Preparation method of self-emulsifying glycerol monolaurate

A lauric acid monoglycerol, self-emulsifying technology, applied in the direction of food ingredients as emulsifiers, additional food elements, animal feeds, etc., can solve the problems of inconvenient transportation and use of liquid products, dangers, etc., and is conducive to absorption, utilization and flow. Good sex, not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

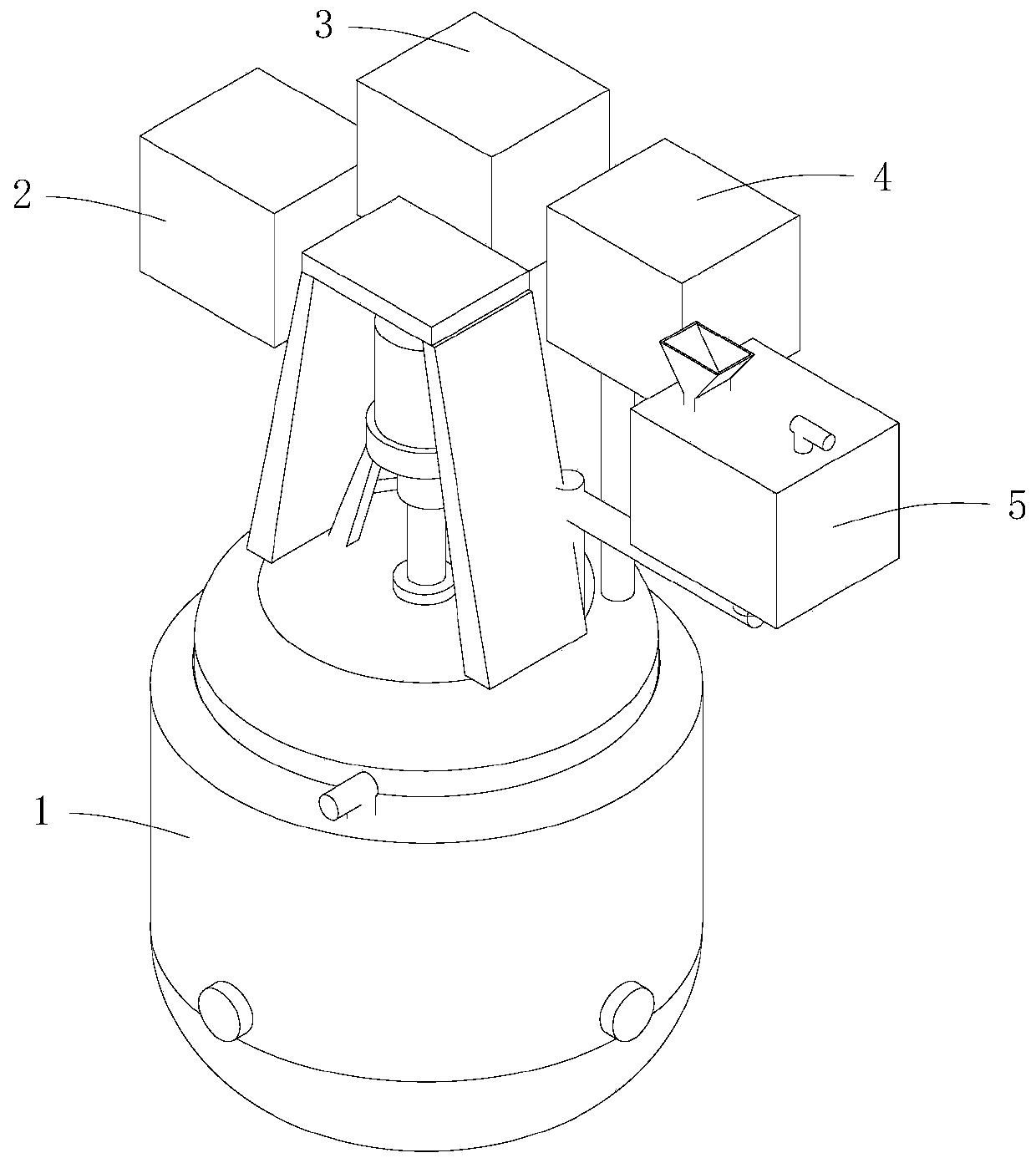

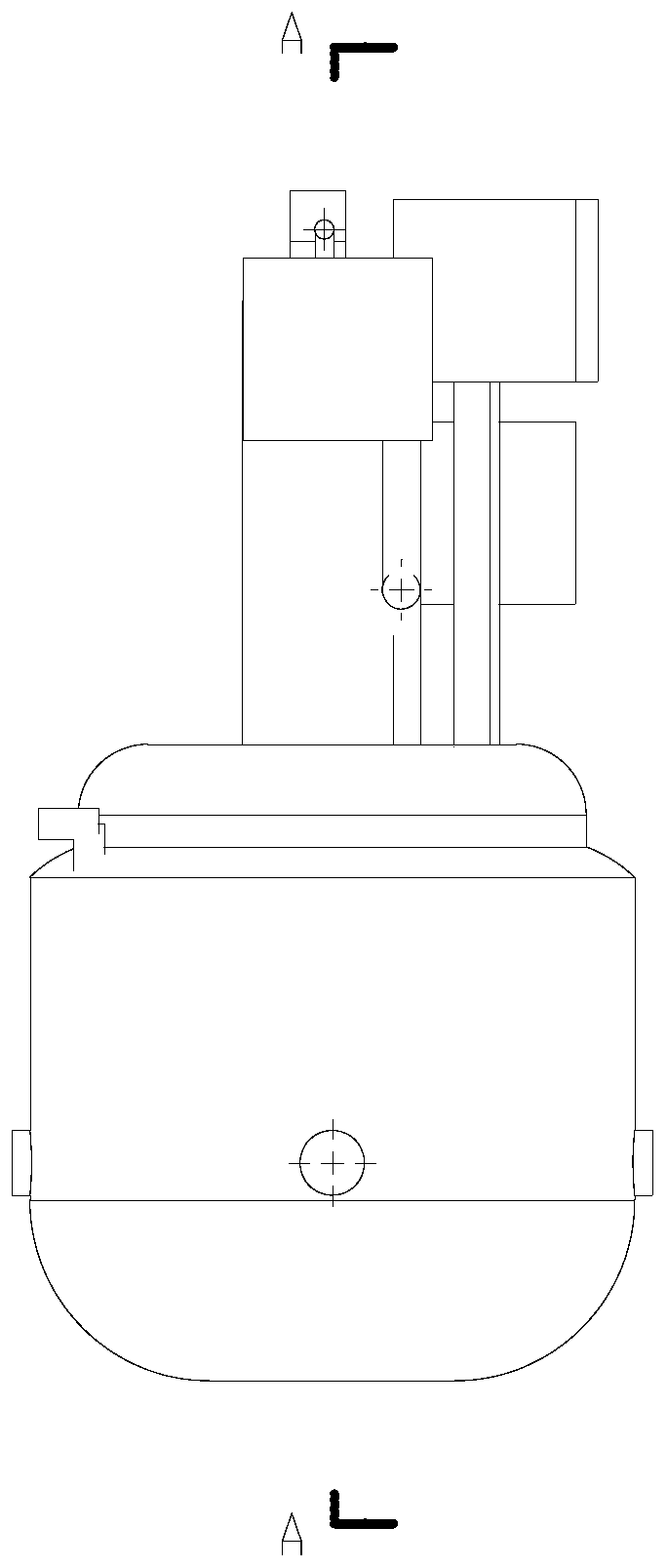

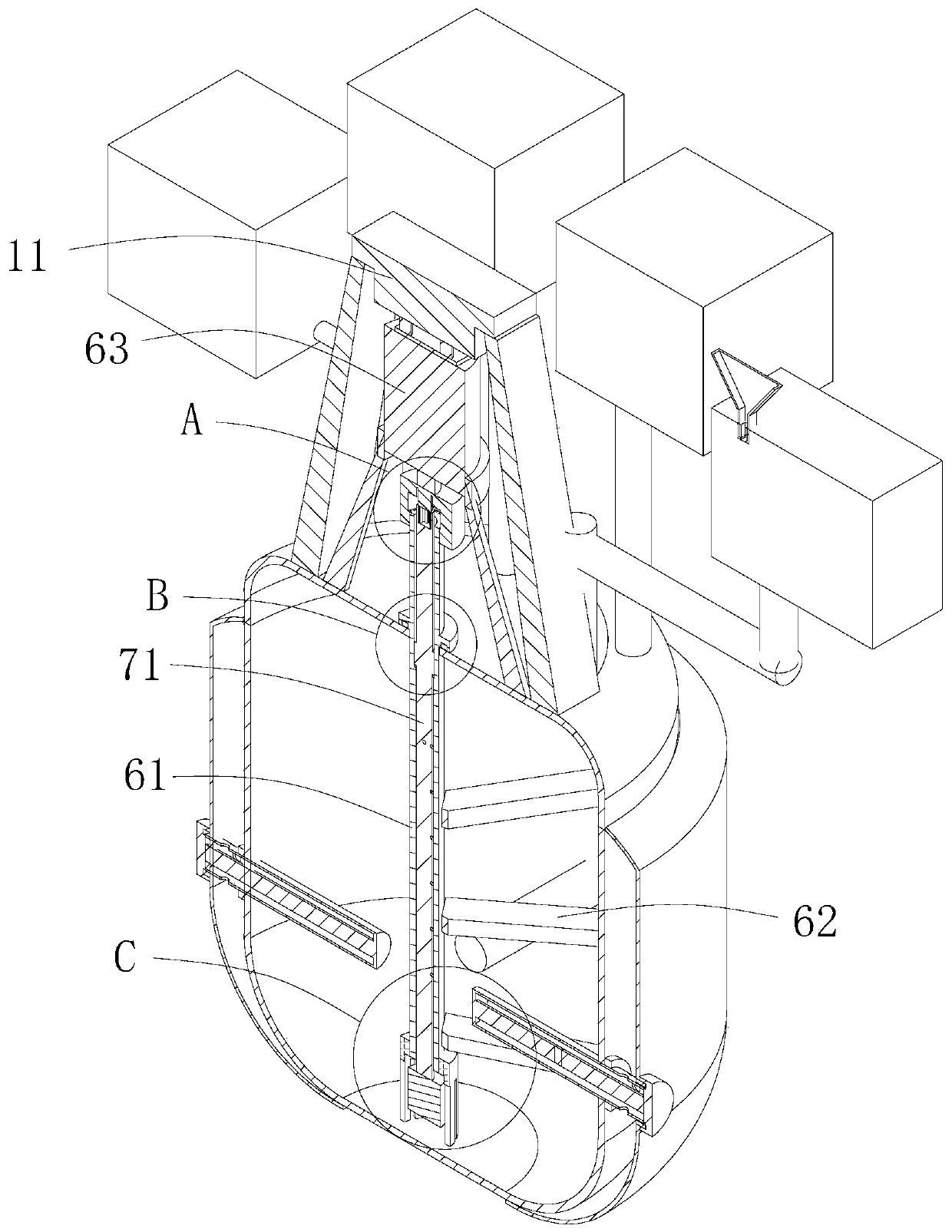

Image

Examples

Embodiment 1

[0032] A kind of preparation method of self-emulsifying laurate monoglyceride, the preparation of described self-emulsification laurate monoglyceride is carried out in reaction system, preparation method comprises the following steps:

[0033] Production of 100kg self-emulsifying monoglyceride laurate,

[0034] a. Take by weighing 48kg of monoglyceride laurate, 10kg of emulsifier (polyglycerol fatty acid ester 7.5kg, glyceryl oleate 2.5kg), solubilizer 4.5kg (Tween 202.5kg, Tween 802kg), emulsification stabilizer 15kg (polyvinyl acetate 5kg, polyvinyl alcohol 6kg, glycerin formal 4kg), water 8kg, sucrose 14.5kg, standby;

