Graphene electrode material and preparation method thereof

A graphene electrode, graphene technology, applied in the direction of graphene, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., to achieve the effect of easy installation and access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

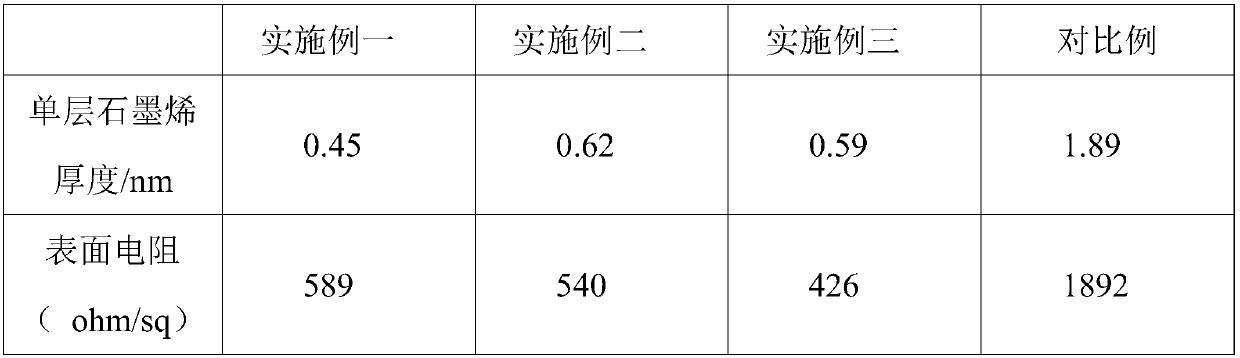

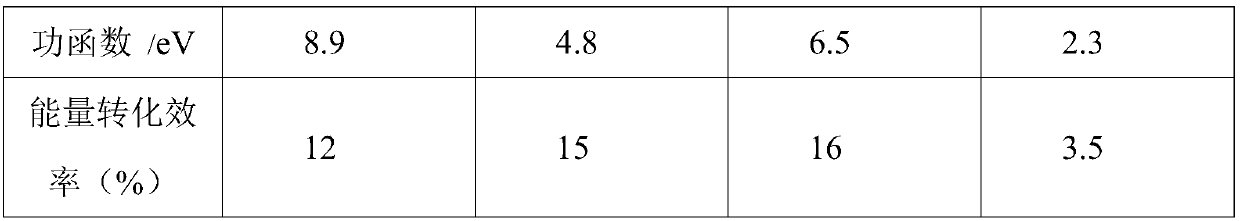

Embodiment 1

[0016] Wash the copper wire with a diameter of 20um in 95% ethanol, deionized water and 25% hydrochloric acid solution for 8 minutes, and then dry it in high-purity nitrogen; soak the dried copper wire in a concentration of 1mol / L Fe(NO 3 ) 3 In the aqueous solution, the immersion time is 45s, and the copper wire passes through the Fe(NO 3 ) 3 Corrosion occurs in the aqueous solution. After taking out the copper wire, stretch the two ends of the copper wire to keep the copper wire in a straight state; first rinse the corroded copper wire with a 25% hydrochloric acid solution, and then rinse it with deionized water , and finally dry it in high-purity nitrogen; place the copper wire on the quartz slide, and push the quartz slide to the position where the outer end of the quartz tube is close to the thermocouple. After pumping the inside of the device to a pressure ≤ 5Pa, then introduce hydrogen into the device to restore the internal pressure to normal pressure; then keep fee...

Embodiment 2

[0018] Wash the copper wire with a diameter of 20um in 95% ethanol, deionized water and 25% hydrochloric acid solution for 15 minutes, and then dry it in high-purity nitrogen; soak the dried copper wire in a concentration of 3mol / L of Fe(NO 3 ) 3 In the aqueous solution, the immersion time is 60s, and the copper wire passes through the Fe(NO 3 ) 3 Corrosion occurs in the aqueous solution. After taking out the copper wire, stretch the two ends of the copper wire to keep the copper wire in a straight state; first rinse the corroded copper wire with a 25% hydrochloric acid solution, and then rinse it with deionized water , and finally dry it in high-purity nitrogen; place the copper wire on the quartz slide, and push the quartz slide to the position where the outer end of the quartz tube is close to the thermocouple. After pumping the inside of the device to a pressure ≤ 5Pa, then introduce hydrogen into the device to restore the internal pressure to normal pressure; then keep...

Embodiment 3

[0021] Wash the copper wire with a diameter of 20um in 95% ethanol, deionized water and 25% hydrochloric acid solution for 12 minutes, and then dry it in high-purity nitrogen; soak the dried copper wire in a concentration of 2mol / L Fe(NO 3 ) 3 In the aqueous solution, the immersion time is 50s, and the copper wire passes through the Fe(NO 3 ) 3 Corrosion occurs in the aqueous solution. After taking out the copper wire, stretch the two ends of the copper wire to keep the copper wire in a straight state; first rinse the corroded copper wire with a 25% hydrochloric acid solution, and then rinse it with deionized water , and finally dried in high-purity nitrogen;

[0022] Place the copper wire on the quartz slide, and push the quartz slide to the position where the outer end of the quartz tube is close to the thermocouple. After pumping the inside of the device to a pressure ≤ 5Pa, then introduce hydrogen into the device to restore the internal pressure to normal pressure; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com