Preparation method of all-inorganic lead-free metal halide perovskite nanowire and high-performance infrared detection application of nanowire

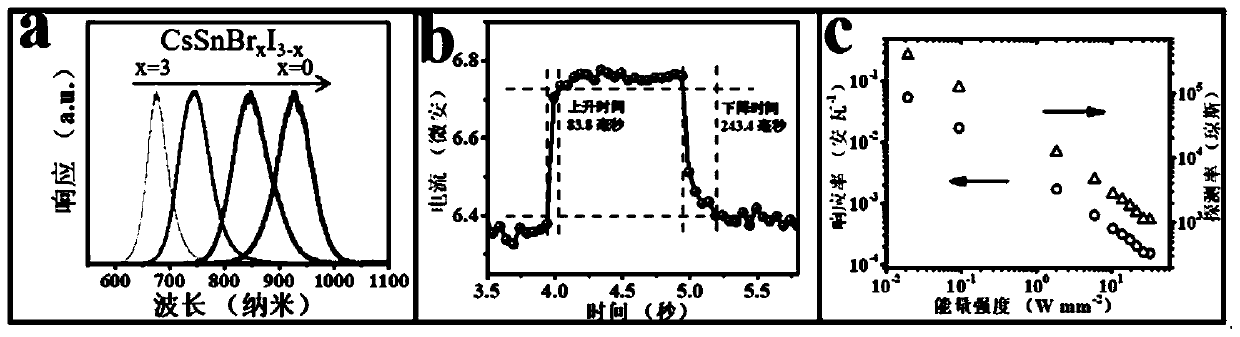

A halide perovskite, lead-free metal technology, applied in the direction of inorganic chemistry, chemical instruments and methods, tin halide, etc., can solve the problems of ineffective response in the infrared band, environmental pollution of perovskite materials, etc., and achieve effective response , Realize the effect of energy band regulation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

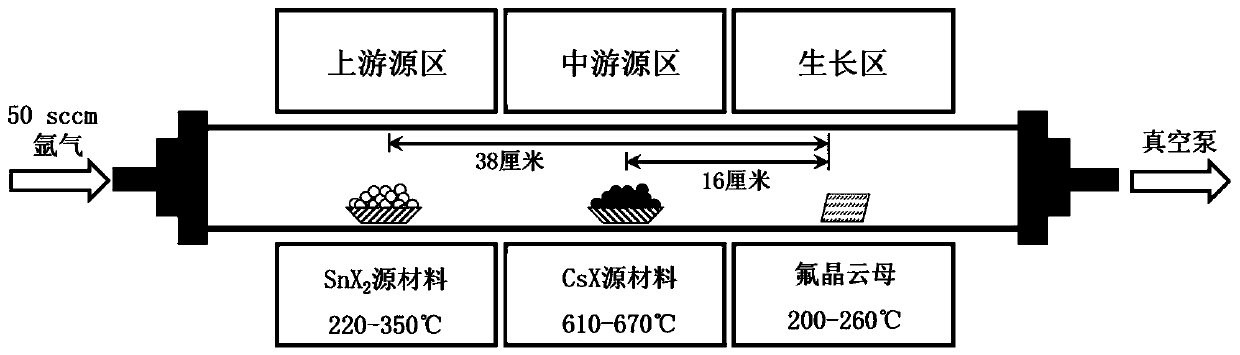

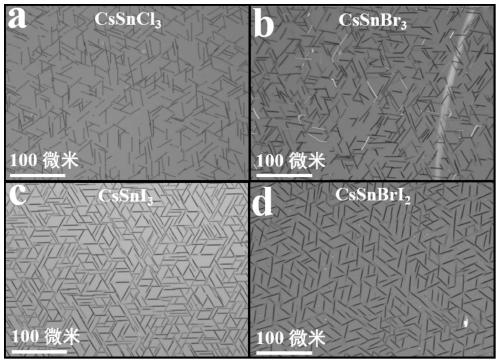

[0051] Using a horizontal tube furnace with three temperature zones, it will contain 0.05g SnI 2 The porcelain boat of particles is placed in the upstream source area, 38cm away from the sample, and the porcelain boat filled with 0.05g CsI powder is placed in the middle reaches of the source area, 16cm away from the sample, and the freshly stripped fluorophlogopite substrate is placed in the middle of the downstream growth area for Nanowire growth. Pump down the pressure of the tube furnace to 10 -3 Torr and Ar for 20 minutes, the gas flow is 50 sccm. Raise the temperature of the growth zone to 210°C for 5 minutes and anneal the SnI 2 The temperature of the CsI source area and the CsI source area were raised to 350° C. and 650° C. respectively, and grown for 20 minutes. After the growth, the source region and the growth region stopped heating at the same time and gradually cooled to room temperature to obtain the nanowire CsSnI 3 .

Embodiment 2

[0053] Using a horizontal tube furnace with three temperature zones, it will contain 0.05g SnI 2 The porcelain boat of particles was placed in the upstream source area, 38cm away from the sample, and the porcelain boat filled with 0.05g CsBr powder was placed in the middle reaches of the source area, 16cm away from the sample, and the freshly peeled fluorophlogopite substrate was placed in the middle of the downstream growth area for Nanowire growth. Pump down the pressure of the tube furnace to 10 -3 Torr and Ar for 20 minutes, the gas flow is 50 sccm. Raise the temperature of the growth zone to 210°C for 5 minutes and anneal the SnI 2 The temperature of the CsBr source area and the CsBr source area were respectively raised to 350° C. and 630° C., and grown for 20 minutes. After the growth, the source region and the growth region stopped heating at the same time and gradually cooled to room temperature to obtain the nanowire CsSnBrI 2 .

Embodiment 3

[0055] Using a horizontal tube furnace with three temperature zones, it will contain 0.05g SnCl 2 The powder porcelain boat was placed in the upstream source area, 38cm away from the sample, and the porcelain boat filled with 0.05g CsCl powder was placed in the middle reaches of the source area, 16cm away from the sample, and the freshly peeled fluorophlogopite substrate was placed in the middle of the downstream growth area for Nanowire growth. Pump down the pressure of the tube furnace to 10 -3 Torr and Ar for 20 minutes, the gas flow is 50 sccm. Raise the temperature of the growth zone to 205°C for 5 minutes and anneal the SnCl 2 The temperature of the CsCl source area and the CsCl source area were respectively raised to 240° C. and 660° C., and grown for 20 minutes. After the growth is over, the source region and the growth region stop heating at the same time and gradually cool down to room temperature to obtain the nanowire CsSnCl 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com