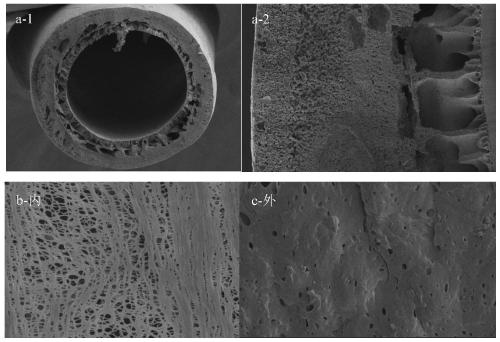

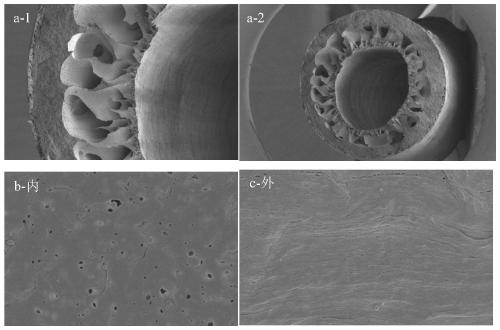

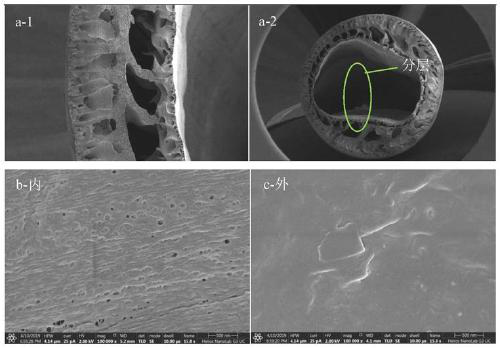

Novel double-layer hollow-fiber membrane for membrane distillation, preparation method therefor and application of novel double-layer hollow-fiber membrane

A double-layer hollow, fiber membrane technology, used in chemical instruments and methods, membranes, pervaporation, etc., can solve the problem of poor adhesion between inner and outer layers, inconsistent hydrophobic/hydrophilic properties, and reduced temperature polarization effects, etc. problem, to achieve the effect of excellent hydrophilicity, orderly arrangement of membrane pores, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] ① Preparation of inner and outer layer casting solution, core solution and outer gel bath

[0058] The inner layer casting liquid adopts polyvinylidene fluoride (PVDF6020), additive polyvinyl alcohol (PVA), solvent N-methylpyrrolidone (NMP) three substances by weight percentage 10wt%, 0.5wt%, 89.5wt% at 60 ℃ Mix evenly; the outer casting solution is made of polyvinylidene fluoride-hexafluoropropylene (P(VDF-co-HFP)), additive ethylene glycol (EG), solvent N,N-dimethylacetamide (DMAc) A kind of material is mixed uniformly at 60 ℃ by weight percent 15wt%, 5wt%, 80wt%; The composition of core liquid is the mixture of ethanol and water, and its weight percent is formulated by 50 / 50wt%; The composition of the first outer gel bath is The mixture of ethanol and water, its weight percent is prepared by 10 / 90wt%, the second outer gel bath is water.

[0059] ②Spinning of hollow fiber membrane

[0060] The core liquid, the inner layer casting liquid and the outer layer casting l...

Embodiment 2

[0065] Compared with Example 1, adjust the flow rate of casting liquid, core liquid and the first outer gel bath, specifically as follows:

[0066] ① Preparation of casting solution, core solution and outer gel bath

[0067] The inner layer casting solution is made of polyvinylidene fluoride (PVDF6020), additive polyvinylpyrrolidone (PVP), solvent N-methylpyrrolidone (NMP) and mixed at 60°C by weight percentage of 13wt%, 8wt%, 79wt% Uniform; the outer casting film uses polyvinylidene fluoride-hexafluoropropylene (P(VDF-co-HFP)), additive ethylene glycol (EG), solvent N,N-dimethylacetamide (DMAc) three substances 13wt%, 12wt%, and 75wt% were uniformly mixed at 60°C by weight percentage; the composition of the core liquid was a mixture of N-methylpyrrolidone, ethanol and water, and its weight percentage was 5wt%, 10wt%, 85wt%. The composition of the gel bath is a mixture of ethanol and water, and its weight percentage is formulated according to 20 / 80wt%, and the second outer ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com