine in coastal dredging and reclamation, mainly including steps (1)-step (1), and each step will be described in detail below.

[0046] (1) Reinforcement of the soil at the starting end: the soil at the starting end is reinforced with high-pressure rotary grouting piles and three-axis stirring piles, so that the anti-buoyancy of the soil at the starting end can meet the disturbance caused by the shallow covering soil of the shield machine The construction sequence requires the construction of three-axis mixing piles after the completion of the construction of the enclosure structure and before the excavation of the foundation pit, and the construction of the high-pressure jet grouting piles after the completion of the construction of the main structure of the station end shaft and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com