[0035] b. Heating the monoglyceride laurate to 60°C to melt, then adding an emulsifier, stirring until dissolved, continuing to add a solubilizer, and homogenizing, the homogenizing pressure is 80MPA, and a clear and transparent oil phase solution is obtained;

[0036] c. Add the emulsification stabilizer into the water, heat to 60°C to dissolve and prepare...

Embodiment 2

[0047] Production of 100kg self-emulsifying monoglyceride laurate,

[0048] a. take by weighing lauric monoglyceride 45kg, emulsifier 7kg (sucrose fatty acid ester 3kg, oleic acid glyceride 4kg), solubilizer 7kg (tween 202.5kg, polyvinylpyrrolidone k304.5kg), emulsification stabilizer 12kg ( Polyvinyl acetate 6kg, polyethylene glycol 400 (6kg), water 7.5kg, maltodextrin 21.5kg, standby;

[0049] b. Heating the monoglyceride laurate to 50°C to melt, then adding an emulsifier, stirring until dissolved, continuing to add a solubilizer, and homogenizing, the homogenizing pressure is 80MPA, and a clear and transparent oil phase solution is obtained;

[0050] c. Add the emulsification stabilizer into the water, heat to 60°C to dissolve and prepare the water phase for later use.

[0051] d. Add the oil phase solution prepared in step b to the water phase solution prepared in step c, mix and stir evenly, perform a second homogenization treatment, homogenization pressure 60MPA, cycle ...

Embodiment 3

[0055] Production of 100kg self-emulsifying monoglyceride laurate,

[0056] a. Take by weighing 50kg of monoglyceride laurate, 10kg of emulsifier (5kg of polyglycerol fatty acid ester, 5kg of sucrose fatty acid ester), 6kg of solubilizer (Tween 20 4kg, Tween 80 2kg), emulsification stabilizer 10kg (polyglycerol fatty acid ester 5kg), Vinyl acetate 6.5kg, glycerin formal 3.5kg), water 9kg, sucrose 10kg, standby;

[0057] b. Heating the monoglyceride laurate to 60°C to melt, then adding an emulsifier, stirring until dissolved, continuing to add a solubilizer for homogenization, the homogenization pressure is 100MPA, and a clear and transparent oil phase solution is obtained;

[0058] c. Add the emulsification stabilizer to the water, heat to 55°C to dissolve and prepare the water phase for later use.

[0059] d. Add the oil phase solution prepared in step b to the water phase solution prepared in step c, mix and stir evenly, perform a second homogenization treatment, the homoge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com