Silver-coated silicone rubber particles, conductive paste containing same, and conductive film production method using conductive paste

A technology of silicone rubber particles and manufacturing methods, applied in the direction of cable/conductor manufacturing, conductive layers on insulating carriers, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of reduced conductivity, increased workload, and particle hypertrophy etc. to achieve good electrical conductivity and inhibit coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

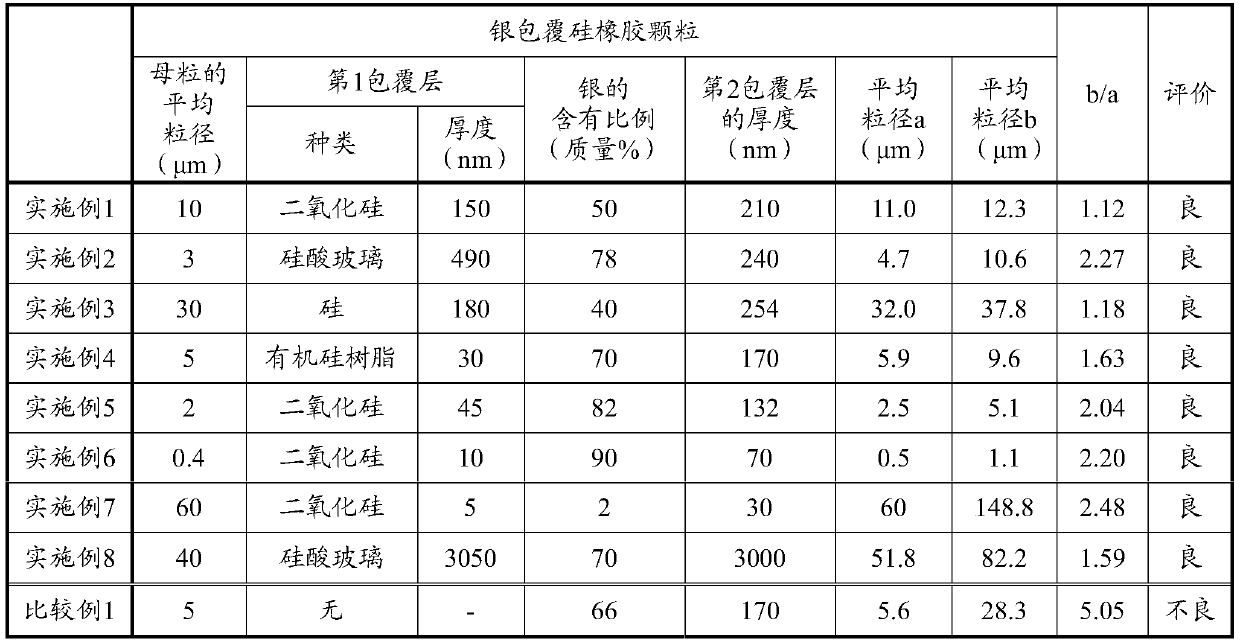

[0050] Next, examples of the present invention will be described in detail together with comparative examples.

[0051]

[0052] First, 10 g of silicone rubber particles having an average particle diameter of 10 μm was prepared as a master batch, and the surface of the silicone rubber particles was modified using an atmospheric plasma device for powder. Next, after immersing the surface-modified silicone rubber particles in 250 g of ion-exchanged water to which a surfactant was added, 25 kHz ultrasonic waves were irradiated for 10 minutes to prepare a dispersion liquid. Then, after adding 550 g of ethanol and 5.0 g of ethyl orthosilicate to this dispersion liquid and stirring for 5 minutes, 5 g of 1% nitric acid was added dropwise to hydrolyze ethyl orthosilicate. As a result, the first coating layer made of silica was provided on the surface of the silicone rubber particles.

[0053] After washing the above-mentioned silicone rubber particles with the first coating layer w...

Embodiment 2

[0055] As the silicone rubber particles with the first coating layer, silicone rubber particles with an average particle diameter of 3 μm of the master batch coated with silicic acid glass are used, and the complexing agent and reducing agent used in the coating of the second layer are used. The mass ratio of the substances contained in the aqueous solution containing silver nitrate and the aqueous solution containing silver nitrate was kept constant, and the mass used was adjusted so that the content ratio of silver became 78 parts by mass relative to 100 parts by mass of silver-coated silicone rubber particles. Except that, silver-coated silicone rubber particles were produced in the same manner as in Example 1. This silver-coated silicone rubber particle is referred to as Example 2. Furthermore, the silicone rubber particles were coated with silicic acid glass by kneading using a combination mixer. Specifically, by using a combination mixer to mechanically knead silicic ac...

Embodiment 3

[0057] As the silicone rubber particles with the first coating layer, silicone rubber particles with an average particle diameter of 30 μm of the master batch coated with silicon were used, and the silicone rubber particles containing a complexing agent and a reducing agent used when coating the second layer were used. The mass ratio of the substances contained in the aqueous solution and the silver nitrate-containing aqueous solution was kept constant, and the mass used was adjusted so that the content ratio of silver became 40 parts by mass relative to 100 parts by mass of silver-coated silicone rubber particles. , Silver-coated silicone rubber particles were produced in the same manner as in Example 1. This silver-coated silicone rubber particle is referred to as Example 3. Furthermore, the silicone rubber particles were coated with silicon by kneading using a combination mixer. Specifically, the silicone rubber with the first coating layer was produced by mechanically kne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com