Method for preparing nano ferrous disulfide microsphere with limited range

A technology of iron disulfide and microspheres, applied in iron sulfide, nanotechnology, electrical components, etc., can solve problems such as uneven wrapping, achieve excellent rate performance and cycle performance, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

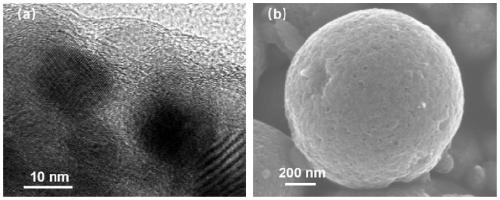

[0052] A method for preparing a negative electrode material for a nano-iron disulfide microsphere sodium-ion battery synthesized by confinement, comprising the following steps:

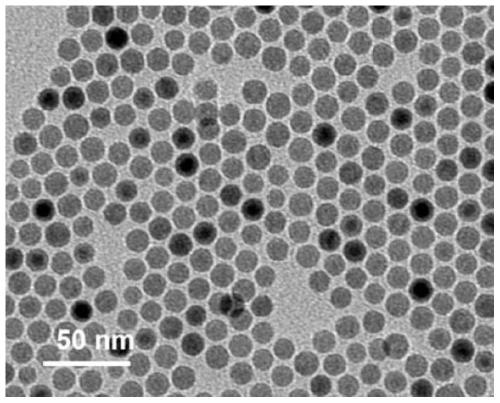

[0053]1) Dissolve 9g of ferric oleate and 3g of oleic acid in 50ml of octadecene, raise the temperature to 120°C under a nitrogen atmosphere, and vacuumize for 1 hour; then raise the temperature to 320°C under a nitrogen atmosphere, and maintain it for 1 hour. 18nm ferric oxide nanoparticles;

[0054] 2) After cooling down naturally, mix the reacted solution with the ethanol solution at a ratio of 1:1, centrifuge at 3000rpm and wash twice, and finally disperse into n-hexane (solid content is 50mg / ml);

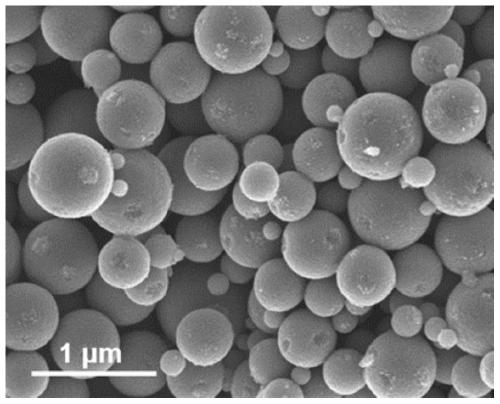

[0055] 3) Drop 1ml of iron ferric oxide nanoparticles into 10ml of 2% DTAB aqueous solution, homogenize at 5000rpm for 10 minutes, heat to 40°C, keep the temperature constant for 1 hour, and obtain ferric oxide microspheres after cooling and washing;

[0056] 4) Calcining the nano-iron ferric oxide mi...

Embodiment 2

[0065] A method for preparing a negative electrode material for a nano-iron disulfide microsphere sodium-ion battery synthesized by confinement, comprising the following steps:

[0066] 1) Dissolve 9g of iron oleate and 3g of oleic acid in 50ml of octadecene, raise the temperature to 120°C under a nitrogen atmosphere, and vacuumize for 1 hour; then raise the temperature to 320°C under a nitrogen atmosphere, and maintain it for 0.8 hours. 16nm ferric oxide nanoparticles;

[0067] 2) After cooling down naturally, mix the reacted solution with the ethanol solution at a ratio of 1:1, centrifuge at 3000rpm and wash twice, and finally disperse into n-hexane (solid content is 60mg / ml);

[0068] 3) Drop 1ml of iron ferric oxide nanoparticles into 10ml of 2% DTAB aqueous solution, homogenize at 5000rpm for 10 minutes, heat to 40°C, keep the temperature constant for 1 hour, and obtain ferric oxide microspheres after cooling and washing;

[0069] 4) Calcining the nano-iron ferric oxide ...

Embodiment 3

[0073] A method for preparing a negative electrode material for a nano-iron disulfide microsphere sodium-ion battery synthesized by confinement, comprising the following steps:

[0074] 1) Dissolve 9g of iron oleate and 3g of oleic acid in 50ml of octadecene, raise the temperature to 120°C under a nitrogen atmosphere, and vacuumize for 1 hour; then raise the temperature to 320°C under a nitrogen atmosphere, and maintain it for 1.2 hours. 19nm ferric oxide nanoparticles;

[0075] 2) After cooling down naturally, mix the reacted solution with the ethanol solution at a ratio of 1:1, centrifuge at 3000rpm and wash twice, and finally disperse into n-hexane (solid content is 50mg / ml);

[0076] 3) Drop 1ml of iron ferric oxide nanoparticles into 10ml of 2% SDS aqueous solution, homogenize at 5000rpm for 10 minutes, heat to 40°C, keep the temperature constant for 1 hour, and obtain ferric oxide microspheres after cooling and washing;

[0077] 4) Calcining the nano-iron ferric oxide m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com